Substrate processing apparatus and substrate processing method

A technology for a substrate processing apparatus and a substrate processing method, which are applied in the directions of cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc., can solve the problems of etching residues, large etching residues, and etching liquid 351 without stirring. , to achieve the effect of preventing the fluctuation of the processing rate and suppressing the fluctuation of the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, embodiments of the present invention will be described based on the drawings. In the drawings, parts having the same structure and function are given the same reference numerals, and repeated descriptions will be omitted in the following description. In addition, each drawing is schematically shown. In addition, in the description of the embodiment, the vertical direction is the vertical direction, the substrate W side is the upper side, and the spin chuck 111 side is the lower side.

[0056]

[0057]

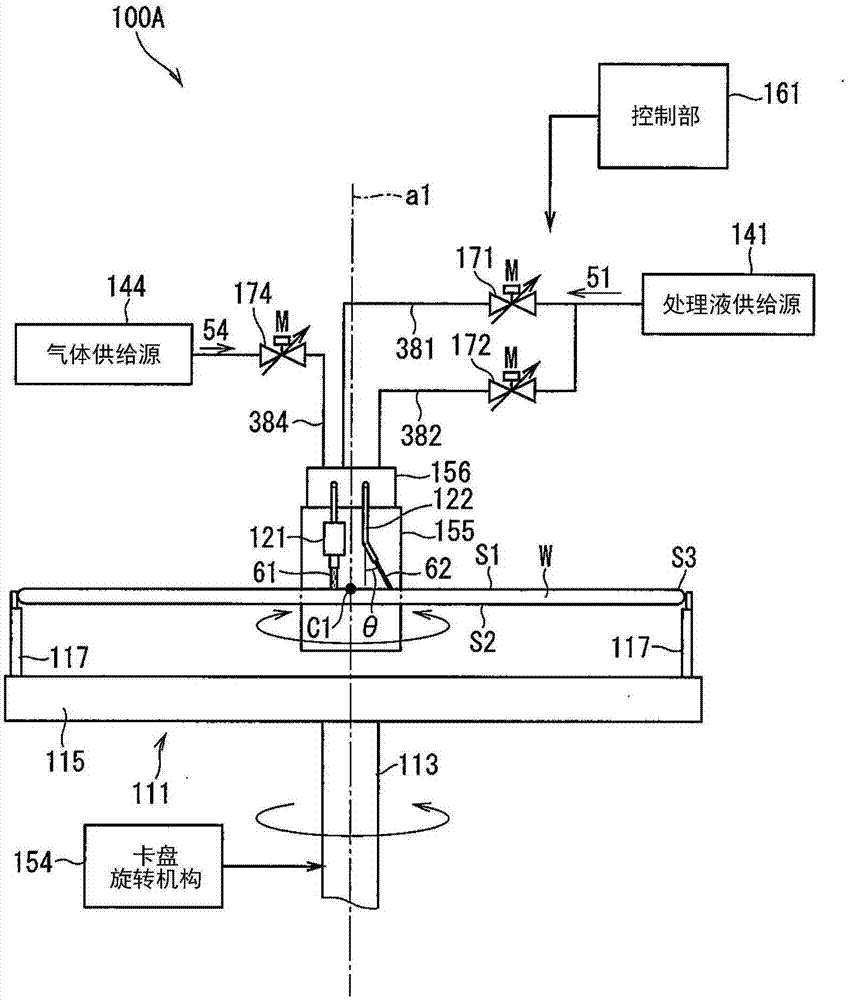

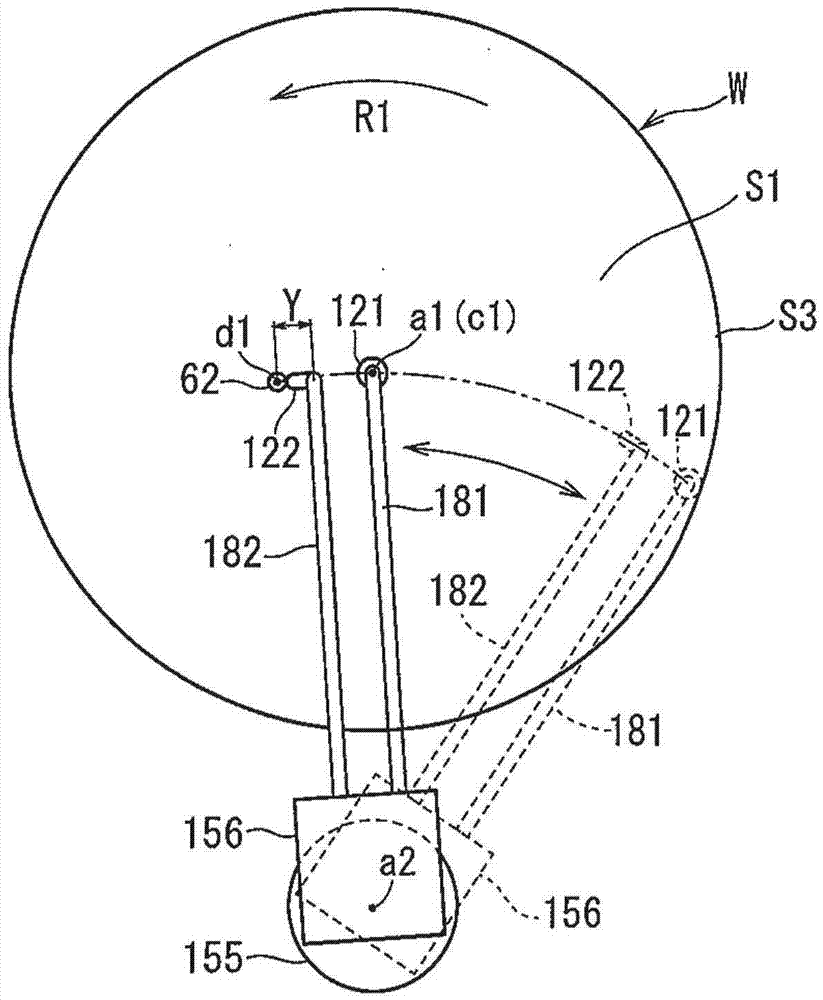

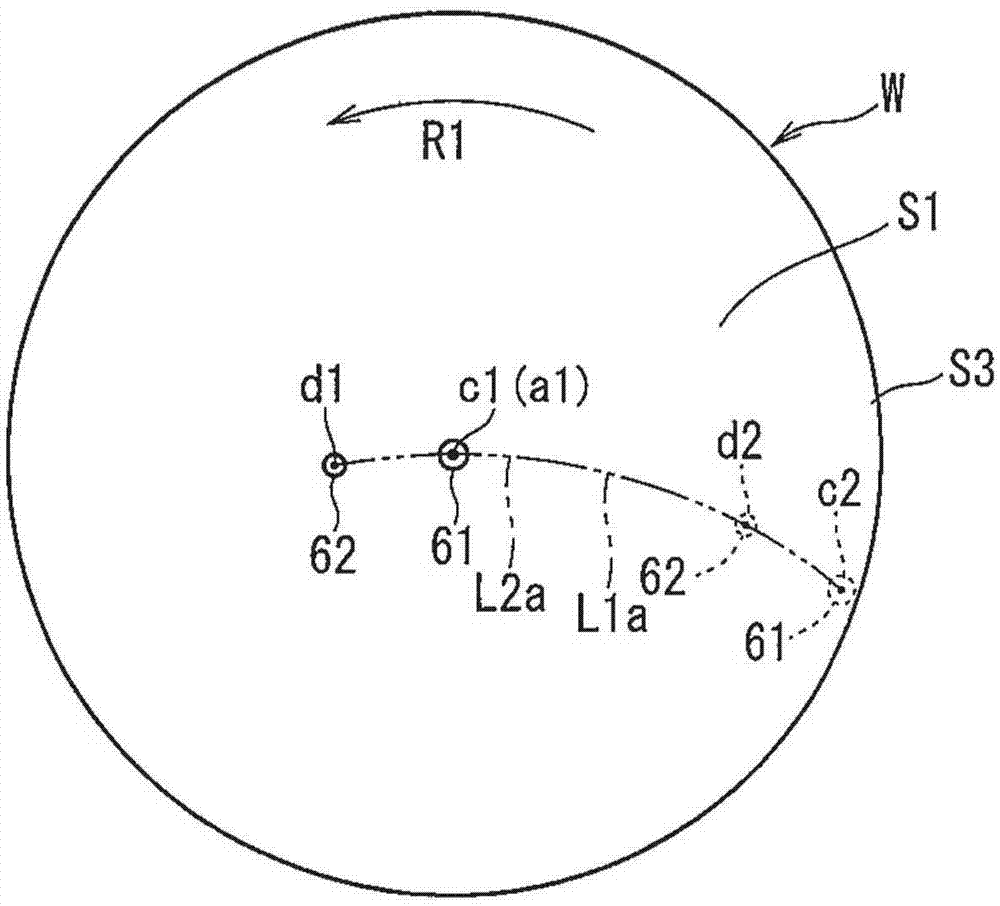

[0058] figure 1 It is a figure which schematically shows an example of the schematic structure of 100 A of substrate processing apparatuses concerning embodiment. figure 2 It is a figure which looked at the two nozzles 121 and 122 of the substrate processing apparatus 100A from above the board|substrate W.

[0059] The substrate processing apparatus 100A processes a substrate using a processing liquid. Specifically, for example, the substrate proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com