Aluminum surface ash removing agent and preparation method thereof, and surface ash removing method

A technology of ash removal agent and aluminum material, which is applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of inconspicuous ash removal effect, fast ash removal speed, and slow ash removal speed, and achieve improved ash removal The effect of ash speed, smooth surface effect, and obvious ash removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

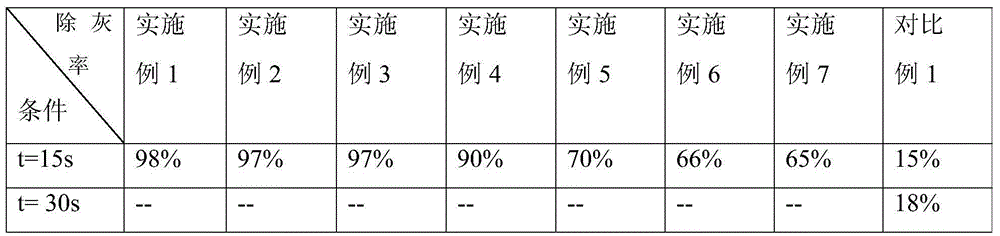

Examples

preparation example Construction

[0021] In a second aspect, the present invention provides a method for preparing an aluminum material surface dedusting agent, the method comprising: adding HNO 3 , NH 4 HF 2 , aluminum corrosion inhibitor and water are evenly mixed to obtain aluminum surface deashing agent, wherein, based on 1L aluminum surface deashing agent, HNO 3 The dosage is 540-720g, NH 4 HF 2 The dosage of aluminum corrosion inhibitor is 100-150g, the dosage of aluminum corrosion inhibitor is 1-8g, and the balance is water.

[0022] In order to improve the ash removal effect and ash removal speed of the prepared aluminum surface ash remover, preferably, in terms of 1L aluminum surface ash remover, HNO 3 The dosage is 585-675g, NH 4 HF 2 The dosage of aluminum corrosion inhibitor is 120-130g, the dosage of aluminum corrosion inhibitor is 2-4g, and the balance is water.

[0023] It should be understood by those skilled in the art that, in the preparation method of aluminum material surface dust re...

Embodiment 1

[0040] This embodiment is used to illustrate the aluminum material surface dust remover of the present invention and its preparation method.

[0041] Add 125g NH successively to the container 4 HF 2 , 685mL65vol% HNO 3 solution (d=1.40g / mL) and 100mL deionized water, stirred, and the NH 4 HF 2 After completely dissolving, add 3g of hexamethylenetetramine, continue to stir to completely dissolve the hexamethylenetetramine, and add the rest of deionized water to make the volume of the mixed solution 1L. After mixing evenly, you can get the aluminum material surface dust remover .

Embodiment 2

[0043] This embodiment is used to illustrate the aluminum material surface dust remover of the present invention and its preparation method.

[0044] Add 120g NH successively to the container 4 HF 2 , 643mL65vol% HNO 3 solution (d=1.40g / mL) and 100mL deionized water, stirred, and the NH 4 HF 2 After completely dissolving, add 2g of hexamethylenetetramine, continue to stir to completely dissolve the hexamethylenetetramine, and add the rest of deionized water to make the volume of the mixed solution 1L, and mix well to get the aluminum surface dust remover .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com