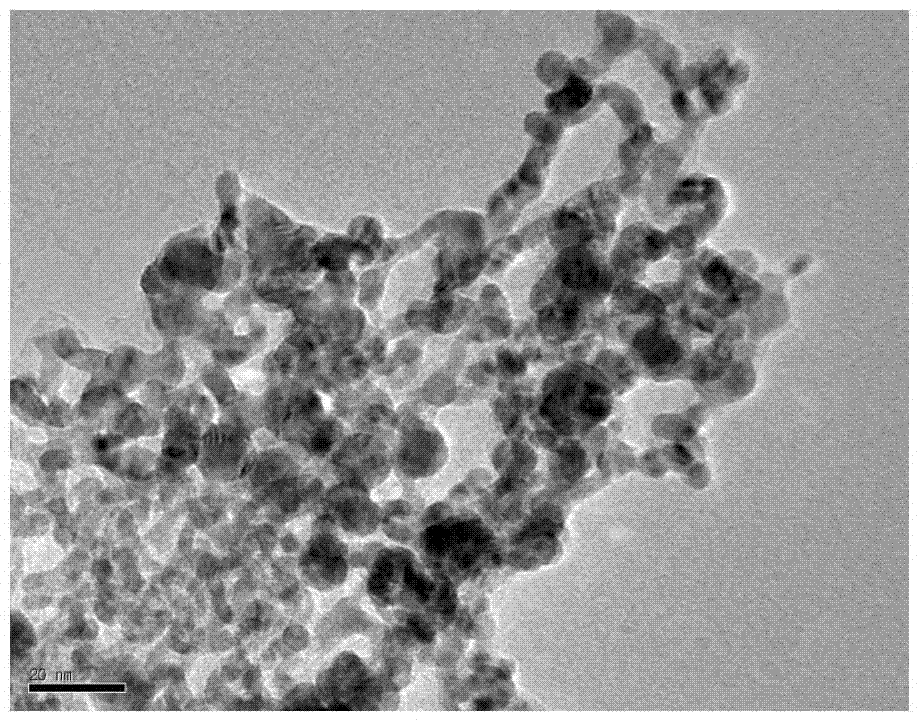

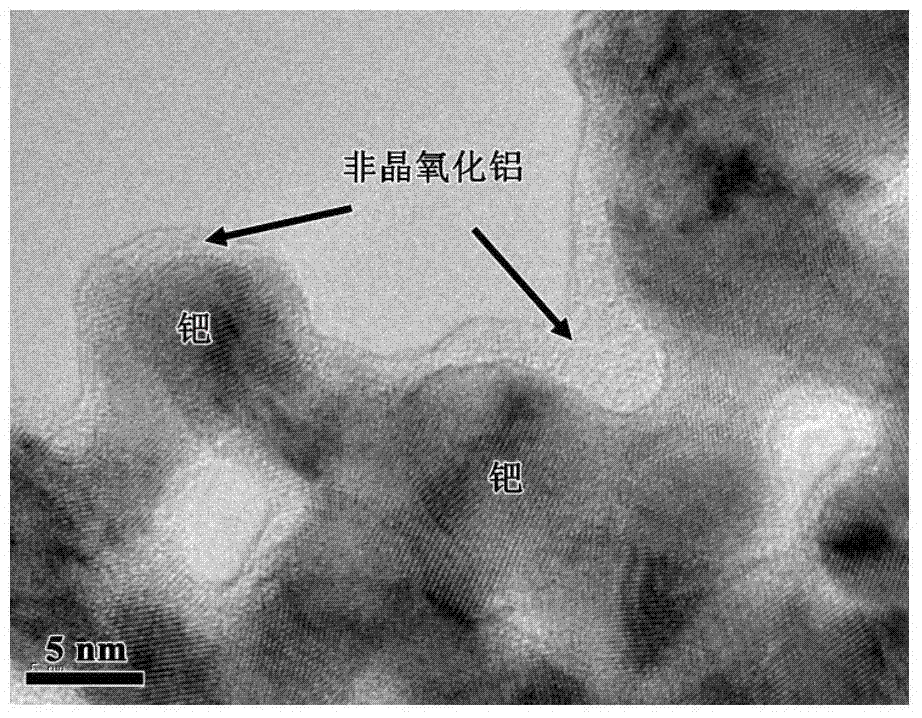

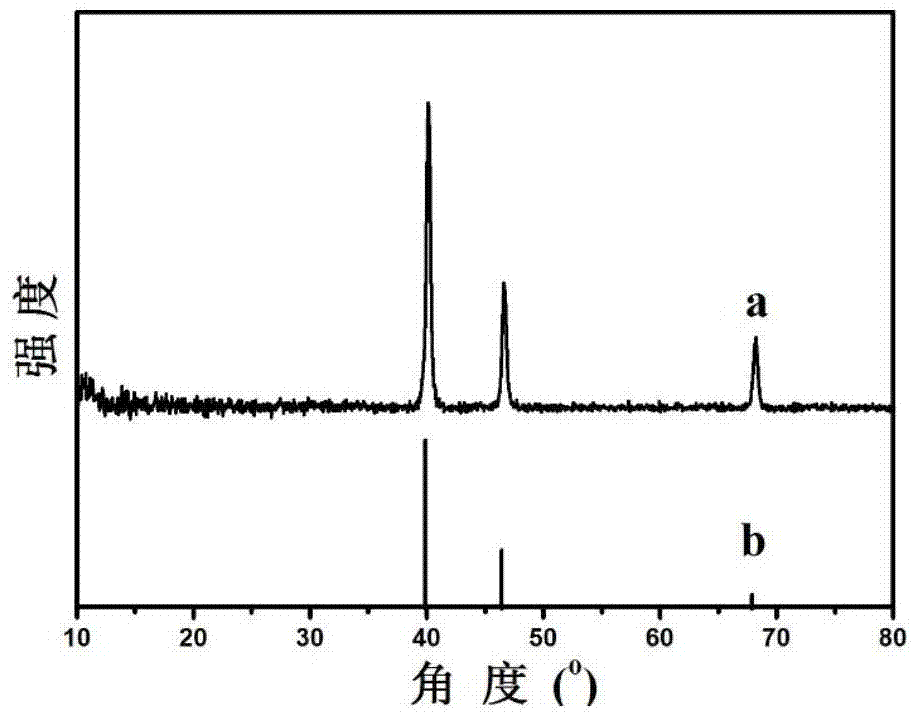

Alumina-coated palladium composite nanomaterial and preparation method thereof

A technology of composite nanomaterials and alumina, which is applied in the field of composite nanomaterials coated with alumina and palladium and its preparation, can solve the problems of easy "poisoning" of nano-Pd powder, cumbersome and complicated preparation methods, and inability to obtain products, and achieve production costs. low cost, simple preparation method and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The concrete steps of preparation are:

[0034] Step 1, first place the palladium target in a stirred 0.01mol / L aluminum nitrate solution; wherein, the aluminum nitrate solution is an aqueous aluminum nitrate solution. Then use a laser with a wavelength of 532nm (or 1064nm), a repetition rate of 1Hz, a pulse width of 15ns, and a power of 40mJ / pulse to irradiate the palladium target for 60min; wherein, the laser spot diameter is 0.5mm, and the emission wavelength is 532nm (or 1064nm ) laser is a Nd:YAG solid-state laser to obtain a mixed colloidal solution.

[0035] Step 2, the mixed colloidal solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotating speed is 1000r / min, and the time is 20min, and the washing process is to use deionized water or ethanol or Acetone washes the separated solid matter twice, the separation of solid matter during cleaning is centrifugation, an...

Embodiment 2

[0037] The concrete steps of preparation are:

[0038] Step 1, first place the palladium target in a 0.05mol / L aluminum nitrate solution under stirring; wherein, the aluminum nitrate solution is an aqueous aluminum nitrate solution. Then use a laser with a wavelength of 532nm (or 1064nm), a repetition rate of 5Hz, a pulse width of 12.5ns, and a power of 60mJ / pulse to irradiate the palladium target for 50min; wherein, the laser spot diameter is 1mm, and the emission wavelength is 532nm (or 1064nm ) laser is a Nd:YAG solid-state laser to obtain a mixed colloidal solution.

[0039] Step 2, the mixed colloidal solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotating speed is 3000r / min, and the time is 15min, and the washing process is to use deionized water or ethanol or Acetone washes the separated solid matter twice, the separation of the solid matter during cleaning is centrif...

Embodiment 3

[0041] The concrete steps of preparation are:

[0042]Step 1, first place the palladium target in a 0.2 mol / L aluminum nitrate solution under stirring; wherein, the aluminum nitrate solution is an aqueous aluminum nitrate solution. Then use a laser with a wavelength of 532nm (or 1064nm), a repetition rate of 10Hz, a pulse width of 10ns, and a power of 80mJ / pulse to irradiate the palladium target for 40min; wherein, the laser spot diameter is 1.5mm, and the emission wavelength is 532nm (or 1064nm ) laser is a Nd:YAG solid-state laser to obtain a mixed colloidal solution.

[0043] Step 2, the solid-liquid separation, washing and drying of the mixed colloidal solution are carried out successively; wherein, the solid-liquid separation process is centrifugation, the rotating speed is 6000r / min, and the time is 10min, and the washing process is to use deionized water or ethanol or Acetone washes the separated solid matter three times. The separation of the solid matter during clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com