Processing method of circuit board

A processing method and circuit board technology, which is applied in the reinforcement of conductive patterns, printed circuits, and printed circuit manufacturing, etc., can solve problems such as under-corrosion, over-corrosion, and film problems, achieve low requirements for accuracy, and avoid film problems. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

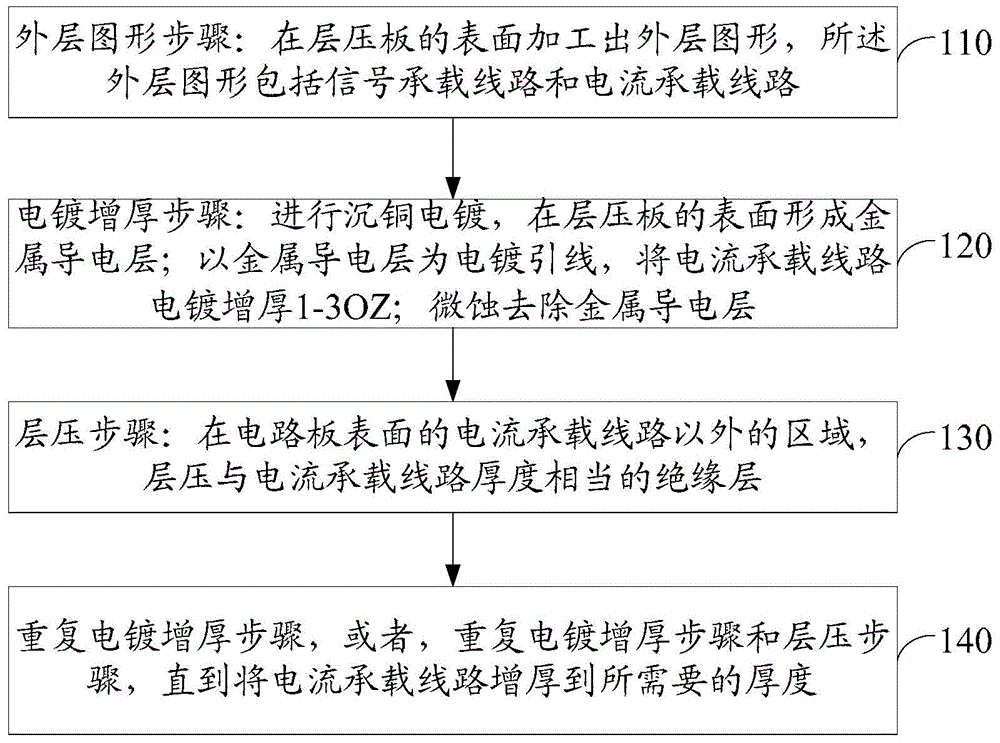

[0023] Please refer to figure 1 , an embodiment of the present invention provides a method for processing a circuit board, which may include:

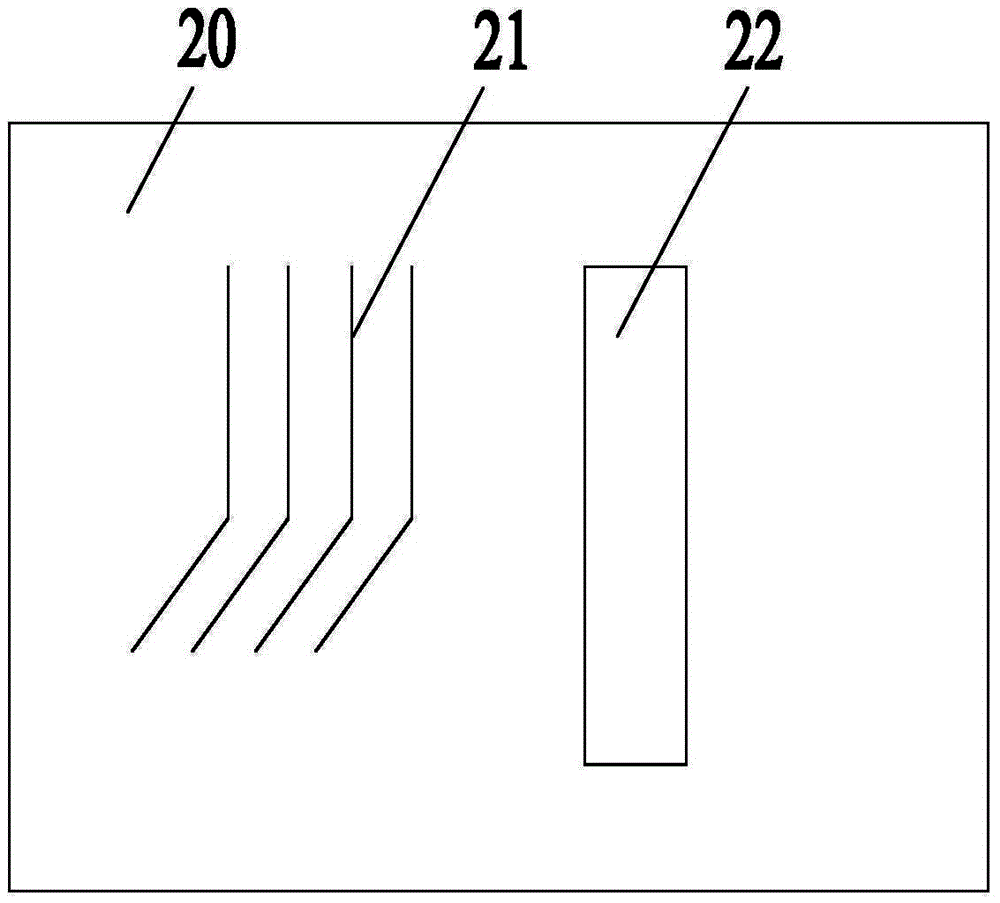

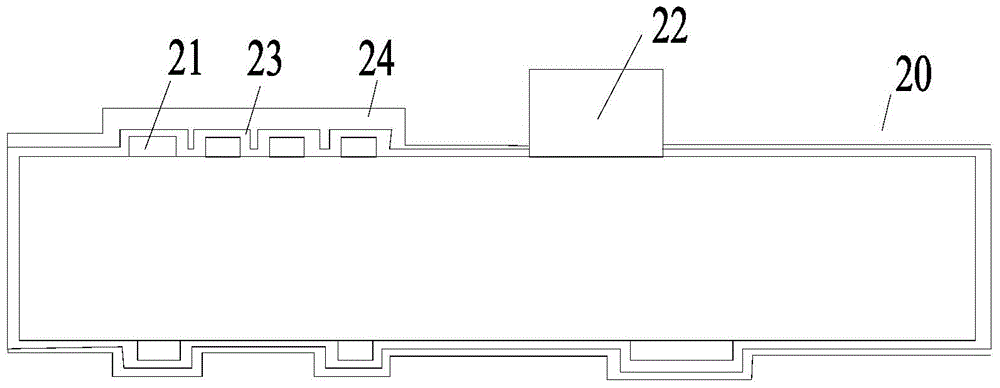

[0024] 110. The step of outer layer graphics: processing the outer layer graphics on the surface of the laminated board, the outer layer graphics include signal carrying lines and current carrying lines.

[0025] In this embodiment, the laminate can be blanked or processed according to conventional techniques, and the laminate can be a single-sided copper-clad laminate or a double-sided copper-clad laminate, or a multi-layer board based on double-sided copper-clad laminates. In this paper, the double-sided copper clad laminate is taken as an example, and the double-sided copper clad laminate with the corresponding thickness of the copper foil layer can be cut according to the thickness of the required outer layer pattern as a laminate. The thickness of the surface metal layer of the laminate can be less than or equal to 1OZ.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com