Sugarcane reaping and squeezing machine

A sugarcane harvesting and squeezing machine technology, which is applied to harvesters, extracting juice from sugarcane, cutters, etc., can solve the problems that affect the economic benefits of sugarcane farmers and sugar enterprises, the loss of sugarcane sugar, and increase transportation costs, etc., to achieve Reduce sugarcane transportation links, reduce labor intensity, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

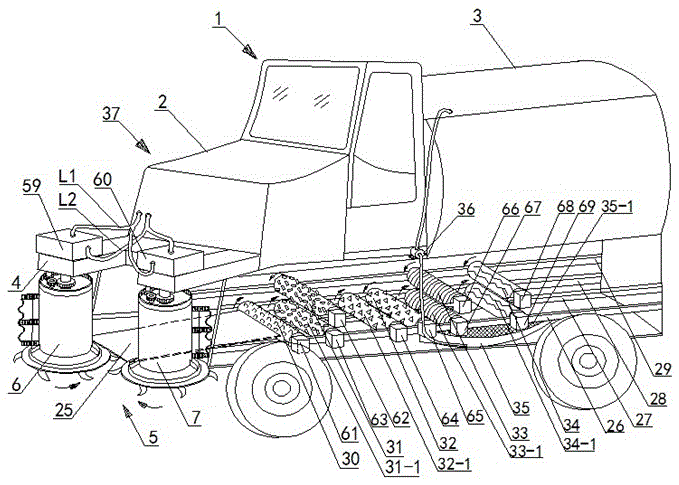

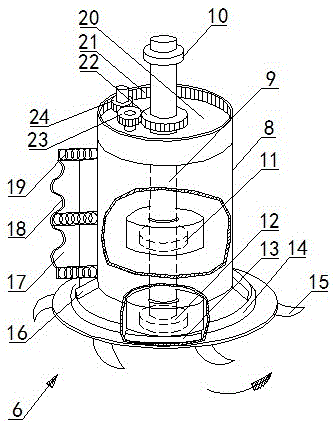

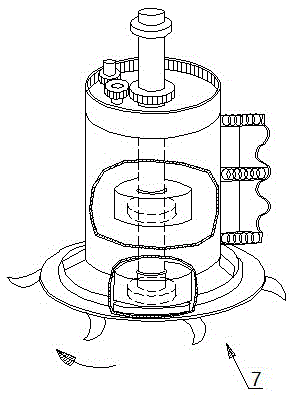

[0018] refer to figure 1 , figure 2 , image 3 , figure 1 is a perspective view of the present invention, figure 2 It is a three-dimensional schematic diagram of the left harvesting mechanism of the sugarcane harvesting device of the present invention, image 3 It is a three-dimensional schematic diagram of the right harvesting mechanism of the sugarcane harvesting device of the present invention, from figure 1 , figure 2 and image 3 It can be seen that the specific structure of the present invention includes a diesel-powered main engine 1, a main engine head box 2, and a main engine rear storage tank 3. The specific embodiment: the front end of the main engine head box 2 is provided with a left and right convex arm 4, and the left and right convex arms 4 The bottom of sugarcane harvesting device 5 is provided with; This sugarcane harvesting device 5 is made up of left harvesting mechanism 6, right harvesting mechanism 7 identical in structure; This left harvesting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com