Preparation method of cylindrical battery free of tab welding

A tab welding and cylindrical technology, which is applied in the preparation field of cylindrical battery without tab welding, can solve the problems of poor welding effect, loss of space capacity, high internal resistance of the battery, etc., so as to improve energy density and use safety, and reduce labor costs. Step, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] An embodiment of the present invention provides a preparation method for welding a cylindrical battery without tabs, including the following steps:

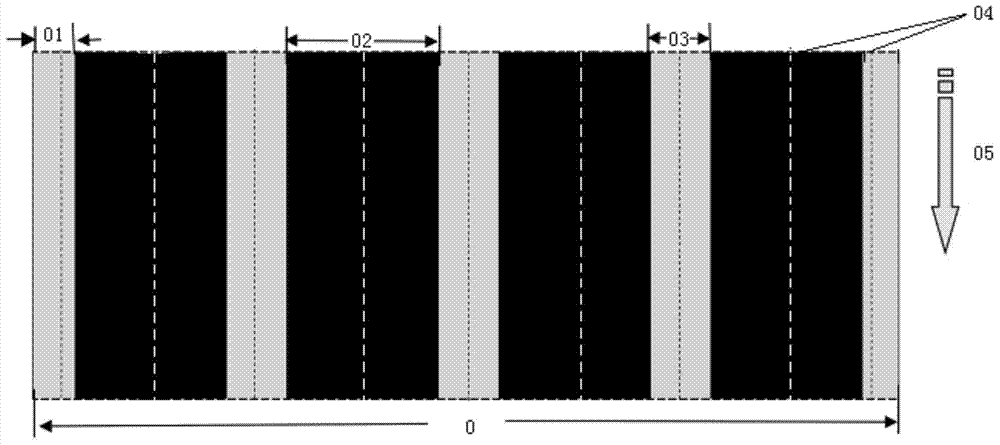

[0019] S01. The positive and negative electrode substrates are longitudinally intermittently coated, and after cutting, the positive and negative electrodes with blank spaces on one side are obtained respectively;

[0020] S02. Laminate the positive electrode sheet, diaphragm, and negative electrode sheet in sequence, and then wind them into a core, and place the ends of the positive and negative electrode sheets with blank space on the outer sides of the two long sides of the separator, and the edge of the separator is exposed. There is blank space;

[0021] S03. Flatten the exposed blank foil to form a flat and smooth positive and negative foil table;

[0022] S04. Use a negative electrode collector with a boss to pressure-place it on the negative electrode foil table of the core, and perform laser welding to form a neg...

Embodiment 1

[0045] A preparation method for welding a cylindrical battery without tabs, comprising the following steps:

[0046] S11. Apply longitudinal intermittent coating to the base material of the positive and negative electrodes, and after cutting, respectively obtain the positive and negative electrodes with blank spaces on one side;

[0047] S12. Laminate the positive electrode sheet, the diaphragm, and the negative electrode sheet in sequence, and then wind them into a core, and place the ends of the positive and negative electrode sheets with blank space on the outer sides of the two long sides of the diaphragm, and the edge of the diaphragm is exposed. There is blank space;

[0048] S13. Flatten the exposed blank foil to form a flat and smooth positive and negative foil table;

[0049] S14. The negative electrode uses a circular Ni sheet with a boss in the center, the specification is Φ16*0.1mm, and the boss is placed on the Cu foil table of the negative electrode for laser we...

Embodiment 2

[0051] A preparation method for welding a cylindrical battery without tabs, comprising the following steps:

[0052] S11. Apply longitudinal intermittent coating to the base material of the positive and negative electrodes, and after cutting, respectively obtain the positive and negative electrodes with blank spaces on one side;

[0053] S12. Laminate the positive electrode sheet, the diaphragm, and the negative electrode sheet in sequence, and then wind them into a core, and place the ends of the positive and negative electrode sheets with blank space on the outer sides of the two long sides of the diaphragm, and the edge of the diaphragm is exposed. There is blank space;

[0054] S13. Flatten the exposed blank foil to form a flat and smooth positive and negative foil table;

[0055] S14. The negative electrode uses a circular Ni sheet with a boss in the center, the specification is Φ16*0.1mm, and the boss is placed on the Cu foil table of the negative electrode for laser we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com