Car body electric control system testing platform based on hardware-in-the-loop

An electronic control system and test platform technology, applied in the direction of electrical testing/monitoring, can solve the problems of difficulty in simulating extreme working conditions or dynamic working conditions, inability to perform integrated testing, and high tester dependence, so as to reduce labor consumption and shorten the Development cycle, effects of extended testing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

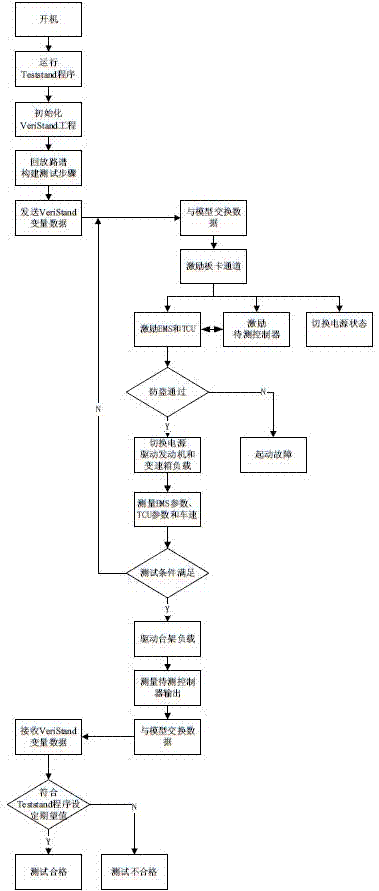

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

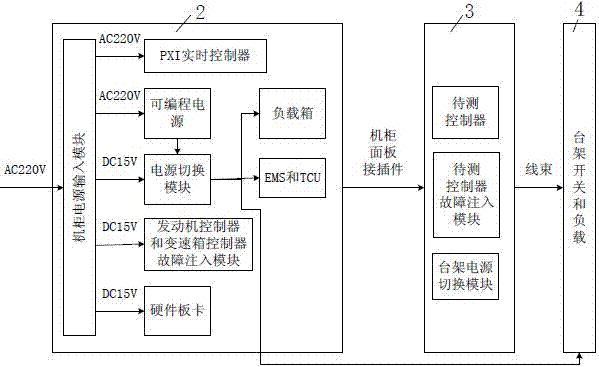

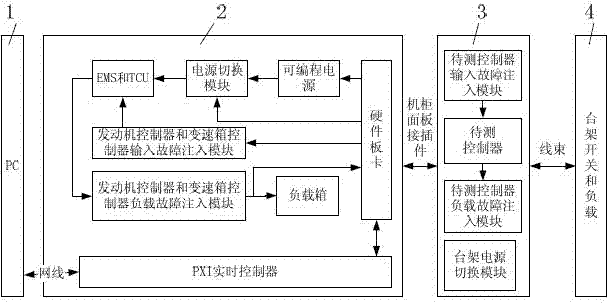

[0031] see figure 2 , a hardware-in-the-loop (HIL)-based vehicle body electronic control system test platform, including a host computer (PC) 1, a test cabinet 2, a movable terminal block 3 and a laboratory car bench 4.

[0032] The test cabinet 2 is composed of multiple modules, including cabinet power input module, programmable power supply, power switching module, engine controller (EMS) and transmission controller (TCU), load box, PXI real-time controller (lower computer ), engine controller and gearbox controller fault injection module, and hardware boards, among which hardware boards include engine analog signal generation module, analog signal generation module, analog signal measurement module, digital signal generation module, digital signal Measurement module, PWM signal generation module, PWM signal measurement module, resistance a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com