Liquid resin transfer molding system and forming method thereof

A technology of transfer molding and liquid resin, which is applied in the field of liquid molding of resin-based composite materials. It can solve the problems of excessive porosity of composite parts, high local compaction, and increase the difficulty of exhausting preforms, so as to reduce porosity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

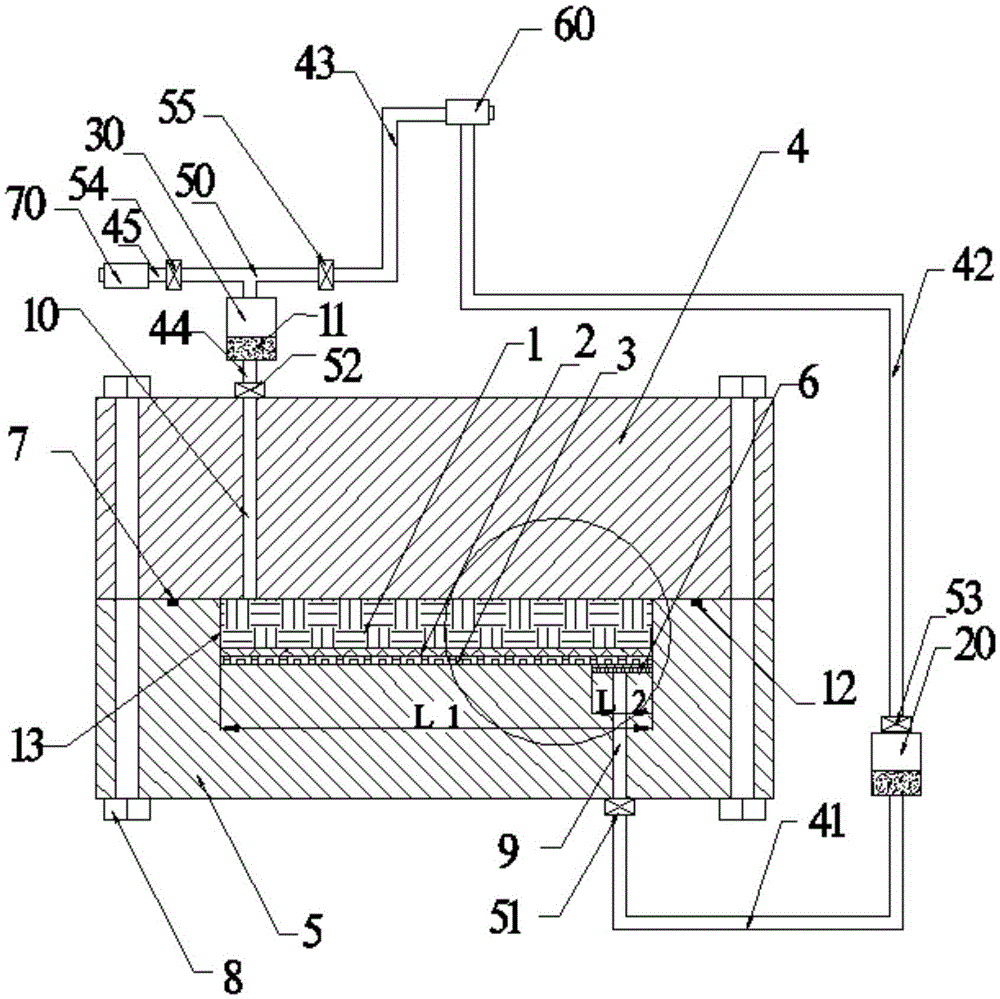

[0074] The preform 1 is a composite laminate structure, the material system is CF3031 / BA9912, and the fiber volume content of the material is 55%±3%; CF3031 is a T300 grade carbon fiber fabric with a specification of 3K produced by Shandong Weihai Development Company, and BA9912 resin It is a special resin developed for the liquid molding process by AVIC Composite Materials Co., Ltd. The external dimensions of the parts are: 500mm×500mm×3.65mm (length×width×thickness), and the design requires the porosity of the parts to be ≤1.5%. System layout such as figure 1 .

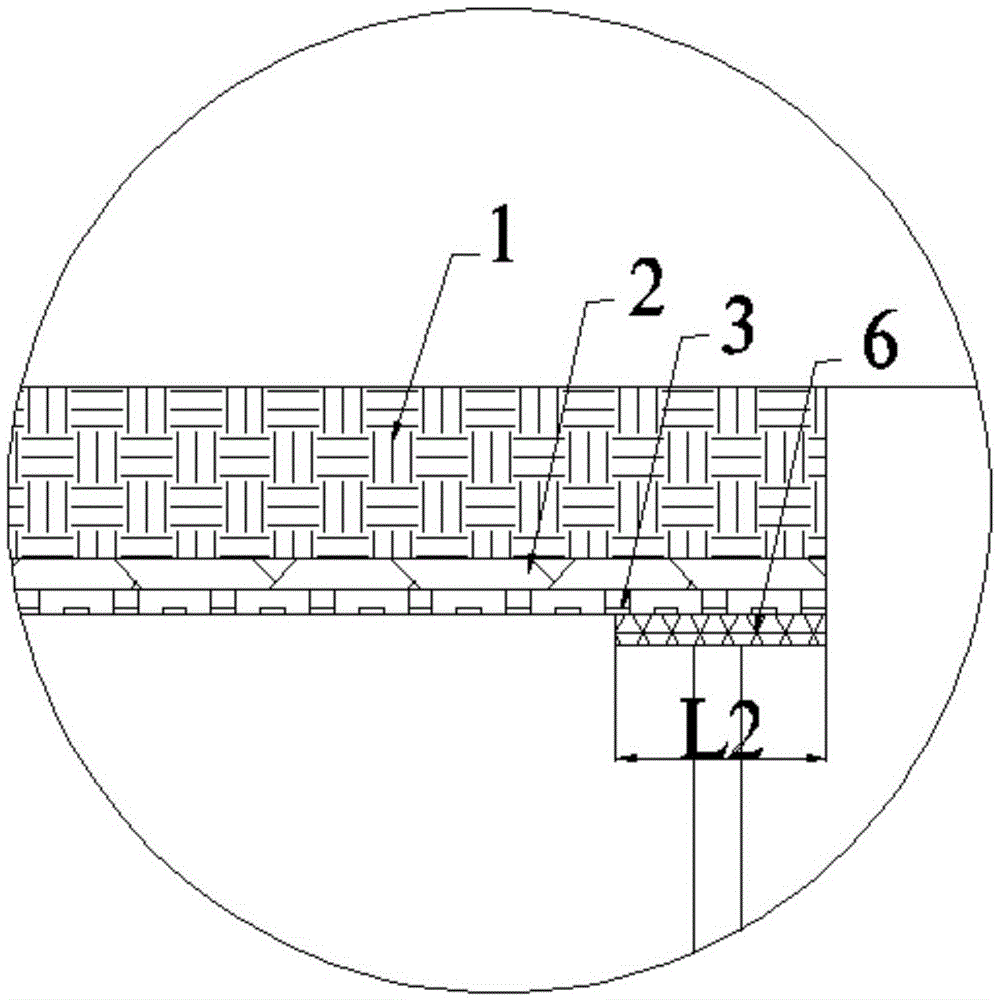

[0075] 1) On the side of the glue outlet channel 9 of the lower half-mold 5 close to the mold cavity 13, place the glue-permeable layer 6, the air-conducting layer 3 and the air-blocking glue layer 2 in sequence. The glue-penetrating layer 6 is a Q235 steel plate with a thickness of 5mm, including 5mm×5mm Density through holes, the length is 20mm, the air guide layer 3 is the greenflow guide net of Airtech Company,...

Embodiment 2

[0098] It was carried out as described in Example 1, and the only difference between Example 2 and Example 1 was that the material system in Example 2 was T800 / 5284, and the fiber volume content of the material was 56%±3%. Among them, T800 is the T800 carbon fiber with a specification of 12K produced by Toray Corporation of Japan, and 5284 resin is a special resin developed by AVIC Composite Materials Co., Ltd. for the liquid molding process. ×thickness); the design requires that the porosity content of the part is ≤2%. System layout such as figure 1 shown.

[0099] 1) On the side of the glue outlet channel 9 of the lower half-mold 5 close to the mold cavity 13, place the permeable glue layer 6, the air guide layer 3 and the air resistance glue layer 2 in sequence. The glue permeable layer 6 is an LY12CZ aluminum plate with a thickness of 3mm, including 3mm×3mm Density through holes, the length is 50mm, the air-guiding layer 3 is Airtech’s 90flow air-guiding mesh, and the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com