Alignment film and preparation method thereof, display panel and display device

A technology for display panels and alignment films, applied in chemical instruments and methods, instruments, liquid crystal materials, etc., can solve problems such as inability to eliminate afterimages, and achieve the effects of eliminating afterimages, reducing accumulation, and solving afterimage problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

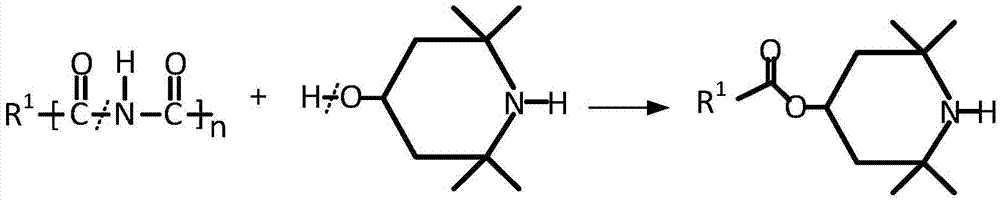

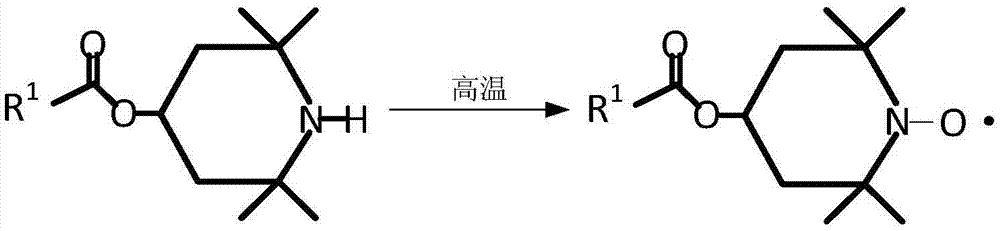

[0026] Please refer to figure 1 and figure 2 , This embodiment provides an alignment film, including a functional material produced by alcoholysis of polyimide and a trapping monomer, and the functional material is used to generate functional free radicals capable of trapping ionic impurities.

[0027] Wherein, the structural formula of the capture monomer is:

[0028] Among them, the structural formula of the functional material is in, is a group derived from polyimide.

[0029] Such as figure 1 The shown polyimide and capture monomer undergo alcoholysis reaction to generate functional groups. When polyimide and capture monomer react, the amide bond in polyimide The C-N bond of the figure 1 The chemical bond broken by the dashed line in the polyimide structure in the middle); capture monomer There are alcoholic hydroxyl groups in the structure, and when reacting with polyimide, the O-H bond in the alcoholic hydroxyl groups is broken (ie figure 1 The chemical bo...

Embodiment 2

[0039] Please refer to image 3 , this embodiment provides a method for preparing an alignment film, the alignment film is the alignment film described in Example 1, and the preparation method includes:

[0040] Step 101, alcoholysis reaction of polyimide and capture monomer to generate functional material.

[0041] Specifically, such as figure 1 The shown polyimide and capture monomer undergo alcoholysis reaction to generate functional groups. When polyimide and capture monomer react, the amide bond in polyimide The C-N bond of the figure 1 The chemical bond broken by the dashed line in the polyimide structure in the middle); capture monomer There are alcoholic hydroxyl groups in the structure, and when reacting with polyimide, the O-H bond in the alcoholic hydroxyl groups is broken (ie figure 1 The chemical bond broken by the dotted line in the capture monomer structure), that is to say, when the polyimide and the capture monomer undergo alcoholysis reaction, the polyi...

Embodiment 3

[0045] This embodiment provides a display panel, including the alignment film described in Embodiment 1, the alignment film is used to capture ion impurities when the display panel is displaying, and when the display panel finishes displaying The ionic impurities are separated.

[0046] Among them, ionic impurities include impurities introduced by alignment film materials, liquid crystal materials and color filters that affect display effects.

[0047] Specifically, the ionic impurities themselves refer to the impurities that have an impact on afterimages brought by the image film materials, liquid crystal materials, and resins used in color filters, such as -C produced by the decomposition of liquid crystal itself. 3 h 7 base, -CH 2 base, -F base, etc., as well as the protective layer in the color film, the black matrix, and the Na + , Cl - Plasma.

[0048] Please refer to Figure 4 , where, with R 2 Indicates ionic impurities. When the functional free radicals in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com