Copper pipe cutting device

A technology for cutting devices and copper pipes, which is applied in the direction of sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of increasing processes, uneven incisions, and affecting the normal use of copper pipes, so as to improve the uniformity of incisions and ensure The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

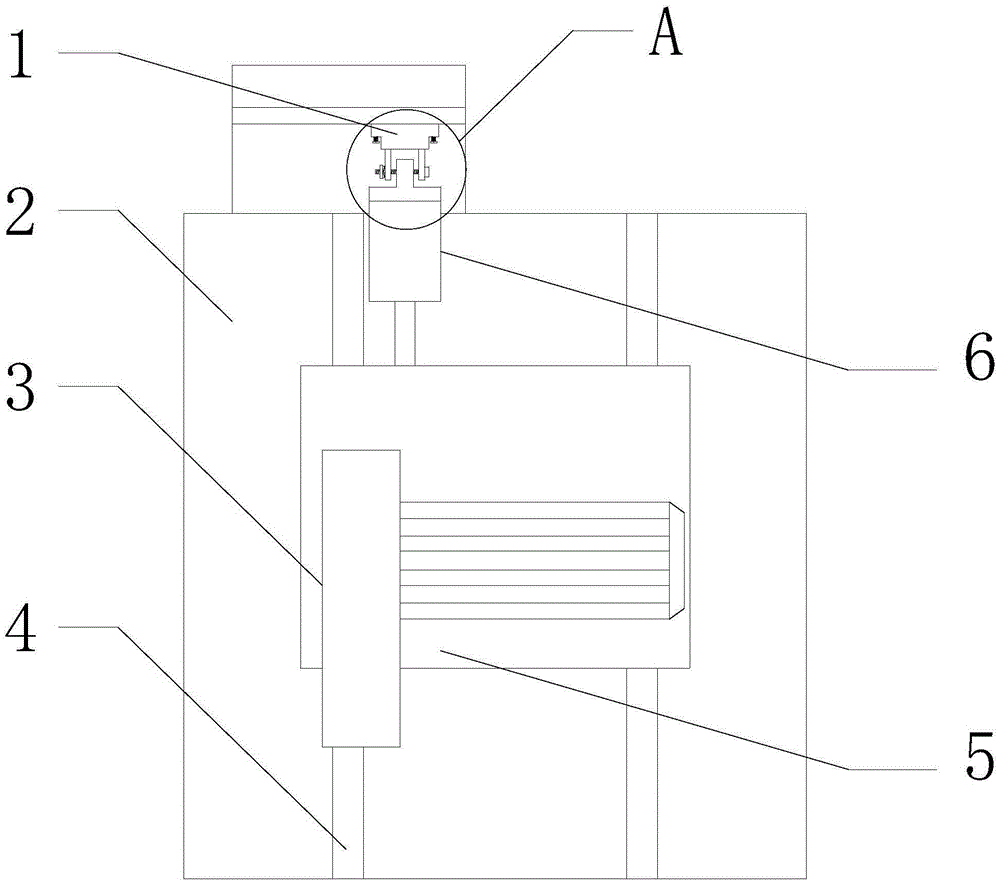

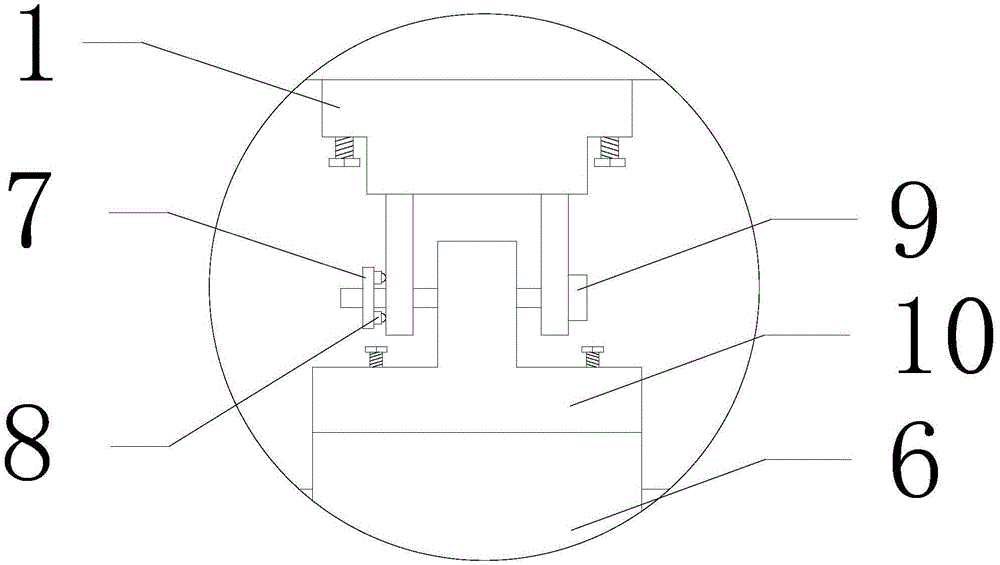

[0023] Embodiment: a copper pipe cutting device, its structure is as follows figure 1 and figure 2 As shown, including the base 2, the base is fixedly connected with the upper support 1 of 2, the upper support 1 is hinged with the cylinder 6 through the pin 9, and the piston rod of the cylinder 6 is connected with the slide plate 5;

[0024] The base 2 is provided with a slide rail 4, the back of the slide plate 5 is fixedly connected with the slide block (not shown in the figure), the slide block is slidably connected with the slide rail 4 to form a slide rail pair, and the electric saw 3 is fixedly connected to the slide plate 5 on;

[0025] Wherein, the sliding plate 5 is arranged vertically, and the cylinder 6 is also arranged vertically.

[0026] As a preferred structure, a positioning plate 7 is fixedly connected to one end of the pin shaft 9 without the upper cap. The positioning plate 7 has a plurality of joint balls 8 , and the spherical body of any joint ball 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com