Stripper unit and hydraulic working apparatus having a stripper unit

A technology of operating equipment and scrapers, applied in the field of hydraulic cylinders and hydraulic operating equipment, can solve the problem that the scraper unit no longer performs cleaning and/or protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

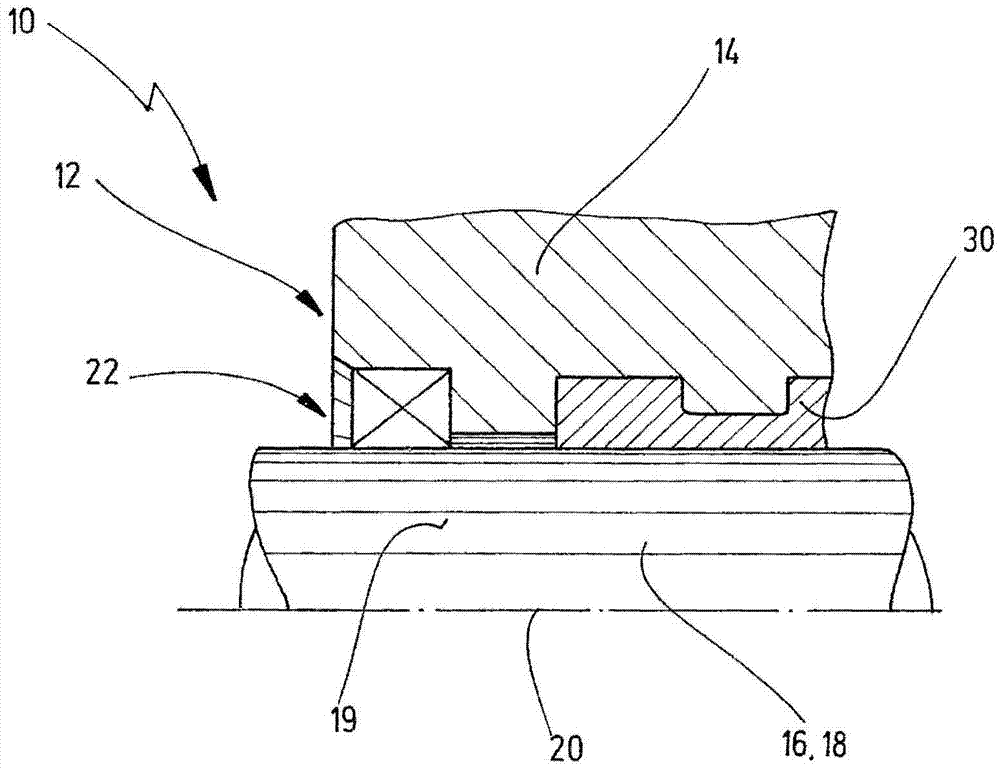

[0036] figure 1 A partial side view of a hydraulic working device 10 is shown, which can be designed, for example, as a hydraulic cylinder. The hydraulic working device 10 has a housing-fixed part or housing part 14 which surrounds a sliding counterpart 16 . Sliding counterpart 16 is designed here, for example, as piston rod 18 (in figure 1 are only partially shown). The sliding counterpart 16 has a substantially rotationally symmetrical, in particular cylindrical, sliding surface 19 . The sliding counterpart 16 also has a longitudinal axis 20 which can coincide with a corresponding longitudinal axis passing through the housing part 14 . The hydraulic working device 10 can be designed to generate a relative movement, in particular a sliding movement along the longitudinal axis 20 , between the housing part 14 and the sliding counterpart 16 . In this case, it is initially irrelevant which of the two parts 14 , 16 performs the absolute movement.

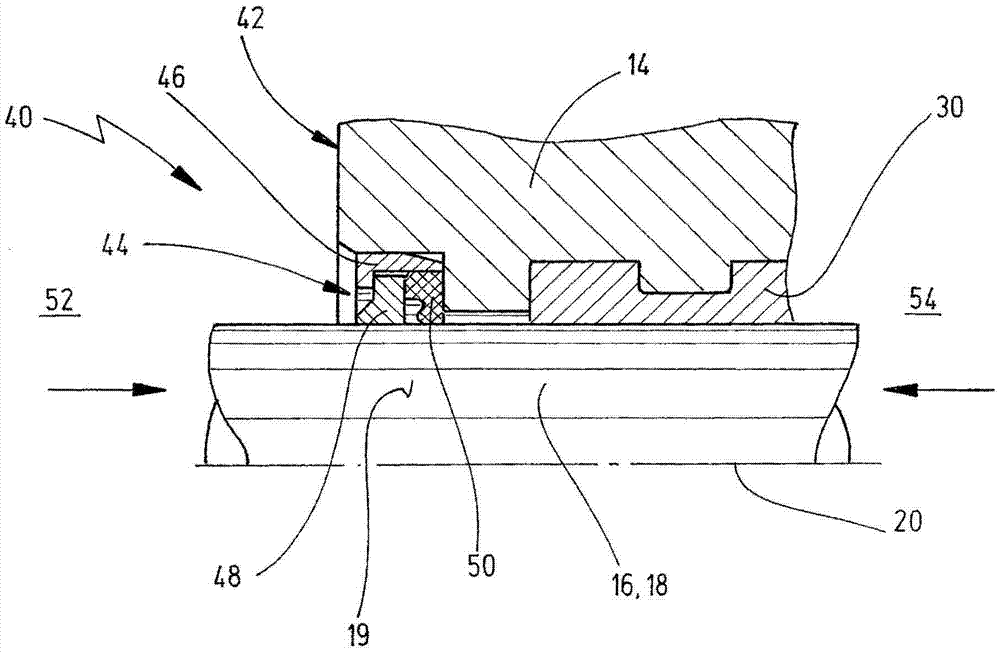

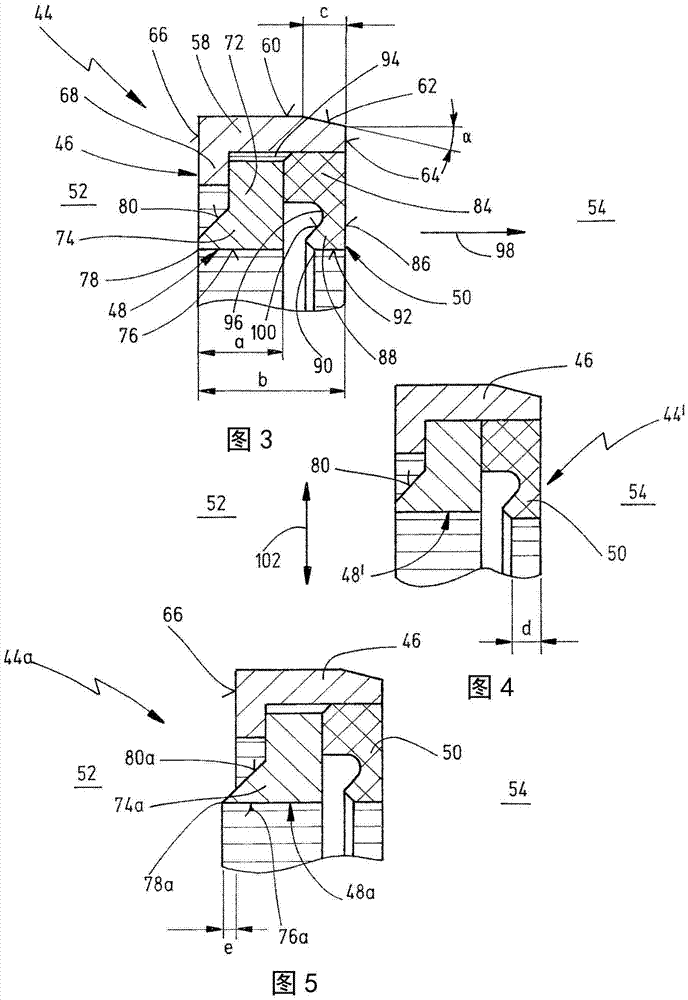

[0037] The hydraulic worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com