Automobile engine exhaust system

A technology of automobile engine and exhaust system, which is applied in the direction of engine components, combustion engines, machines/engines, etc. It can solve complex problems, without considering the way of generating electric energy and power supply strategy, and without considering the way of heat collection of heat collecting modules, etc. problem, achieve the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

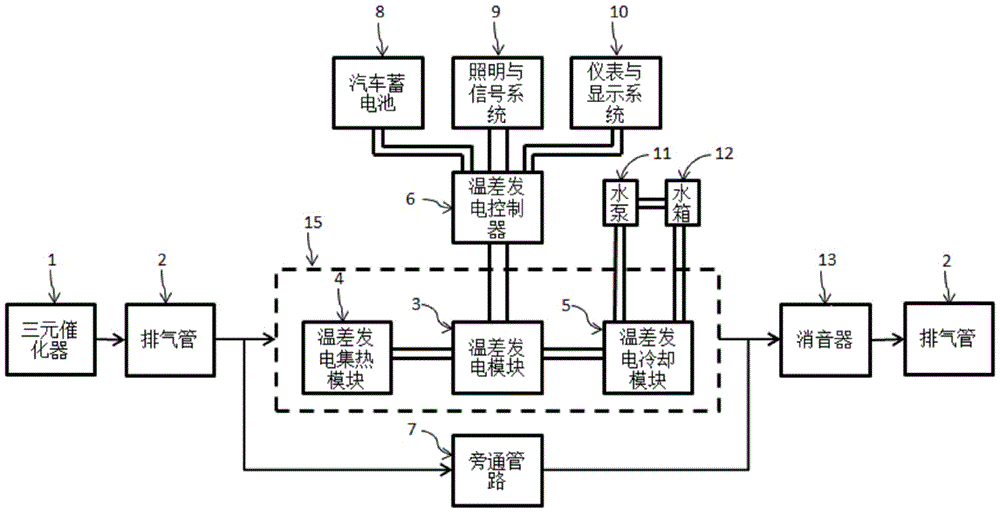

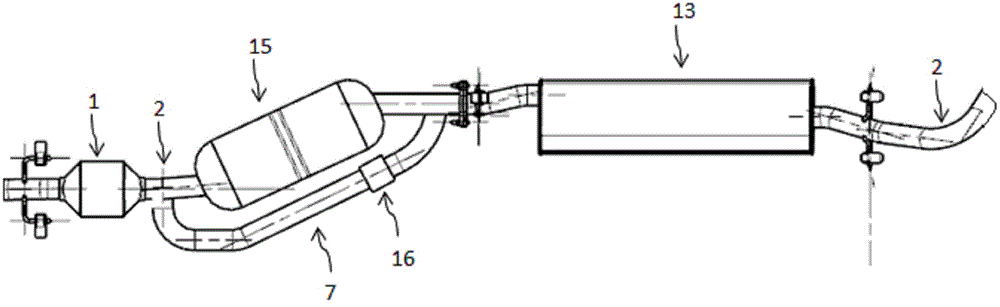

[0026] see figure 1 and figure 2 As mentioned above, an embodiment of the present invention provides an automobile engine exhaust system.

[0027] It includes a three-way catalytic converter 1 connected behind the flexible section of the engine exhaust system, connected to the exhaust pipe 2, and connected to the thermoelectric power generation device 15.

[0028] The thermoelectric power generation device 15 includes a thermoelectric power generation heat collection module 4 , a thermoelectric power generation cooling module 5 , a thermoelectric power generation module 3 , and a thermoelectric power generation controller 6 .

[0029] The heat collection module 4 of thermoelectric power generation adopts fin-type high thermal conductivity material. The fins extend into the exhaust pipe 2, fully contact with the exhaust waste heat, absorb the exhaust waste heat, and store it in the heat collection module with high thermal conductivity. Material slab.

[0030] The thermoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com