Novel organic compound and organic light-emitting device comprising the same

An organic compound and compound technology, applied in organic chemistry, light-emitting materials, electrical components, etc., can solve the problems of high driving voltage, short service life, practical difficulties, etc., and achieve low driving voltage, long service life, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

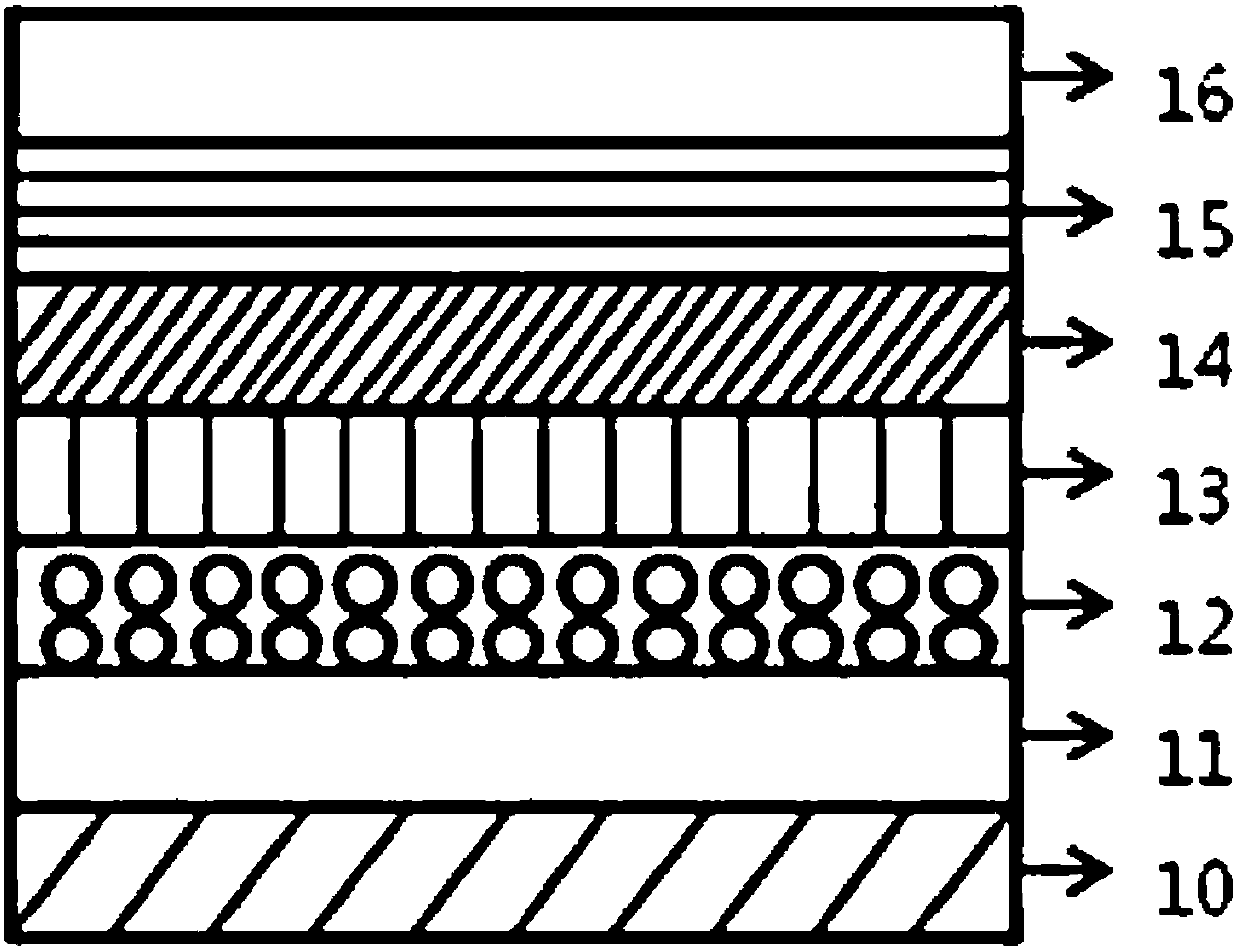

[0237] Ultrasonic cleaning with distilled water has a thickness of Indium Tin Oxide (ITO) thin film glass substrate. After cleaning with distilled water, use solvents such as isopropanol, acetone, and methanol to perform ultrasonic cleaning and dry, then transport to a plasma cleaner and use oxygen plasma to clean the above-mentioned substrate for 5 minutes, and then use thermal vacuum evaporation The thermal evaporator made a thickness of The HATCN film as the hole injection layer and the thickness is HT01 film as a hole transport layer. Next, a film with a thickness of The film is used as a buffer layer and is doped with BH01:BD01 at 5% to make a thickness of film as the above-mentioned light-emitting layer.

[0238] Next, with Alq 3 (Tris(8-hydroxyquinoline)aluminum): Liq=1:1 to produce a thickness of After the film was used as the electron transport layer, a thickness of The LiF film and the thickness is An aluminum (Al) film was used to seal (Encapsulat...

Embodiment 2 to 13

[0240] Compounds 2 to 13 were used instead of Compound 1, and a buffer layer film was fabricated in the same manner as in Example 1, thereby fabricating an organic light-emitting device.

Embodiment 14

[0244] Ultrasonic cleaning with distilled water has a thickness of Indium Tin Oxide (ITO) thin film glass substrate. After cleaning with distilled water, use solvents such as isopropanol, acetone, and methanol to perform ultrasonic cleaning and dry, then transport to a plasma cleaner and use oxygen plasma to clean the above-mentioned substrate for 5 minutes, and then use thermal vacuum evaporation The thermal evaporator made a thickness of The HATCN film as the hole injection layer and the thickness is HT01 film as a hole transport layer. Next, a film with a thickness of The film as a buffer layer and compound 14: Ir(ppy) 3 (Tris(2-phenylpyridine)iridium) was doped at 9% to produce a thickness of film as the above-mentioned light-emitting layer. Next, with Alq 3 (Tris(8-hydroxyquinoline)aluminum): Liq=1:1 to produce a thickness of After the film was used as the electron transport layer, a thickness of The LiF film and the thickness is An aluminum (Al) film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com