Method for thermally upsetting and forming flange plate bolt head

A technology of hot heading and head, applied in the direction of bolts, threaded fasteners, connecting components, etc., which can solve the problems of long cycle, slow milling speed and low benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

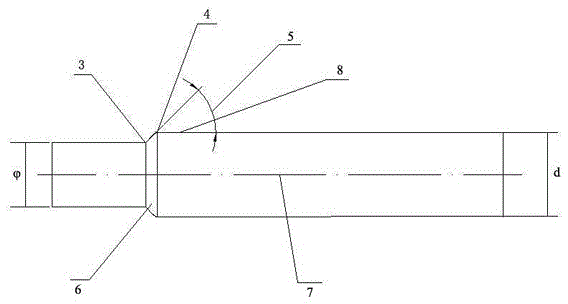

[0020] Such as Figure 1-2 As shown, a hexagonal flange bolt is randomly selected, and its basic data are: material 42CrMo (forging temperature range is 800-1150°C), hexagonal dimension S=12mm, rod diameter d=16mm;

[0021] First, the raw material is turned into a stepped shape;

[0022] Secondly, calculate the turning diameter φ=11.7 (S12-δ0.15-0.15=11.7) according to the size of the hexagonal opposite side and the amount of thermal expansion and contraction of the material, and turn the hexagonal material of the forming head into a small size, and then form the hexagonal small diameter part, The transition slope of the connection and the large-diameter part of the original material;

[0023] Turning the angle 5 between the transition slope 6 and the center line 7 at 30° and rounding the sharp angle 4 formed by the transition slope 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com