Centering device for tyre static balance detection

A technology of centering device and detection device, applied in measurement device, static/dynamic balance test, machine/structural component test, etc., can solve problems such as low detection efficiency, laborious, time-consuming and frequent, and reduce physical labor intensity. , Improve detection efficiency, reduce the effect of wasted time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

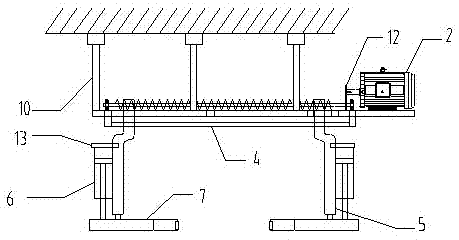

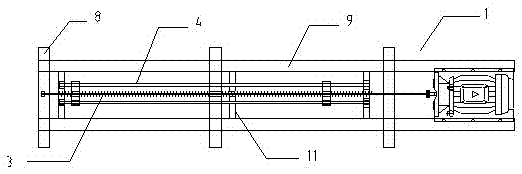

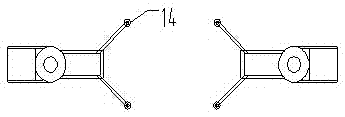

[0017] Such as Figure 1 to Figure 3 A centering device for tire static balance detection is shown, a detection platform is installed below the tire static balance detection device, and a beam is placed above the tire static balance detection device, and it is characterized in that it includes a fixing device 1, a transmission device and a pushing device .

[0018] The fixing device includes an upper beam 8, a bottom beam 9 and a suspender 10; the upper beam 8 is fixed on the beam by bolts, and the upper end of the suspender 10 is welded on both sides of the upper beam 8 along the vertical direction, and the bottom beam 9 has two groups, Several groups of suspenders 10 are welded on the bottom beam 9, and the two groups of bottom beams 9 are respectively welded to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com