A thin film pressure transducer and a manufacturing method thereof

A thin-film pressure and sensor technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of damage to the sensitive core, limited ability to instantaneous temperature shock, etc., to improve the ability to withstand instantaneous temperature shock and buffer against temperature shock Ability to measure pressure smooth and true effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

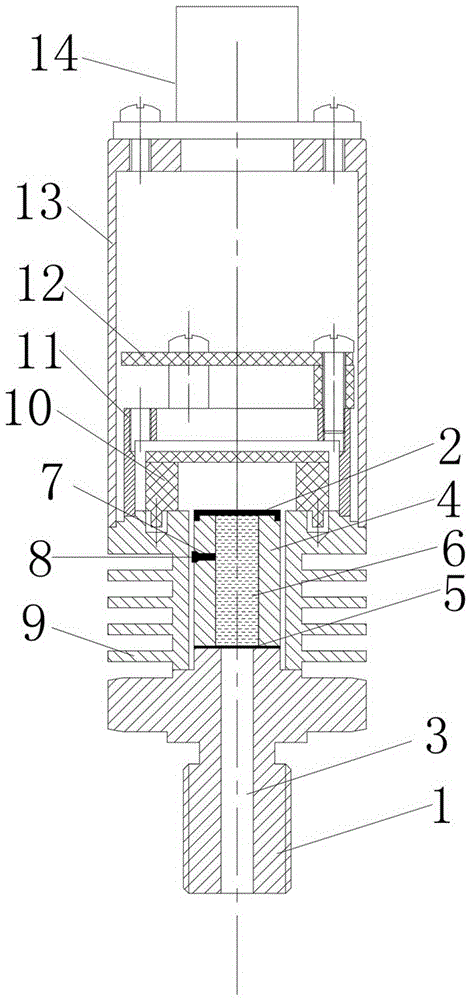

[0031] Such as figure 1 As shown, the thin-film pressure sensor of this embodiment includes a base 1 and a sensitive core 2, a pressure introduction hole 3 is provided in the base 1, and a pressure sensor for transmitting medium pressure is also provided between the base 1 and the sensitive core 2. A buffer component that blocks the temperature transfer of the medium. Due to the existence of the buffer component, the distance between the pressure introduction hole and the sensitive core is increased, and the measuring medium first transmits the pressure to the buffer component, and then the buffer component transmits the pressure to the sensitive core. When the measuring medium transmits the pressure to the buffer component, the transient heat transmitted by the measuring medium is absorbed by the buffer component, the temperature of the buffer component changes slowly, and the temperature of the sensitive core can basically remain unchanged, that is, the buffer component can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com