Light-color raw lacquer resin and preparation method thereof

A light-color, raw lacquer technology, applied in the field of raw lacquer, can solve the problems of deep color, difficult construction, and difficult toning, and achieve the effect of light color, easy spraying construction, and simple toning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

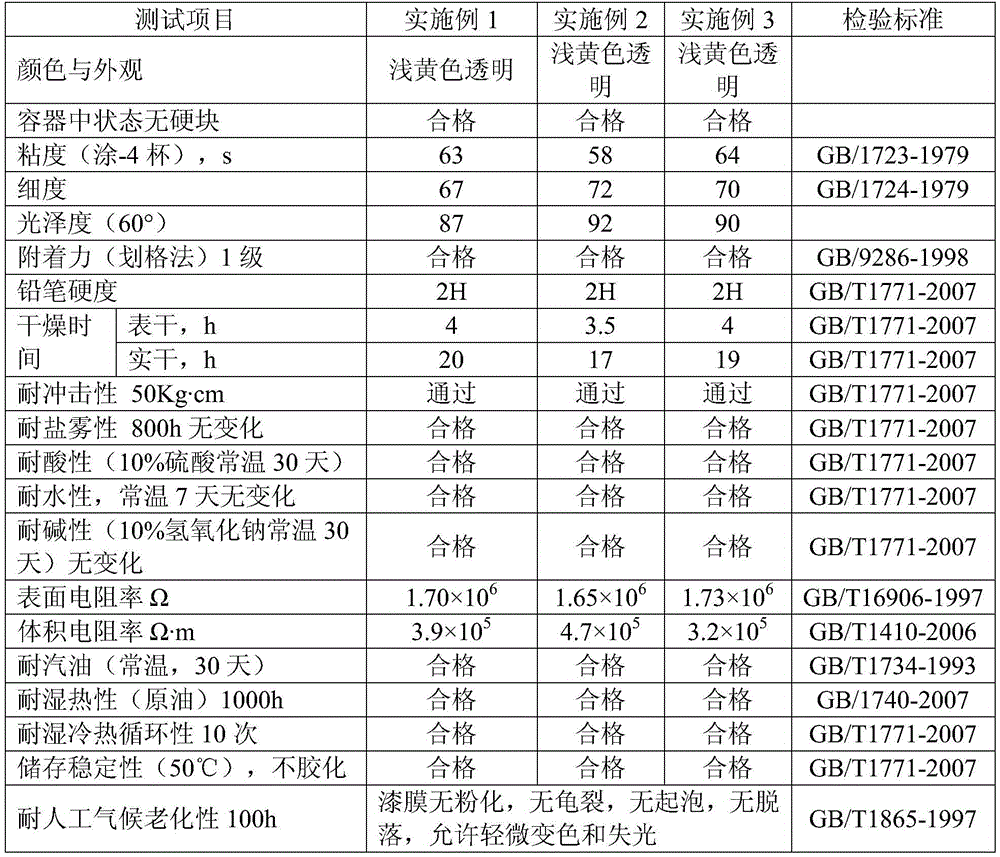

Examples

Embodiment 1

[0027] This embodiment provides a light-colored lacquer resin, which is prepared by polymerization of the following raw materials in parts by weight: 10% urushiol, 5% etherification reagent, 1% alkali catalyst, and 0.05% color reducing agent. %, vegetable oil is 12%, rosin is 10%, dibasic anhydride is 5%, and mineral spirits is 56.95%.

[0028] The etherification reagent is monochloroacetic acid; the alkali catalyst is sodium hydroxide; the color reducing agent is hypophosphorous acid; the vegetable oil is tung oil, which can also be replaced by catalpa oil; The acid anhydride is maleic anhydride; the solvent oil is No. 200 solvent oil, which can also be replaced by butyl acetate or cyclohexanone.

[0029] The raw lacquer light-colored resin in this example is prepared according to the above-mentioned raw material formula and synthesized through the following reaction, which specifically includes the following steps:

[0030] Step 1, mix raw lacquer with No. 200 solvent napht...

Embodiment 2

[0035] This embodiment provides a light-colored resin for raw lacquer, which is prepared by polymerization of the following raw materials in parts by weight: 18% urushiol, 7% etherification reagent, 1% alkali catalyst, and 0.04% color reducer %, vegetable oil is 10%, rosin is 8%, dibasic anhydride is 4%, and mineral spirits is 51.96%.

[0036] The etherification reagent is monochloropropionic acid; the alkali catalyst is lithium hydroxide; the color reducing agent is hypophosphorous acid; the vegetable oil is composed of tung oil and linseed oil in a mass ratio of 3:1 The mixed vegetable oil can also be replaced by a mixed vegetable oil composed of tung oil and catalpa oil in a mass ratio of 3:1; the dibasic acid anhydride is phthalic anhydride; the solvent oil is dimethyl carbonate.

[0037] The raw lacquer light-colored resin in this example is prepared according to the above-mentioned raw material formula and synthesized through the following reaction, which specifically in...

Embodiment 3

[0043] This embodiment provides a light-colored lacquer resin, which is prepared by polymerization of the following raw materials in parts by weight: 15% urushiol, 7% etherification reagent, 0.5% alkali catalyst, and 0.02% color reducing agent %, vegetable oil is 10%, rosin is 8%, dibasic anhydride is 2%, and mineral spirits is 57.48%.

[0044] The etherification reagent is ethyl chloroacetate; the alkali catalyst is lithium hydroxide; the color reducer is sodium phosphite; the vegetable oil is linseed oil, and tung oil, linseed oil and catalpa The oil is replaced by mixed vegetable oil with a mass ratio of 3:0.5:0.5; the dibasic acid anhydride is succinic anhydride; and the solvent oil is xylene.

[0045] The raw lacquer light-colored resin in this example is prepared according to the above-mentioned raw material formula and synthesized through the following reaction, which specifically includes the following steps:

[0046] Step 1, mix raw lacquer and xylene according to 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com