Positive electrode of safe lithium-ion power battery and lithium-ion battery comprising positive electrode

A power battery, lithium ion technology, applied in battery electrodes, electrode collector coatings, secondary batteries, etc., can solve the problem of poor electrochemical performance and stability of batteries, affecting battery quality and service life, and thermal shrinkage of ceramic diaphragms High problems, achieve good liquid absorption and liquid retention rate, reduce the probability of thermal runaway, and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

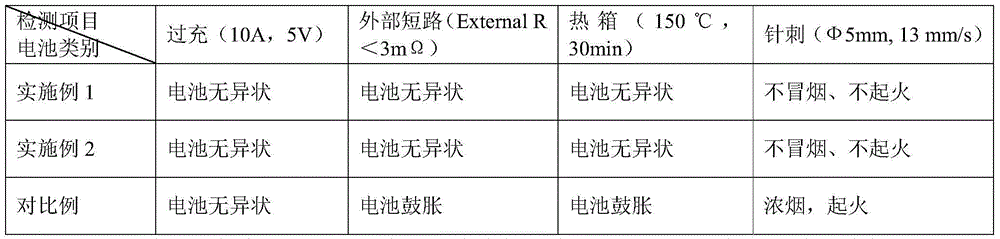

Examples

Embodiment 1

[0050] Preparation of ceramic slurry: Weigh 40 parts by weight of boehmite, 8 parts by weight of polyvinylidene fluoride, 2 parts by weight of polyvinylpyrrolidone, and 50 parts by weight of nitrogen methyl pyrrolidone, add them successively, adopt high-speed dispersion, stir for 6 Hours to mix the slurry evenly. Wherein, the particle size range of the inorganic ceramic particles is 0.5 μm≤D50≤1 μm.

[0051] Preparation of positive electrode sheet: Mix nickel-cobalt-manganese ternary material, conductive agent, and binder, add solvent and stir to form a slurry, and evenly coat it on the aluminum foil of the positive electrode collector. After drying, it is rolled with a rolling machine to make a positive electrode sheet. Then, the ceramic slurry in the previous step was evenly coated on the positive electrode sheet, and the coating thickness was 4 μm on both sides. And place the pole piece in a vacuum oven to dry at a temperature of 110 degrees centigrade for 10 hours.

[0...

Embodiment 2

[0058] Preparation of ceramic slurry: Weigh 38 parts by weight of diaspore, 8 parts by weight of styrene-butadiene rubber, 2 parts by weight of carboxymethyl cellulose, 2 parts by weight of polyvinylpyrrolidone, and 50 parts by weight of deionized water, add successively , take high-speed dispersion and stir for 6 hours to make the slurry evenly mixed. The particle size range of the inorganic ceramic particles is 0.3 μm≤D50≤0.8 μm.

[0059] Preparation of positive electrode sheet: Mix nickel-cobalt-manganese ternary material, conductive agent, and binder, add solvent and stir to form a slurry, and evenly coat it on the aluminum foil of the positive electrode collector. After drying, it is rolled with a rolling machine to make a positive electrode sheet. Then, the ceramic slurry in the previous step was evenly coated on the positive pole piece, one side was coated, and the coating thickness was 6 μm. And place the pole piece in a vacuum oven to dry at a temperature of 90 degr...

Embodiment 3

[0074] Prepare ceramic slurry: weigh 20 parts by weight of boehmite, 20 parts by weight of diaspore, 8 parts by weight of polyvinylidene fluoride, 2 parts by weight of polyvinylpyrrolidone, and 50 parts by weight of nitrogen methyl pyrrolidone, successively Add, disperse at high speed, and stir for 6 hours to make the slurry evenly mixed. The particle size range of the inorganic ceramic particles is 0.1 μm≤D50≤0.5 μm.

[0075] Preparation of positive electrode sheet: Mix nickel-cobalt-manganese ternary material, conductive agent, and binder, add solvent and stir to form a slurry, and evenly coat it on the aluminum foil of the positive electrode collector. After drying, it is rolled with a rolling machine to make a positive electrode sheet. Then, the ceramic slurry in the previous step was evenly coated on the positive electrode sheet, and the coating was applied on both sides, and the coating thickness on each side was 8 μm. And place the pole piece in a vacuum oven to dry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com