Electric connector assembly

A technology for electrical connectors and components, applied in the direction of connection, parts of connecting devices, electrical components, etc., can solve the problems of inconvenient disassembly and assembly of electrical connectors, complicated locking structure of connecting nuts, etc., and achieve the process of insertion and disassembly. Convenient, simple structure, improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

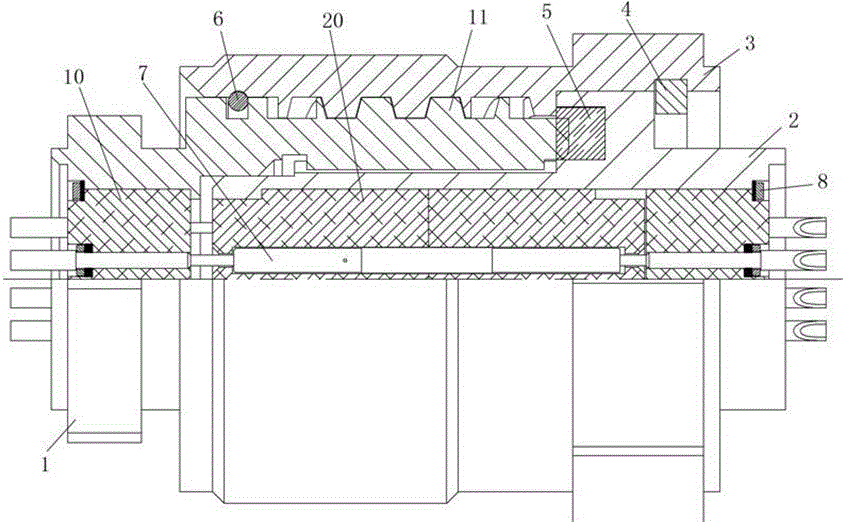

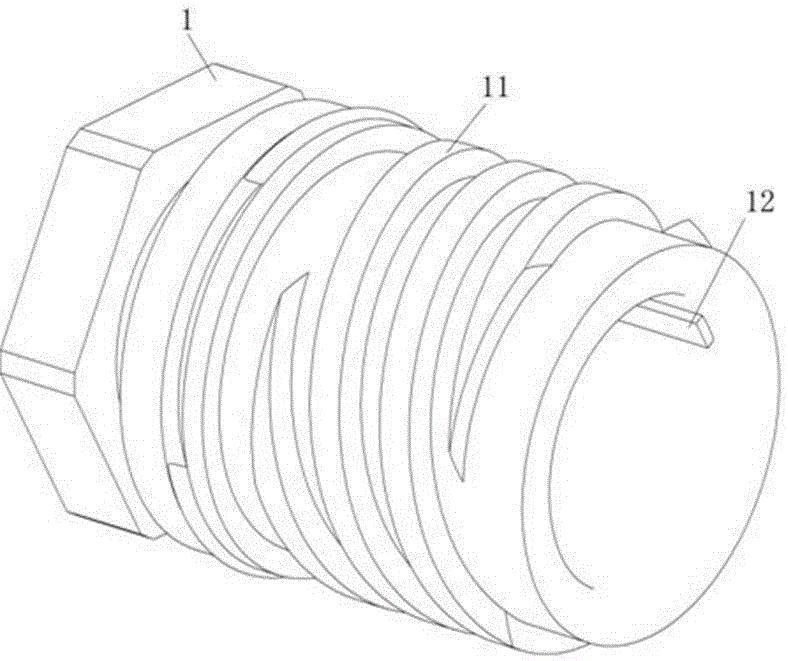

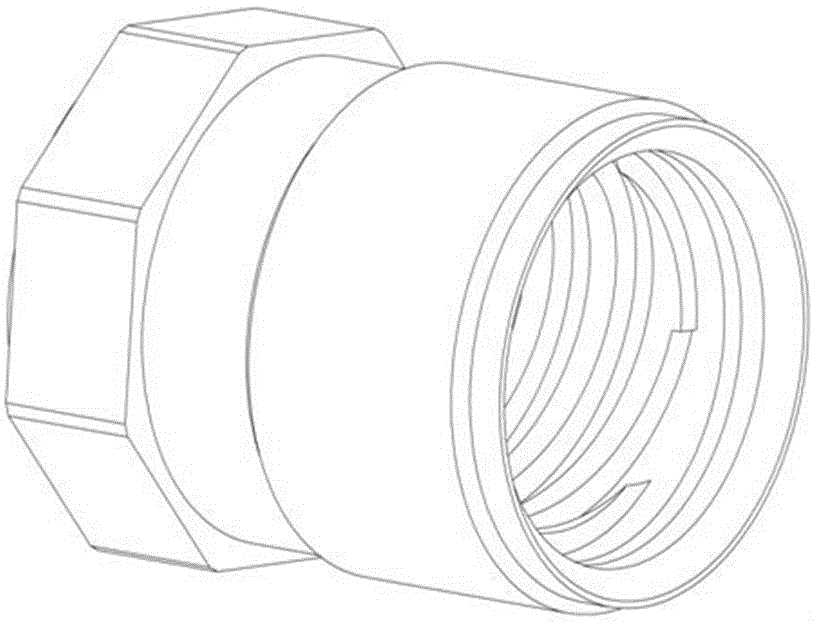

[0021] Embodiment 1 of the electrical connector assembly of the present invention: as Figure 1-6 As shown, it includes a plug, a socket and a connecting nut connecting the plug and socket. The plug includes a plug housing 2 and a jack insulator 20 disposed in the plug housing 2. The plug housing 2 is a hollow cylindrical structure extending left and right. The hole insulator 20 is located in the cavity, and the jack insulator 20 is fixed with a double-headed jack 7 extending left and right. The side is provided with a sealing ring installation groove opening to the left, and a high-purity graphite sealing ring 5 is installed in the sealing ring installation groove. The right end of the right end of the top pressure seal fits the top pressure fitting surface to ensure the tightness of the connection between the plug and the socket. The left end extension of the plug housing 2 has an outer peripheral surface for plugging and matching with the socket. The left end of the plug ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com