Laser soldering device and welding method

A soldering and laser technology, used in welding equipment, electric heating devices, manufacturing tools, etc., can solve the problems of laser soldering application limitations, low wire feeding soldering work efficiency, uneven heating of solder paste, etc. Work efficiency and stability, solid solder joints, and the effect of avoiding uneven heat spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

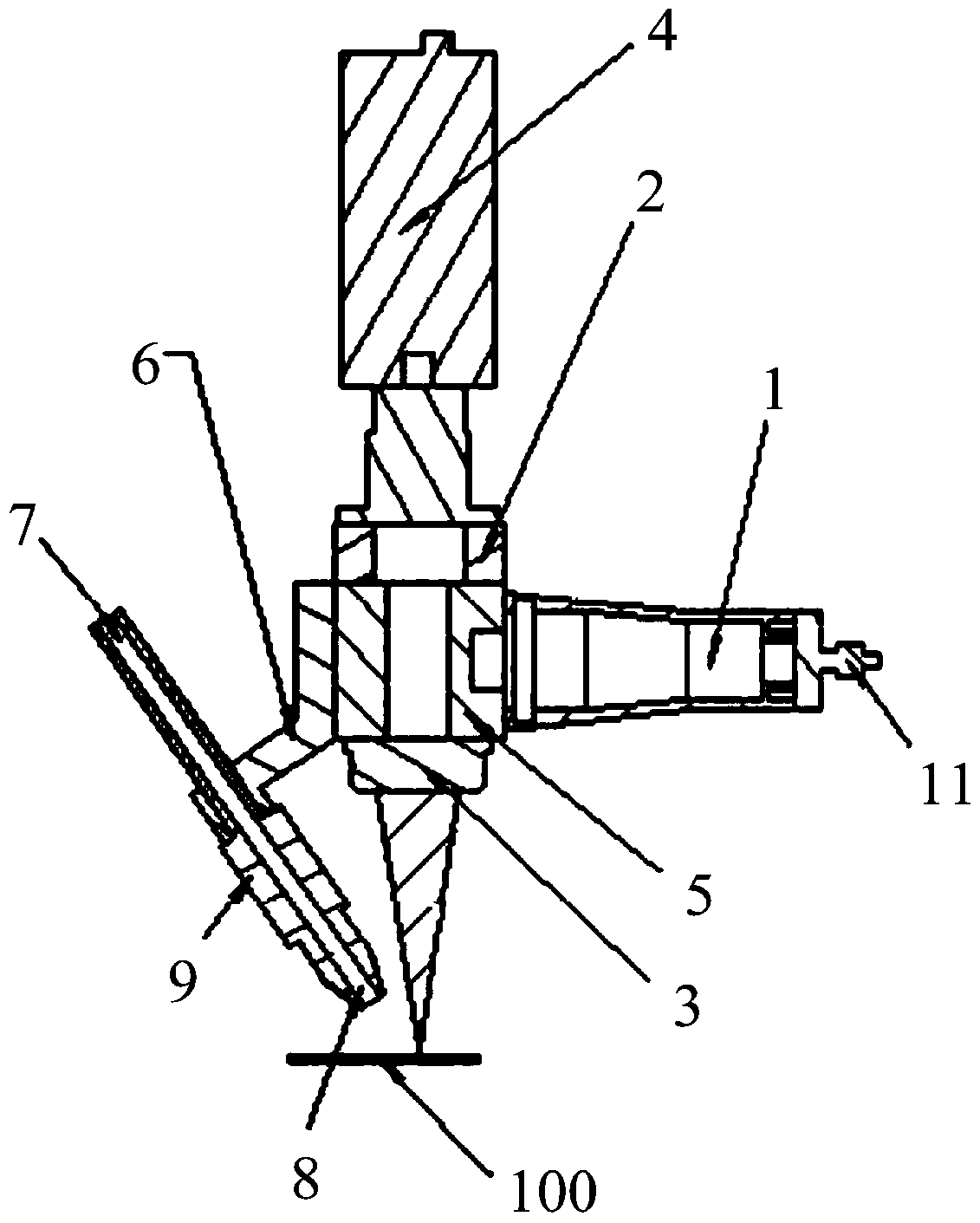

[0019] see figure 1 , a laser soldering device of the present invention, including a fixture (not shown) for clamping a workpiece 100 to be welded, a laser (not shown), a collimating head 1 connected to the laser, and a CCD adjustment mirror seat 2 and focusing head 3, one end of the collimating head 1 is connected to the laser through an optical fiber (not shown), and the other end is connected to the CCD adjusting mirror base 2, and the top of the CCD adjusting mirror base 2 is provided with a CCD lens 4, so The bottom end of the CCD adjusting mirror base 2 is connected to the focusing head 3, and the CCD adjusting mirror base 2 is connected with a relatively rotatable hot air blowing assembly.

[0020] Wherein, the hot air blowing assembly includes a connecting head 5 sleeved on the CCD adjustment mirror base 2, a clamping seat 6 and a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com