Turbo engine with power turbine

A technology of turbine engine and power turbine, applied in engine components, combustion engine, engine lubrication, etc., can solve problems such as unreliable transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

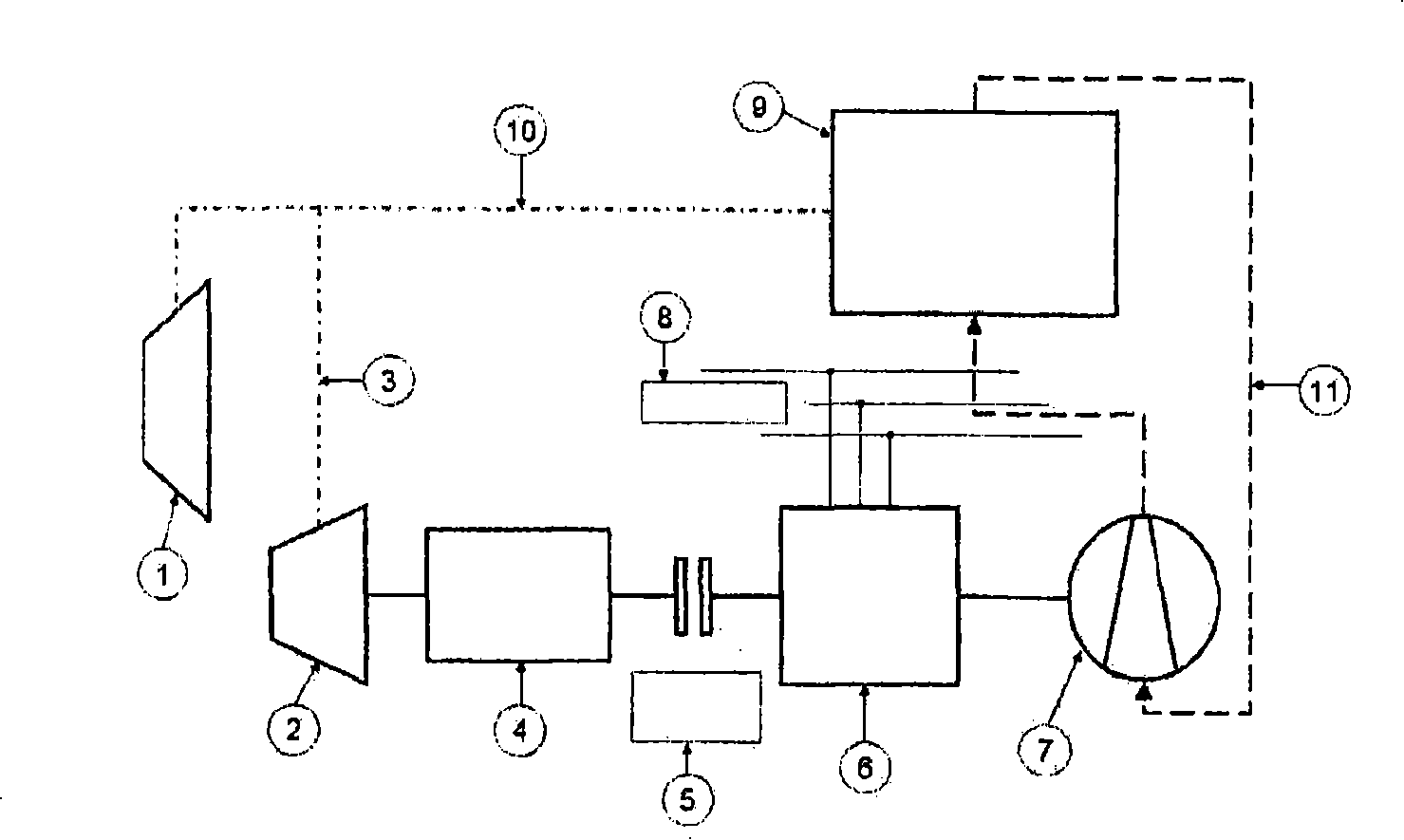

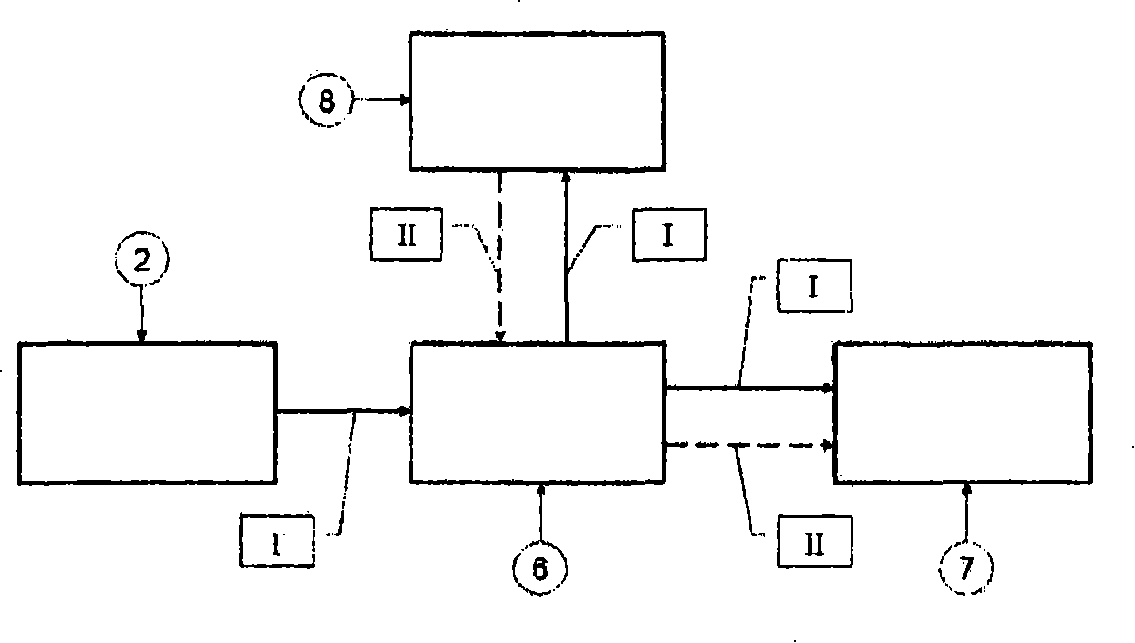

[0028] figure 1 Shown is a turbocharger 1 arranged in an exhaust gas line 10 of an internal combustion engine 9 , which serves to increase the specific power of the internal combustion engine 9 by supercharging. The power turbine 2 is arranged in the exhaust gas branch line 3 and is driven by exhaust gas energy which has not been utilized so far. The rotational movement of the power turbine 2 is transmitted to the actuating clutch 5 via a suitable transmission 4 via a mechanical connection.

[0029] On the other side, the actuating clutch 5 is mechanically coupled to the electric machine 6 . When the actuating clutch 5 is in the operating position, a mechanical force transmission from the actuating clutch 5 to the electric machine 6 takes place. In addition, the electric machine 6 is still connected to the ship's power grid, which is run trouble-free, for example by means of several standby generator sets, and which can deliver a constant-frequency current to the electric ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com