Underground coal mine narrow type operation vehicle

A technology for working vehicles and coal mines, which is applied to underground transportation, vehicle components, and the superstructure of trucks, etc., and can solve problems such as hidden safety hazards, harsh working environments, and high labor intensity for workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

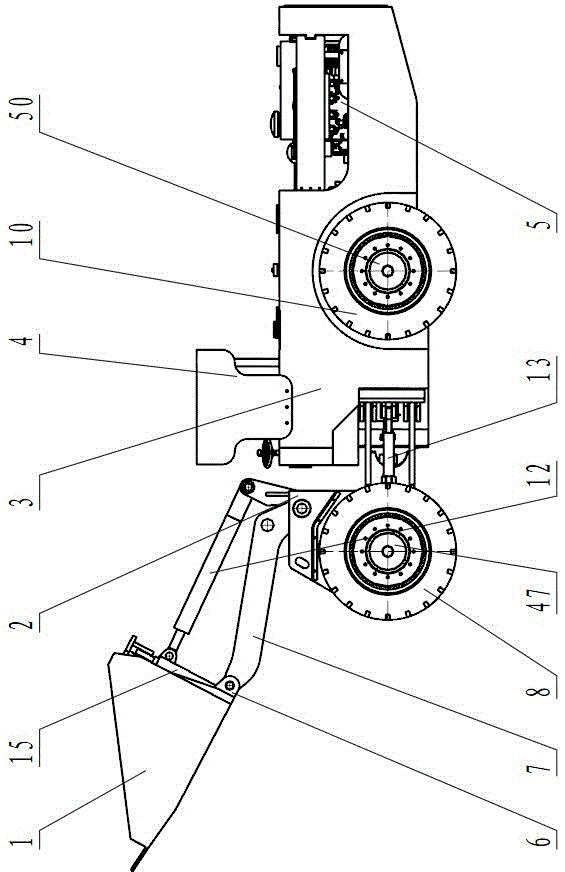

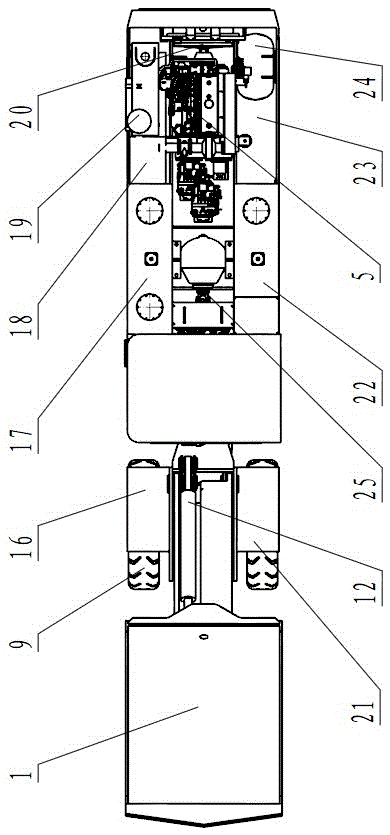

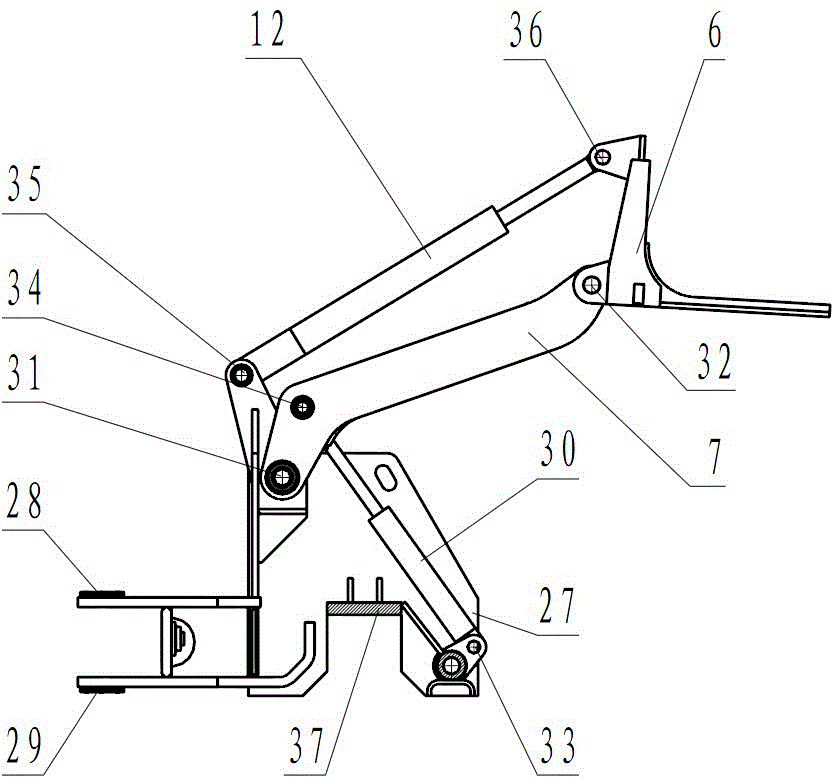

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] figure 1 , 2 Shown is the overall structure diagram of the vehicle. This type of coal mine underground narrow operation vehicle is powered by a diesel engine 5. At the same time, in order to meet the working requirements of the coal mine, the engine has been subjected to explosion-proof treatment, and the surrounding layout of the engine is reasonable; the front frame 2 and the rear frame 3 are hinged by a central slewing support The boom on the front frame realizes the lifting of the dumping bucket through the lifting cylinder 30 and the tilting cylinder 12; the front and rear wheels 8, 9, 10, 11 are solid filled tires to adapt to the harsh working environment underground; The steering of the whole vehicle is realized through the steering oil cylinder 13; the driver's cab 4 is placed on the front upper part of the rear frame 3, and adopts a horizontal layout, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com