Automatic marine telescopic accommodation ladder

An automatic retractable and gangway technology, which is applied in the direction of ship accessories, ships, cargo handling equipment, etc., can solve the problems of large moving range, dangerous walking of personnel, and inability to independently expand and contract, so as to achieve the effect of free expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

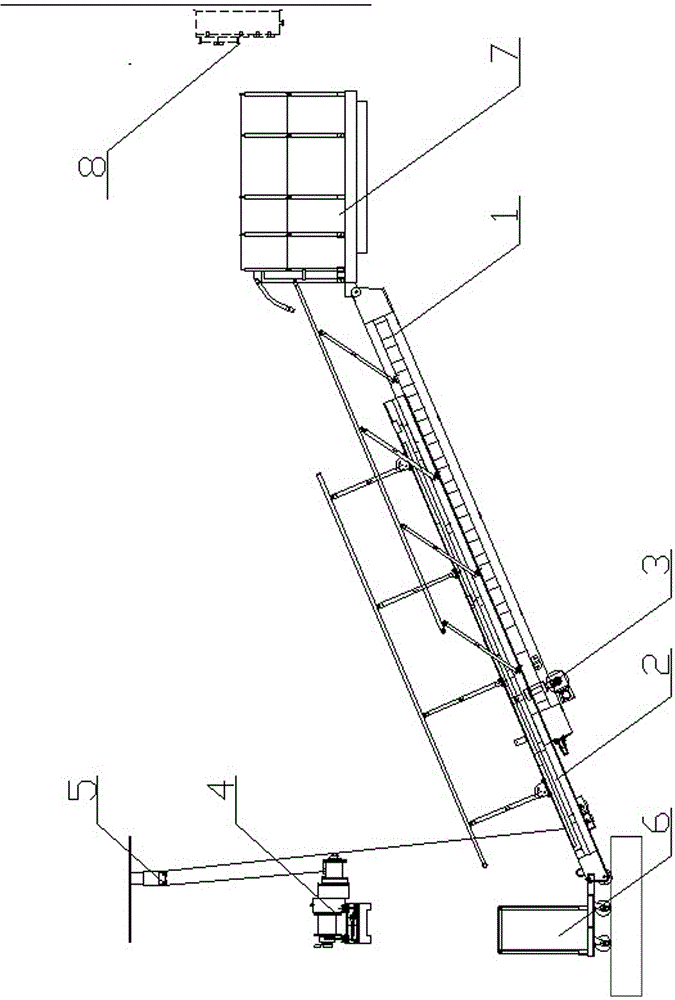

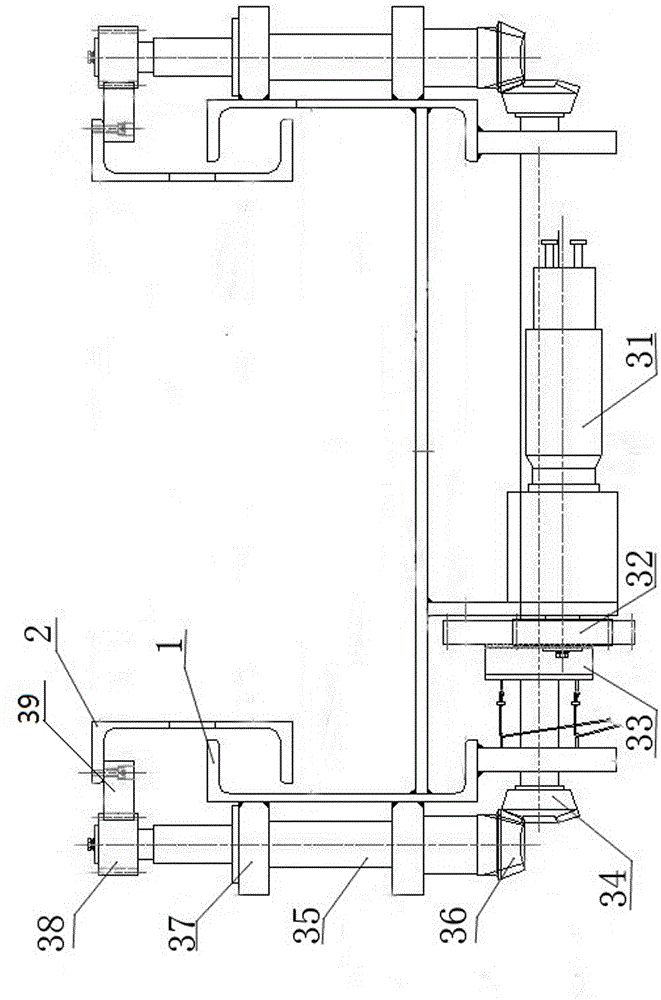

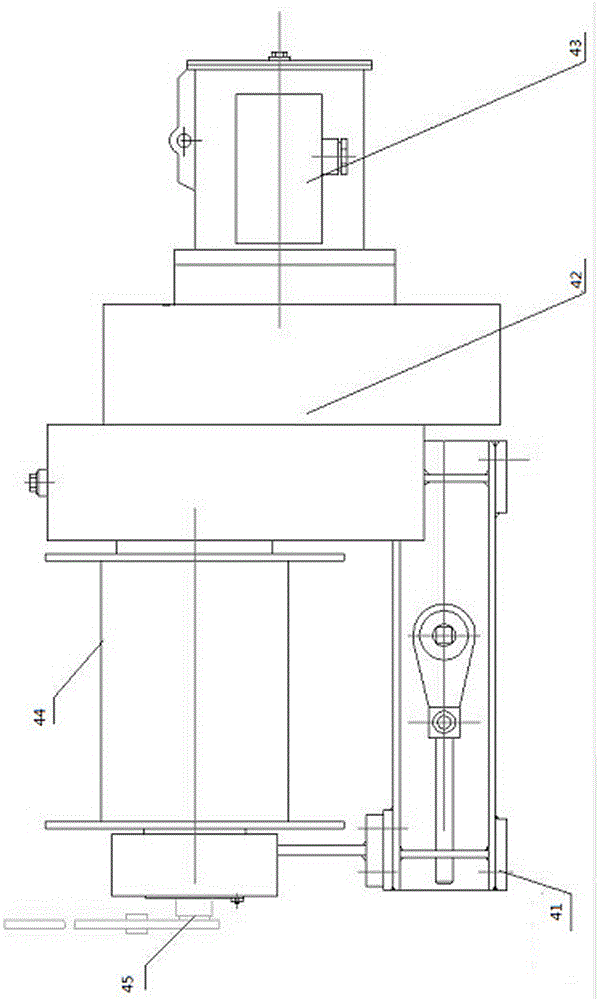

[0019] As shown in the figure, an automatic telescopic gangway for ships includes a secondary gangway, a telescopic drive device 3, a hoisting winch 4 and a control system. The second gangway includes an upper gangway 1 and a lower gangway 2. The pin is hinged on the upper platform 7 of the hull, and the upper gangway 1 and the lower gangway 2 are connected by sliding rails. The telescopic driving device is installed between the upper and lower gangway. The telescopic driving device includes a servo motor 31 installed on the upper gangway 1, a horizontal The bevel gear shaft 34, two vertical shafts 35 and the racks 39 installed on both sides of the upper gangway, the servo motor 31 and the horizontal bevel gear shaft 34 are connected through a reduction mechanism 32 above one level, and the bevel gear shaft 34 is equipped with Friction clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com