Valve rocker assembly of motorcycle engine

A valve rocker arm and engine technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as inaccuracy, affecting engine elimination effect, abnormal noise elimination effect, etc., to improve noise reduction effect, low implementation cost, Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

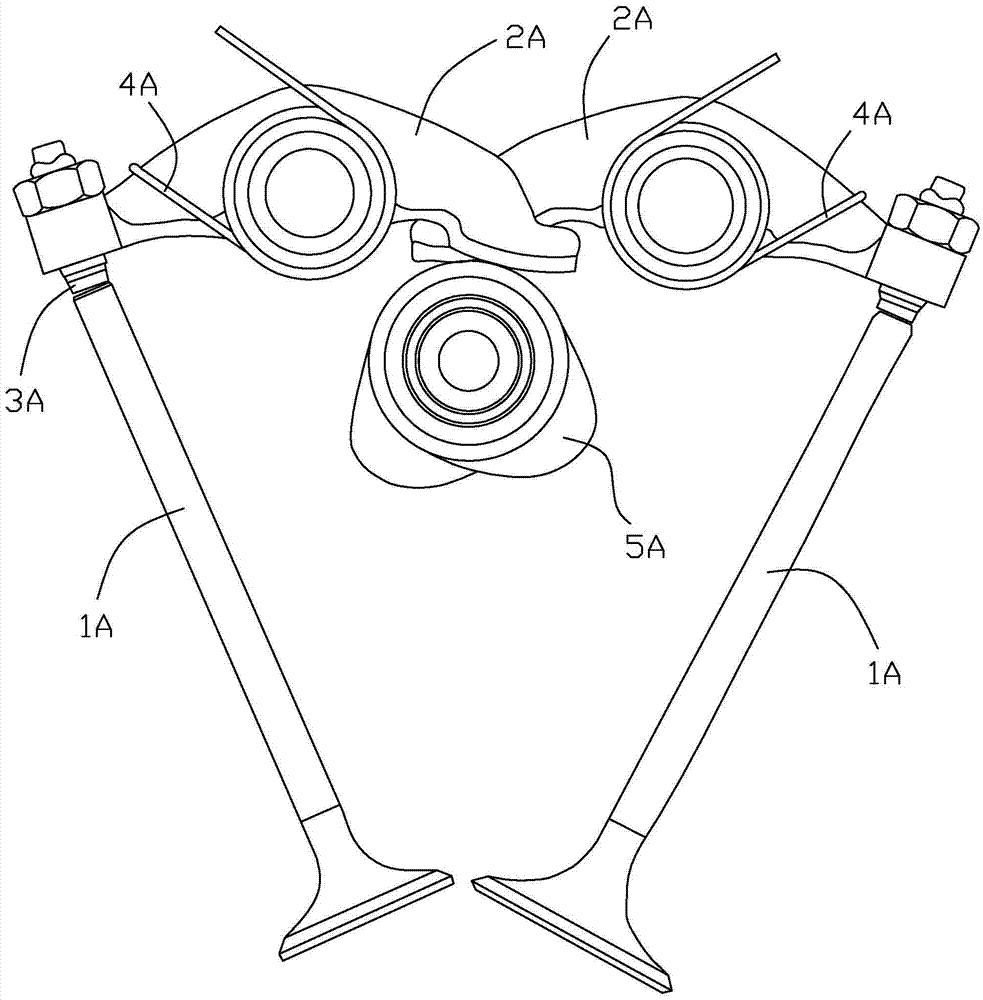

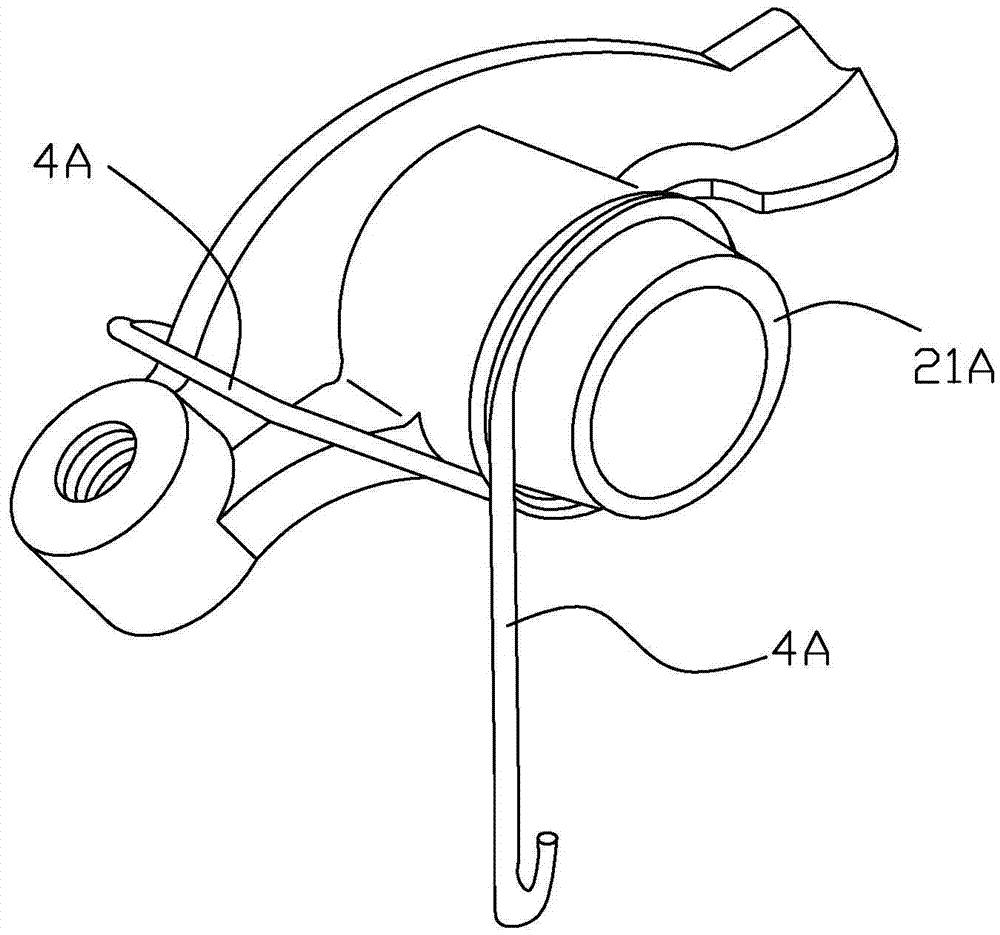

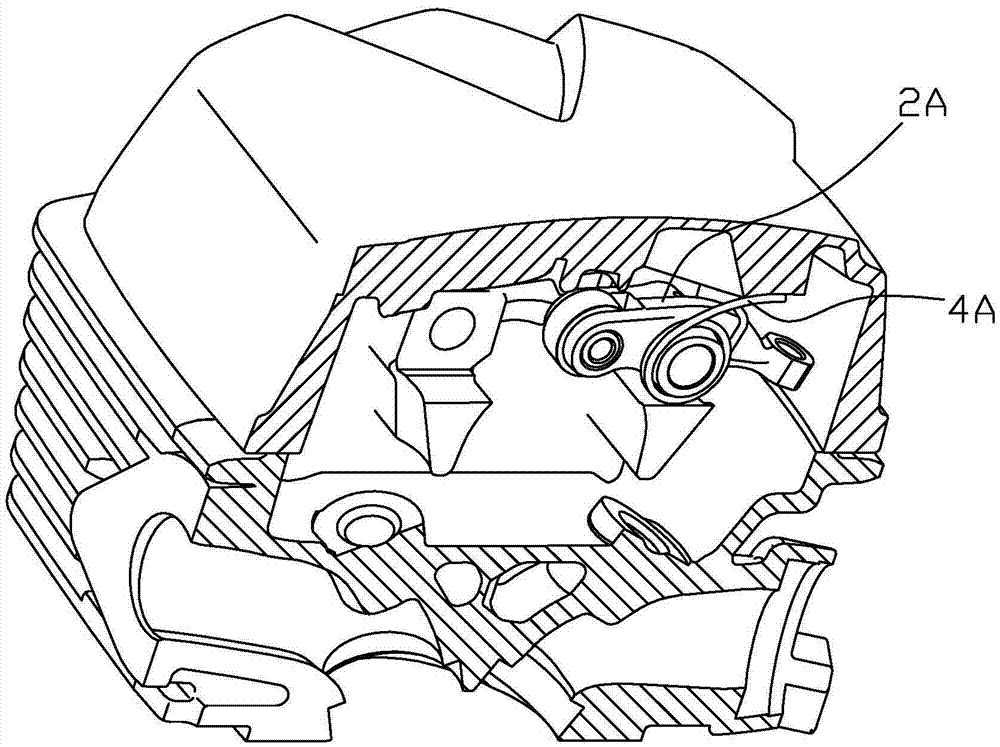

[0029] refer to Figure 5~Figure 12 , a valve rocker arm assembly of a motorcycle engine of the present invention, including a rocker arm 1 assembled on a cylinder head rocker shaft (not shown) and a torsion spring 2 for applying a preload to the rocker arm 1, the rocker The arm 1 has a cam end 11 and a valve end 12 respectively located on the left and right sides of the rocker shaft of the cylinder head. In the prior art, the valve end 12 is equipped with an adjusting nut 3A (see figure 1 ), the adjusting nut 3A is used to adjust the gap between the rocker arm 1 and the tappet, so as to ensure that the rocker arm can accurately transmit the change of the head of the cam profile, so as to correctly control the flow of oil and gas into the cylinder combustion chamber, and to promote the engine to run and then discharge the exhaust gas Timing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com