Axial-flow type centrifugal fan

A centrifugal fan and axial flow technology, which is used in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve the problems of limited wind pressure adjustment range, can not guarantee the safety and performance of fans, and achieves The effect of reducing maintenance frequency, occupying small space and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

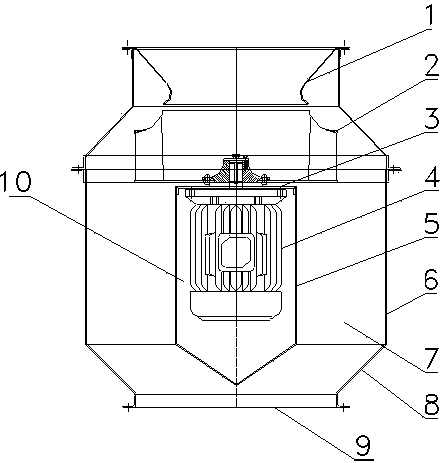

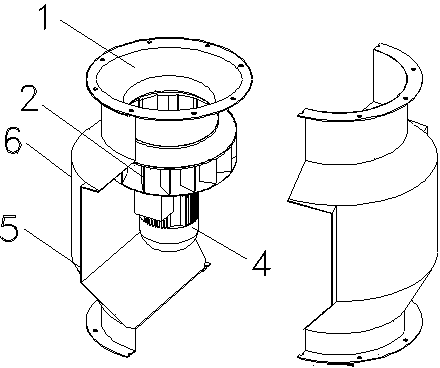

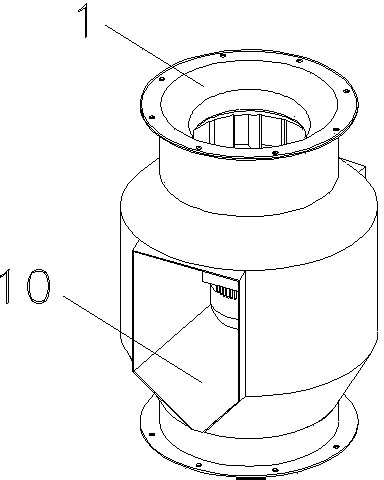

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-Figure 3 As shown, an axial-flow centrifugal fan includes a housing 8, the upper and lower ends of the housing 8 are respectively provided with an air inlet 1 and an air outlet 9, and the housing 8 includes an outer wall 6 that can form an air duct 7 And the inner wall 5, the centrifugal impeller 2 communicating with the air passage 7 is arranged below the air inlet 1, and the support plate 3 is arranged in the cavity 10 surrounded by the inner wall 5, and the support plate 3 is fixed There is a motor 4, the motor shaft of which passes through the support plate 3 and is connected to the centrifugal impeller 2, and the air inlet 1 is trumpet-shaped. By isolating the motor 4 from the workpiece and fluid, it can well play the role of waterproof, dustproof, explosion-proof and heat insulation, reduce the maintenance times of the motor 4, improve w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com