Light-weight die for high-precision large-sized antenna for radio astronomy and manufacturing method thereof

A high-precision, lightweight technology, applied in the field of lightweight molds and their manufacturing, can solve problems such as variation and overweight precision, and achieve the effects of reducing mold weight, ensuring overall rigidity, and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

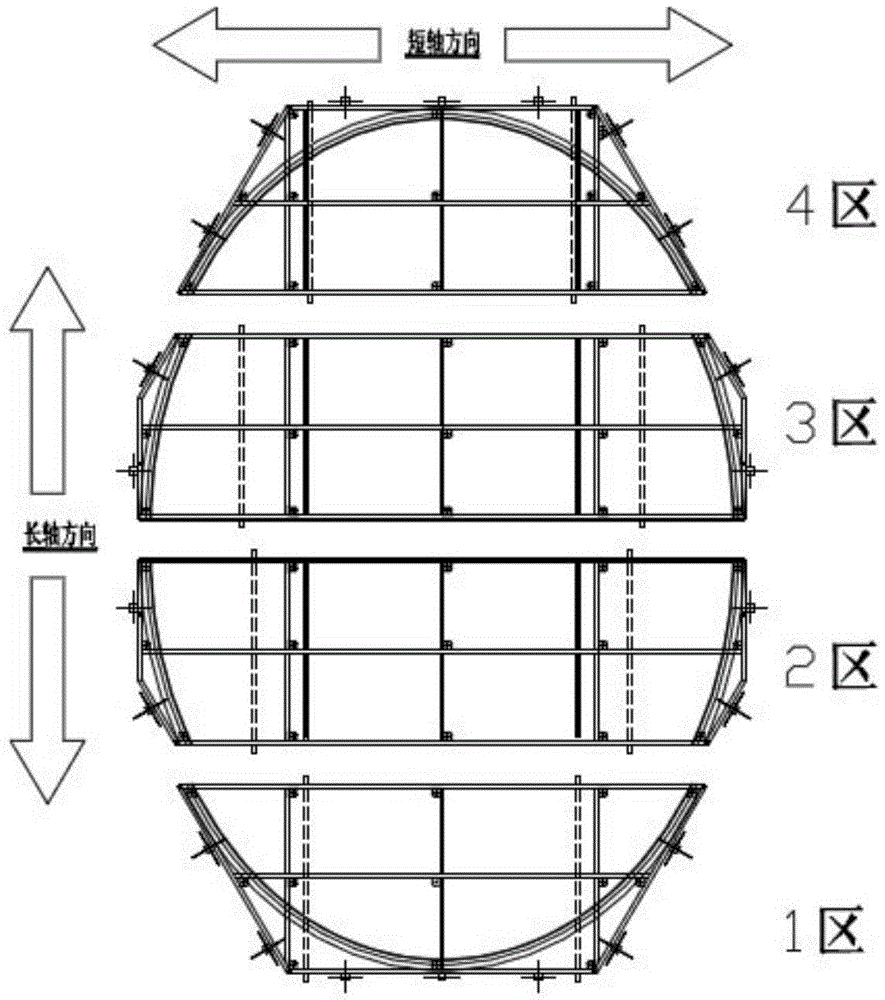

[0027] Below, combine Figure 1-Figure 3 , the present invention will be further described.

[0028] A lightweight mold for a high-precision large-scale radio antenna, which is composed of multiple mold units spliced together, is characterized in that: the mold unit includes a mold surface 1 and a rigid structure 2 for supporting the mold surface, and the rigid structure 2 includes A steel frame 4 and a plurality of steel partitions 3, the plurality of steel partitions 3 are vertically fixed on the upper surface of the steel frame 4 and the upper surfaces of the plurality of steel partitions 3 match the contour of the corresponding mold surface 1.

[0029] Wherein, the mold profile 1 includes a profile square tube layer 5, a glass fiber reinforced plastic layer 6, and a resin layer 7 arranged sequentially from bottom to top; the profile square tube layer 5 is composed of a plurality of closely tiled square tubes successively, and the profile The lower surface of the square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com