Adhesive composition and composite polarizing plate using same

A composition and adhesive technology, applied in the direction of film/sheet adhesive, other plywood/plywood appliances, non-polymer organic compound adhesive, etc., can solve the degradation, peeling or bulging of 3D three-dimensional effect , Polarizer peeling and other problems, to achieve excellent heat resistance and heat and humidity resistance, with polarization performance, the effect of suppressing peeling and bulging phenomenon

Inactive Publication Date: 2016-03-30

DONGWOO FINE CHEM CO LTD

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] When the adhesion between such a patterned retardation film and the polarizing plate or polarizer decreases, deformation may occur during handling during manufacturing or use

Also, there may be concerns about peeling or swelling when exposed to heat and humidity for extended periods of time

In addition, typical PVA polarizers can shrink in the pulling direction, thus involving different retardation at different positions of the retardation film, which in turn leads to the degradation of the 3D stereoscopic effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0175] Examples and Comparative Examples

[0176] Adhesive compositions were prepared with various constituents and levels listed in Table 1 below.

[0177] [Table 1]

[0178]

[0179]

[0180]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

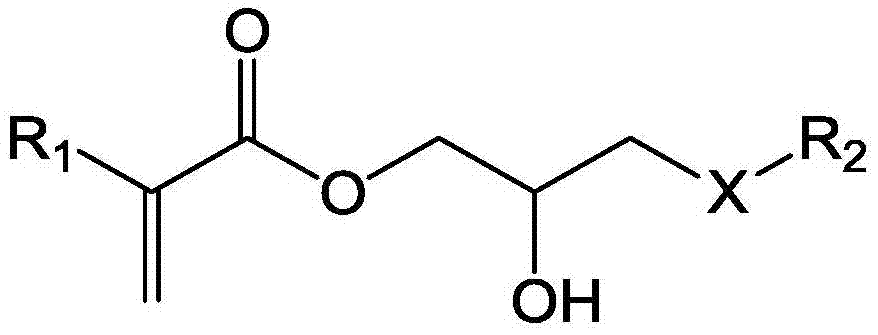

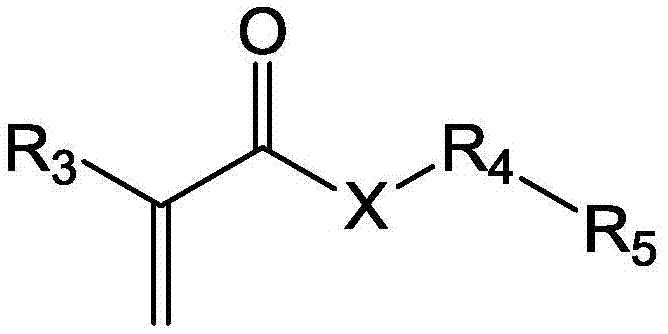

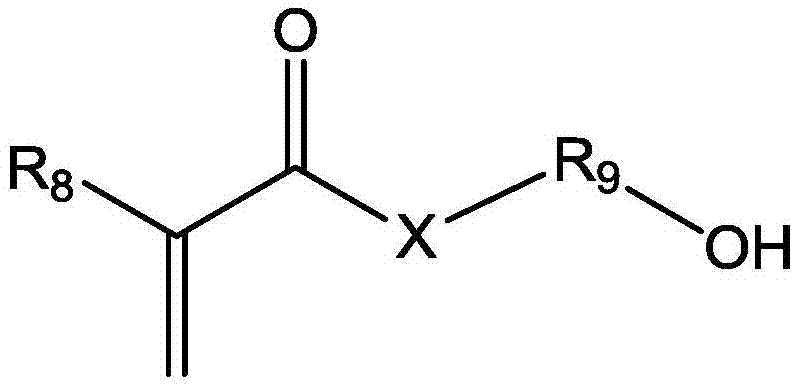

The present invention relates to an adhesive composition and a composite polarizing plate using same, more specifically to an adhesive composition and a composite polarizing plate using same, in which the adhesive composition comprises: a photopolymerizable compound containing acrylic monomers having a hydroxyl or carboxyl group, and 6-18 carbon aromatic rings; and a photopolymerization initiator, thereby markedly improving the adhesiveness between a polarizer and a patterned retardation layer when utilized in producing a composite polarizing plate by adhering the polarizer and patterned retardation layer, and contributing to improving heat resistance and moist heat resistance, as well as to imparting a superb three-dimensional effect.

Description

technical field [0001] The present invention relates to an adhesive composition and a composite polarizing plate using the same. Background technique [0002] In general, a display device for obtaining a stereoscopic image, such as a liquid crystal display device, often includes a patterned retardation film. This patterned retardation film has a technical configuration in which the optical axes of the separated pattern regions are formed in directions different from each other to transmit the separated images to the left and right eyes of the viewer wearing polarized glasses, thereby embodying three-dimensionality (ie, stereoscopic) images. [0003] The patterned retardation film is generally prepared by forming an alignment layer on a glass substrate and applying liquid crystal to the alignment film to obtain alignment properties. A photosensitive liquid crystal material is aligned on the alignment layer and then crosslinked by light radiation, such as ultraviolet light, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J4/02C09J7/02G02B5/30

CPCB27M1/04B27D5/00B25D1/00

Inventor 崔汉永金容演郑宥利

Owner DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com