Pilot-Operated Pressure Relief Valve with Lateral Pressure Connection

A pressure, valve body technology for the field of pre-controlled pressure limiting valves with lateral pressure connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

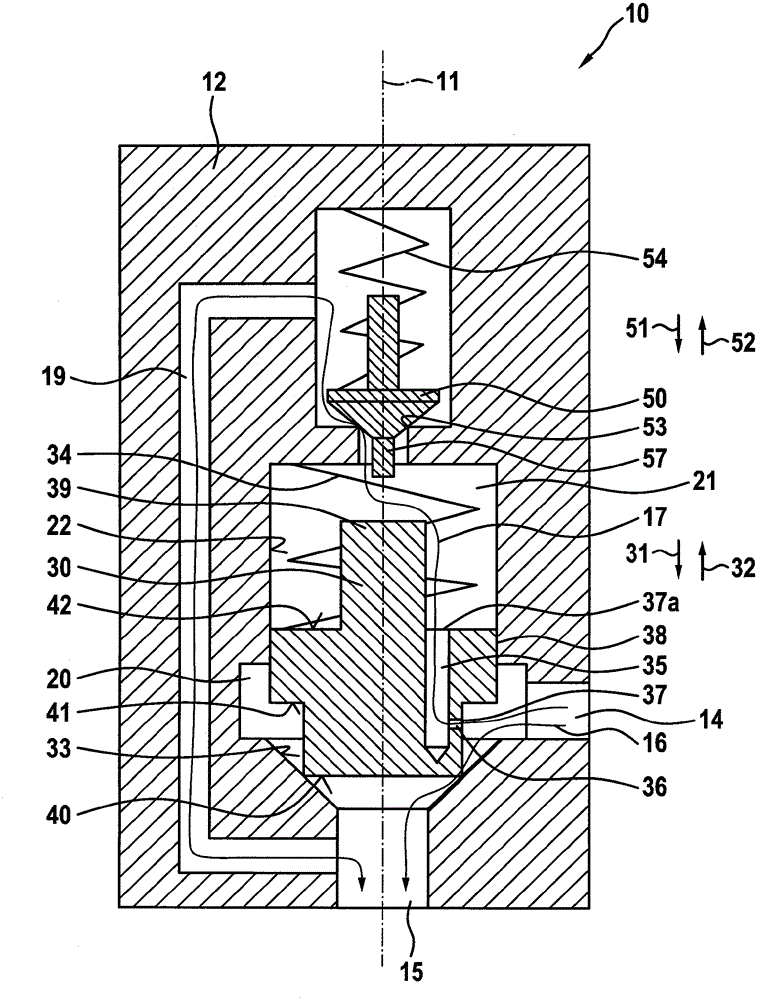

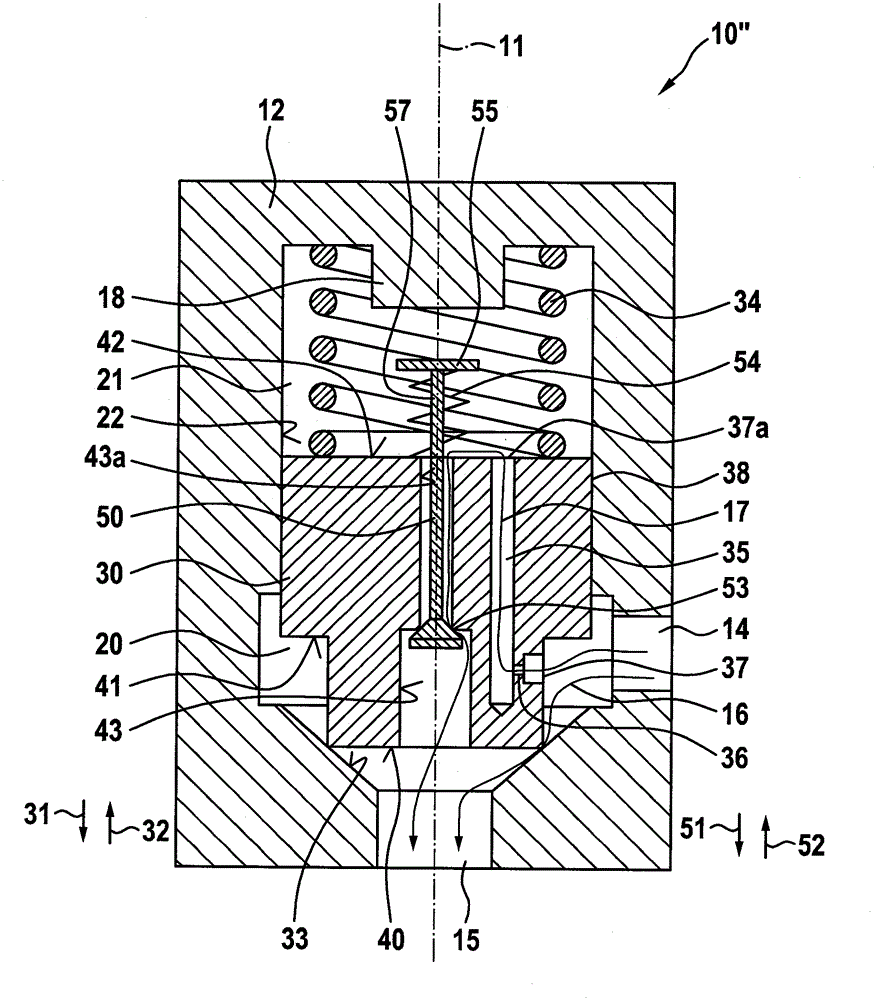

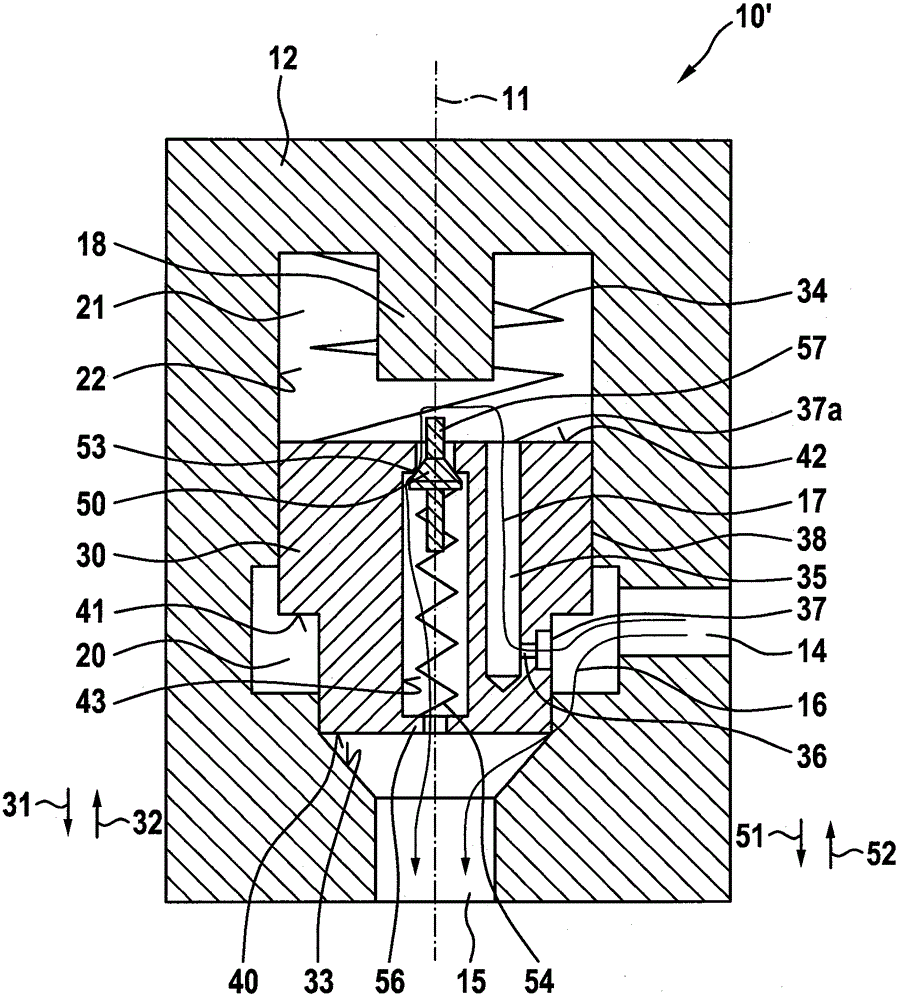

[0062] figure 1A roughly schematic sectional view of a valve 10 according to a first embodiment of the invention is shown. The valve 10 has a housing 12 in which a first valve body 30 is accommodated so as to be movable along a longitudinal axis 11 . In this case, the first valve body 30 is guided with little play in the cylindrical piston bore 22 with respect to the longitudinal axis 11 . Assigned to first valve body 30 is a first valve seat 33 , which is configured conically with respect to longitudinal axis 11 . The first valve body 30 is designed in the manner of a stepped piston, wherein the first valve body can seal off the first valve seat 33 with its smaller end face 40 in a sealing manner.

[0063] The second connection point 15 is arranged on the end face with respect to the longitudinal axis 11 relative to the first valve body 30 . The second connection point 15 is formed by a cylindrical bore with respect to the longitudinal axis 11 , which opens into the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com