Construction method for ultrahigh oblique post with super-large cross section based on integral lifting formwork reinforcing system

A formwork reinforcement and overall lifting technology, applied in formwork/formwork/work frame, processing of building materials, preparation of building components on site, etc., can solve the problems of complicated construction steps, high construction cost, slow construction process, etc. Achieve the effect of firm and reliable overall structure, improve construction efficiency and save construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The welding process, bolt connection construction process, winch construction process and concrete pouring construction process of this embodiment will not be repeated in this embodiment, and the embodiments of the present invention related to structures will be focused on.

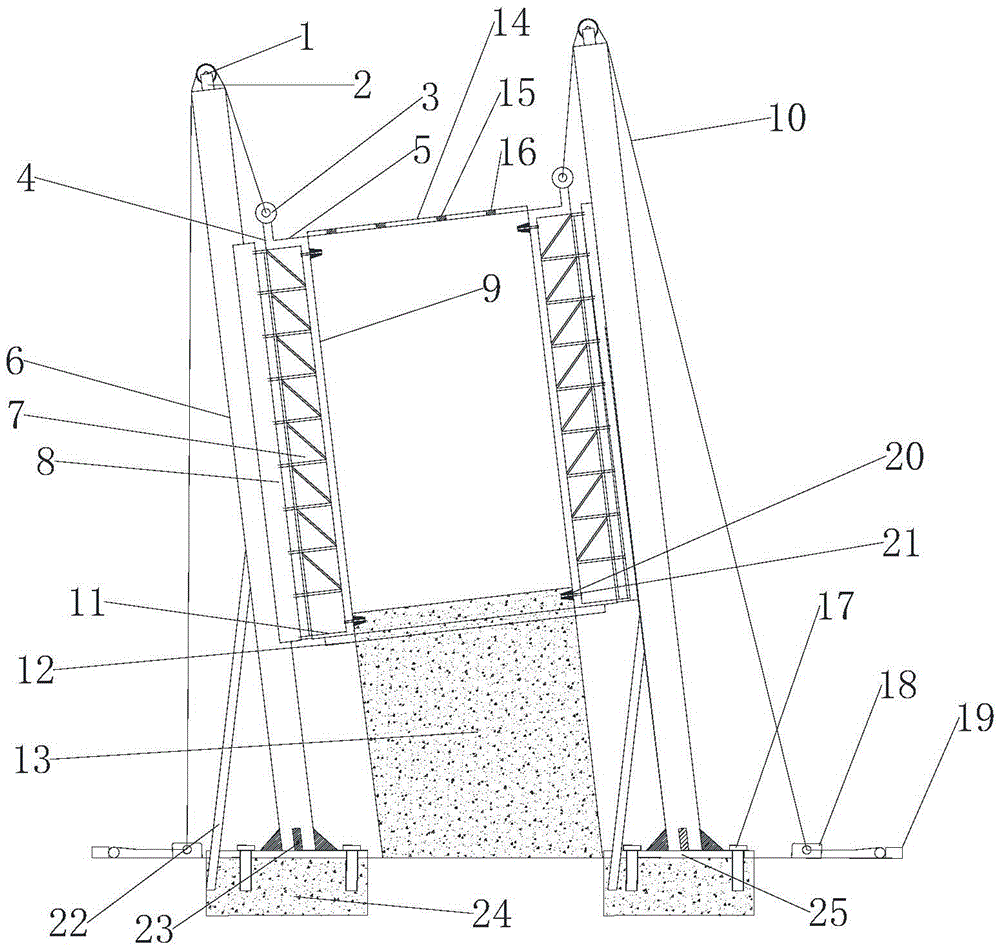

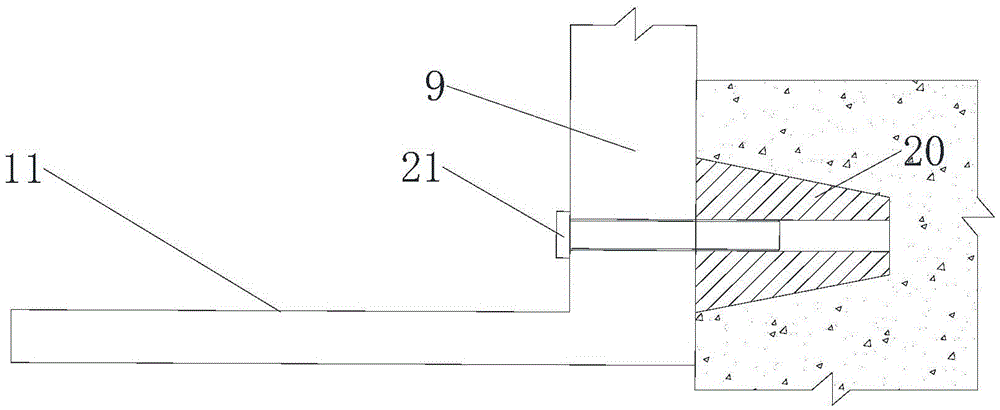

[0029] figure 1 It is a structural schematic diagram of the super-high super-large cross-section inclined column construction method based on the overall lifting formwork reinforcement system in this patent. refer to figure 1 As shown, the overall lifting formwork reinforcement system of this patent mainly includes: pulley 1, pulley base 2, suspension ring 3, upper platform pole 4, upper platform 5, inclined steel column 6, truss 7, guide rail 8, formwork 9, Steel wire rope 10, lower platform 11, pre-embedded steel pipe 12, poured concrete 13, cover plate 14, vibrating hole 15, vent hole 16, high-strength screw rod 17, ground cow 18, winch 19, pre-embedded bull nut 20, fixing screw rod 21, stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com