Method for Comprehensive Utilization of Domestic Garbage Incineration Power Generation Residue

A technology for domestic waste incineration and power generation residues, applied in cement production, sustainable waste treatment, solid waste management, etc., can solve problems such as inestimable economic value, expand comprehensive utilization channels, increase resource comprehensive utilization channels, protect environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

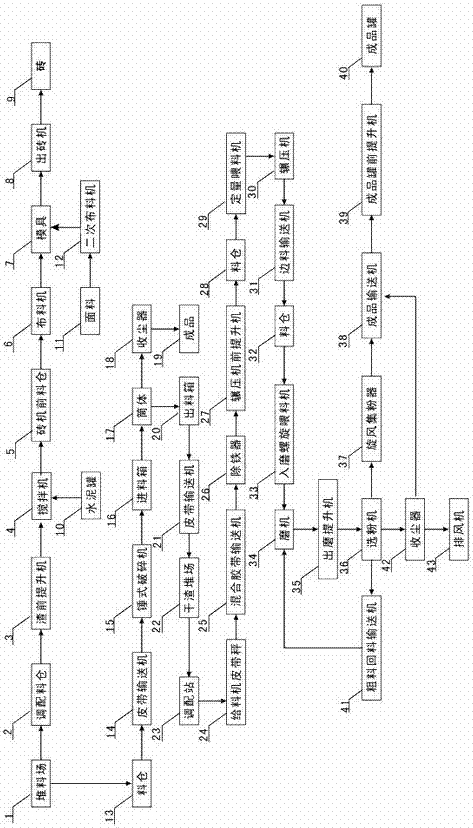

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] The residual residue of domestic waste incineration and power generation enters the sand collection tank through rolling screening, magnetic separation, flotation, and selection. The specific process is: Rolling screening: Put the residue of domestic waste incineration and power generation into the rolling screen to remove large pieces of scrap iron such as iron wire and iron sheet, as well as unburned large domestic waste, and the finer residue falls into the silo under the rolling screen; Magnetic separation: The finer residue from the silo enters the first crusher through the conveyor belt, and an iron remover is installed in the middle of the conveyor belt before entering the first crusher for magnetic separation to remove the scrap iron in the finer residue ; Flotation: The residues and scraps from the first crusher enter the jig for flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com