Vacuumization air exhausting device

An exhaust device and vacuum pumping technology, which is applied in the field of vacuum pumping systems, can solve the problems of small gaps, large heating energy consumption, and high air leakage rate of the interlayer, so as to achieve improved vacuum pumping efficiency, scientific structure design, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The best embodiment of the present invention will be described in further detail below with reference to the accompanying drawings.

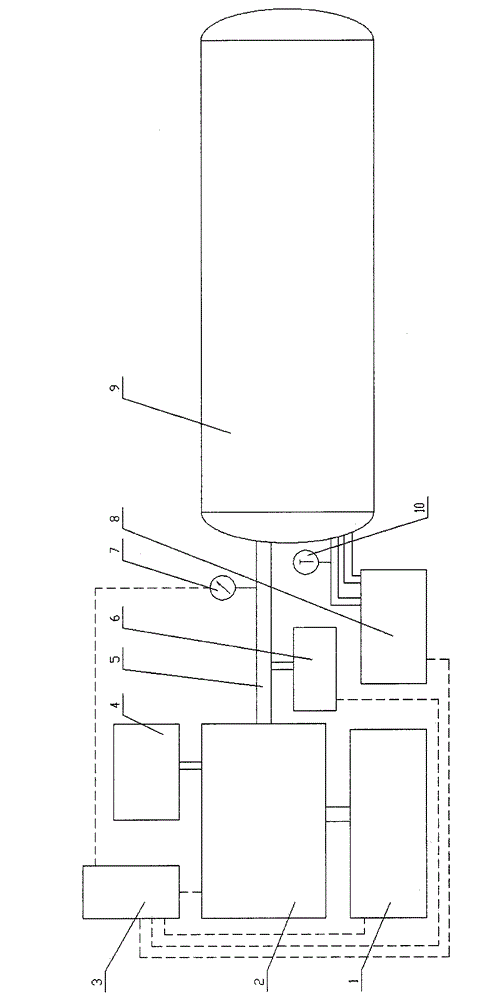

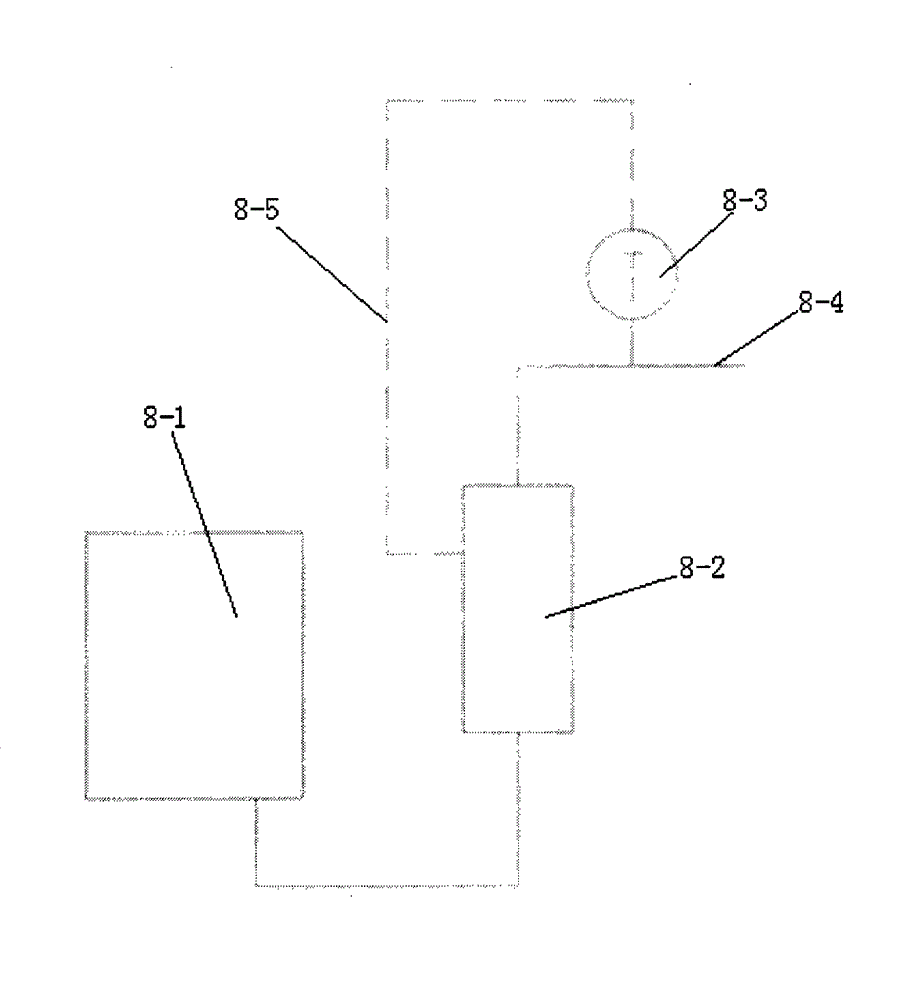

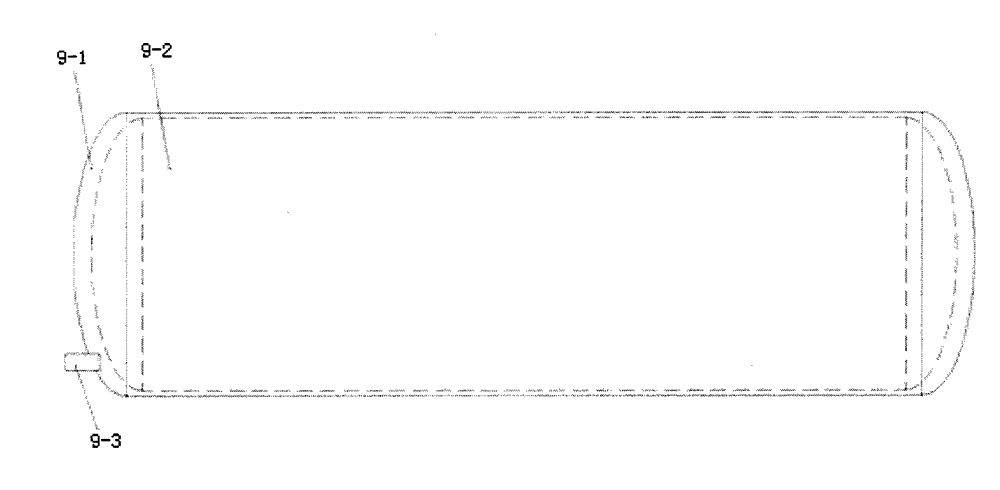

[0028] Such as figure 1 As shown, the vacuum exhaust device according to the embodiment of the present invention is used to vacuum the connected high-vacuum multi-layer insulation container, including the high-vacuum multi-layer insulation container 9, the rough extraction unit for obtaining vacuum 1, the fine extraction Unit 2, electric control system 3, heating device 8. The rough extraction unit 1 is connected to the fine extraction unit 2 through pipelines, and the fine extraction unit 2 is interlayer connected with the high-vacuum multi-layer insulation container 9 through the main pipeline 5. The vacuum multilayer insulation container 9 is connected to a heating device 8 through a pipeline. The heating device 8 is used for heating the interior of the high vacuum multilayer insulation container 9. After being heated by the heating system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com