Constant tension mechanism of expressage bag making machine

A technology of constant tension, bag making machine, applied in the field of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

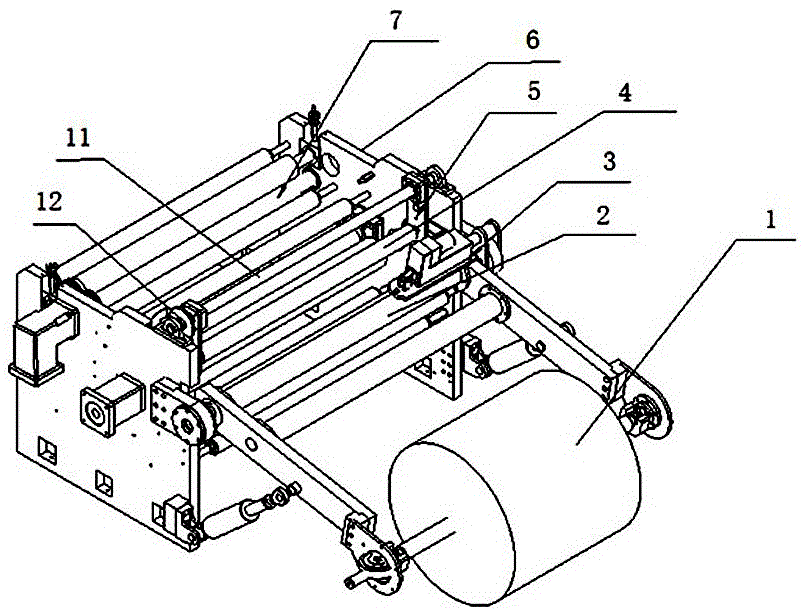

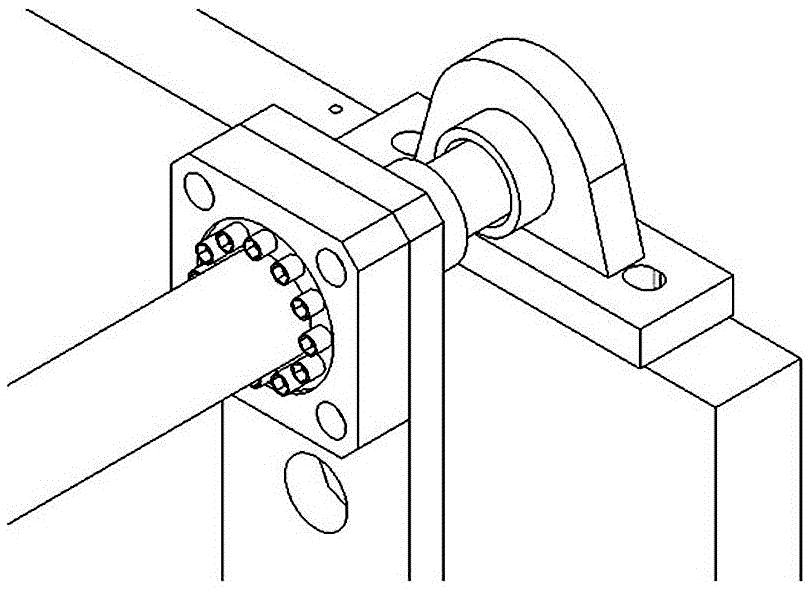

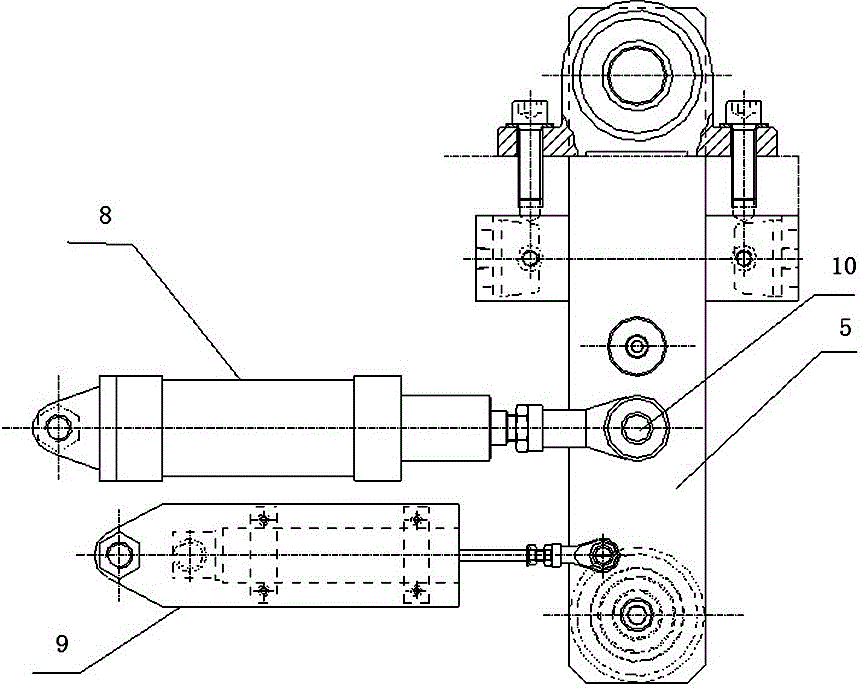

[0012] Such as Figure 1-Figure 3 As shown, a constant tension mechanism of an express bag making machine, the constant tension mechanism is arranged in the previous process of the first paper cutting mechanism of the bag making machine, including a swing arm 4, a swing roller 5, an angular displacement sensor 9, and a cylinder device 8 and joint bearing 10, the swing arm 5 is two oppositely arranged on the inner surface of the frame 6, the bottom between the two swing arms is connected with the swing roller 4, and the swing roller can rotate relative to the swing roller, in the middle of the swing arm 5 The positions are respectively connected to one end of the angular displacement sensor and the cylinder device, wherein one end of the cylinder device 8 is connected with the swing arm 5 by a joint bearing 10, and the other end of the cylinder device and the other end of the angular displacement sensor are respectively fixed on the frame. The setting of the joint bearing 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com