Sealing ring for composite steel pipe connection

A technology of composite steel pipe and sealing ring, which is applied in the direction of engine sealing, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc. Achieve the effect of ensuring hygienic indicators, prolonging service life, and ensuring safe transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical features, technical content and technical effects of the present invention, the accompanying drawings of the present invention will now be described in more detail in conjunction with the embodiments.

[0021] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

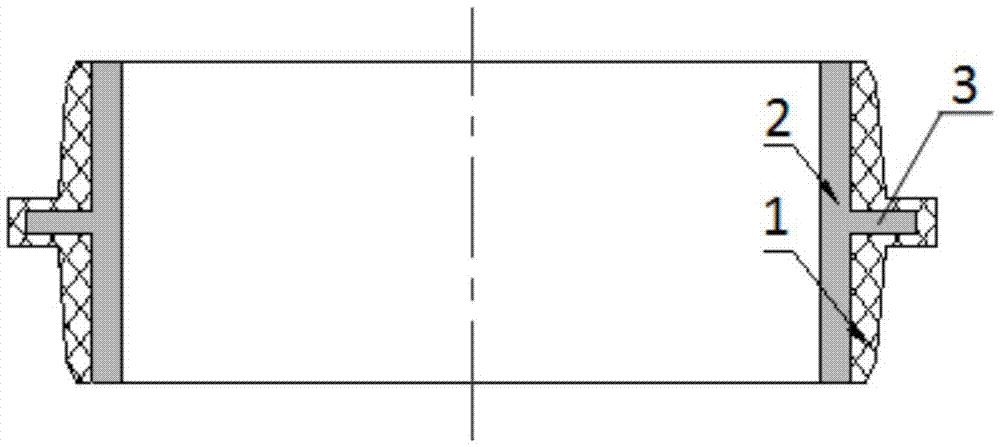

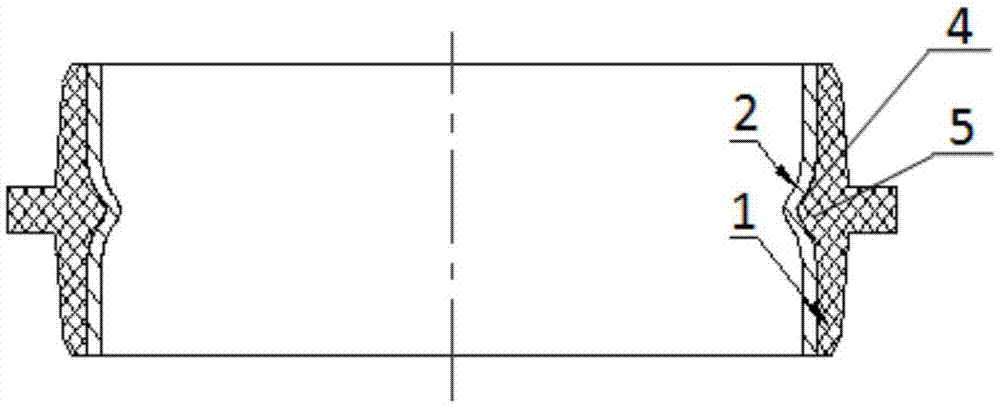

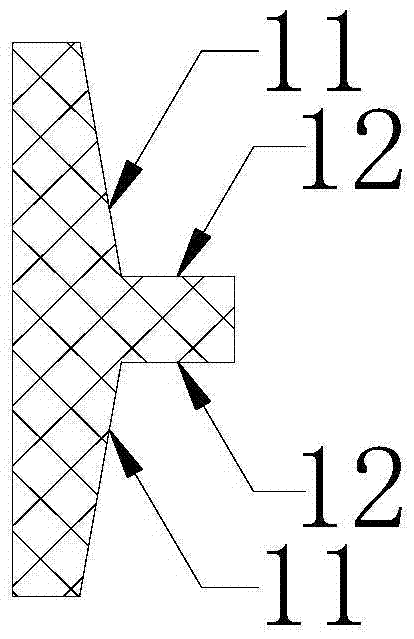

[0022] The invention provides a sealing ring for composite steel pipe connection, which includes a supporting frame 2 and a sealing body 1. When in use, the supporting frame 2 is fixedly connected with the inner wall of the sealing body 1, and the sealing body 1 includes a The inner sealing surface 11 in the mouth and the end sealing surface 12 integrally formed with the inner sealing surface 11, the inner sealing surface 11 is two, symmetrically arranged on both sides of the end sealing surface 12. The sealing body 1 is made of food-grade rubber.

[0023] The included angle between the inner sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com