On-line control method for removing foreign matters adhered to the roll surface

A control method and technology for foreign matter, applied in cleaning methods and appliances, rolling mill control devices, chemical instruments and methods, etc., can solve the problem of foreign matter falling on the surface of strip steel, high investment and maintenance costs, tension roller indentation, etc. problems, to achieve the effect of eliminating strip cuts, reducing risks, and avoiding gaps

Active Publication Date: 2018-04-24

SHANGHAI MEISHAN IRON & STEEL CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

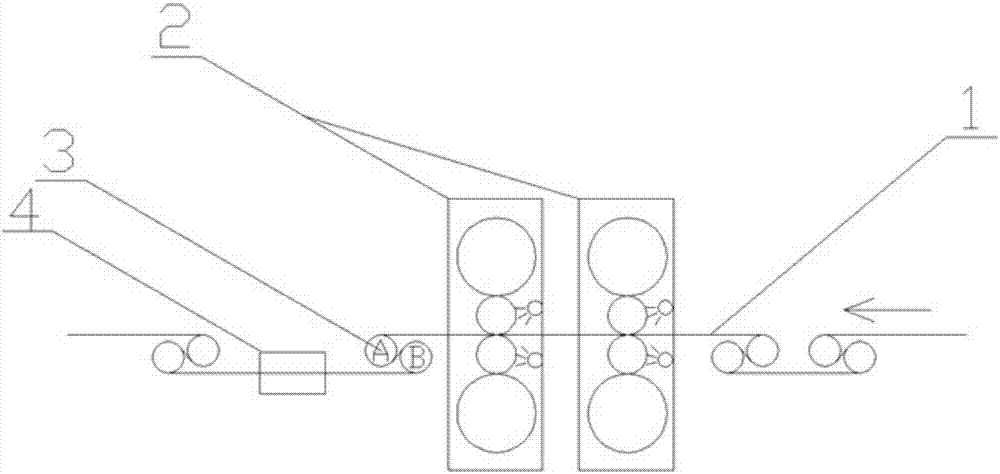

[0002]In modern cold-rolling continuous annealing or coating units, product quality problems have always been the focus and difficulty of the unit operators. During the roll change process of the temper mill, the indentation of the tension roller is caused by the falling of foreign objects in the frame. The foreign objects are generally particles formed by the accumulation of rolling dust in the frame of the temper mill. During the rolling or roll change process , due to the vibration of the frame, the foreign matter in the frame falls, adheres to the surface of the strip steel, and transfers to the roller surface with the help of the strip steel

[0003] The patent CN 2757952 Y tension roller cleaning device was retrieved. The main problem to be solved by this disclosed technology is similar to this technology, but the equipment investment and maintenance costs of the tension roller cleaning device described in this disclosed technology are high, and it needs to be installed in each This device is installed on the rollers. At the same time, after using this device to grind the roller surface, foreign matter may fall on the surface of the strip again, which will cause secondary pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

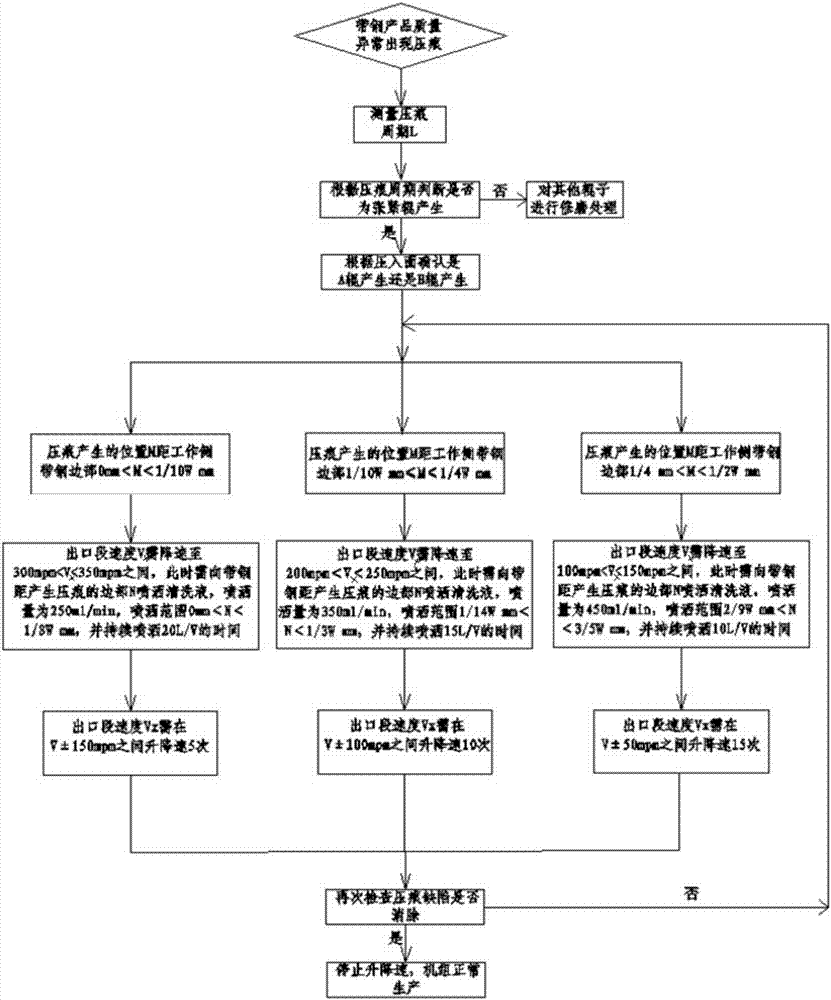

[0043]When the position M of the indentation is 0mm

Embodiment 2

[0045] When the position M where the indentation occurs is 90mm≤M≤225mm from the edge of the strip steel on the working side, the speed Vx at the exit section of the unit is reduced to 220mpm. The spraying volume is 350ml / min, the spraying range is 64mm

Embodiment 3

[0047] When the position M where the indentation occurs is 225mm

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

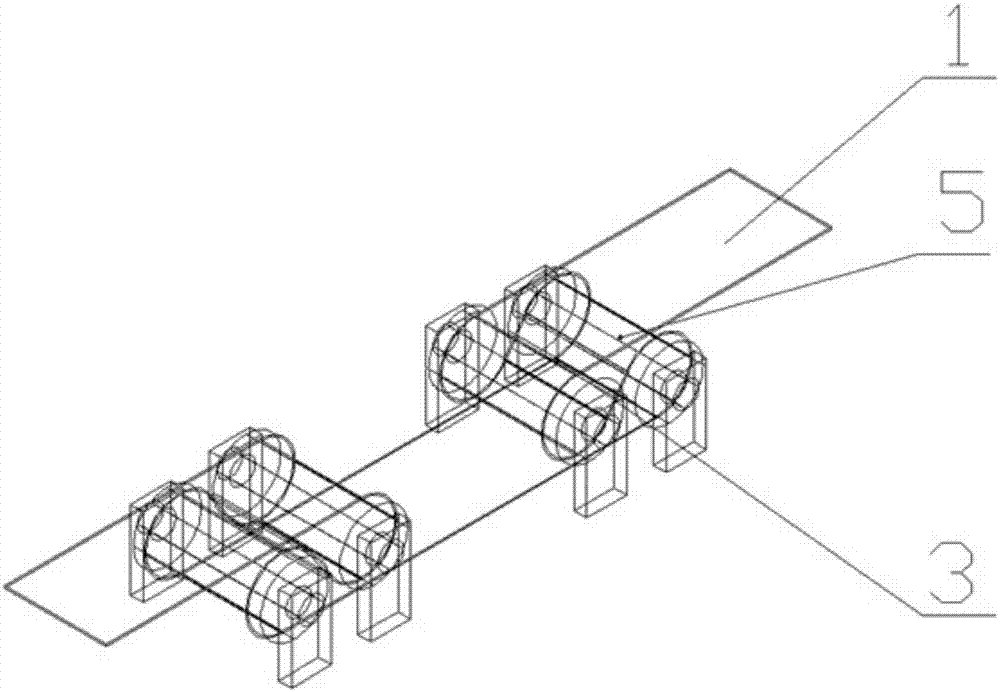

The invention provides a control method for removing foreign matter adhered to a roll surface on-line. The method of the present invention includes the following steps: (1) determine the specific tension roller that produces the indentation by sampling the defective sample, (2) spray cleaning liquid according to the position of the indentation and the width of the strip steel, (3) According to the spraying range, spraying amount and unit speed V of the cleaning liquid, different speed changes are used to perform different times of speed up and down operations to further improve the effect of repeated grinding of foreign objects; (4) Hot air drying. The present invention achieves the purpose of on-line removal of foreign matters adhered to tension rollers under the condition of utilizing existing equipment and without affecting the operation of the unit.

Description

Technical field: [0001] The invention relates to a control method for on-line removal of adhering foreign matter on a roll surface, and belongs to the technical field of cold rolling process control. Background technique: [0002] In the modern continuous annealing or coating line of cold rolling, the product quality problem has always been the focus and difficulty to be overcome by the operators of the unit. What has always troubled the operators in the work is that the foreign matter in the frame fell during the roll change process of the skin pass mill. The problem of indentation of the tension roller is caused. The foreign matter is generally the particles formed by the accumulation of rolling dust in the frame of the skin pass mill. During the rolling or roll changing process, the foreign matter in the frame will fall due to the vibration of the frame Attached to the surface of the strip steel and transferred to the roller surface by means of the strip steel. Since the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B28/00B21B37/00B08B7/04

Inventor 李少朋王金华徐烨明马卫

Owner SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com