Sprayer device for jetting concrete

A technology of sprayed concrete and concrete, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of insufficient mixing of water and dry mixture, endangering the health of workers, reducing the strength of the sprayed surface, etc., and achieves the reduction of rebound rate , the effect of area increase and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

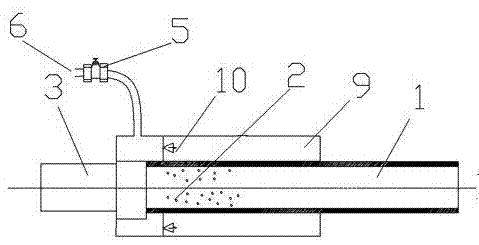

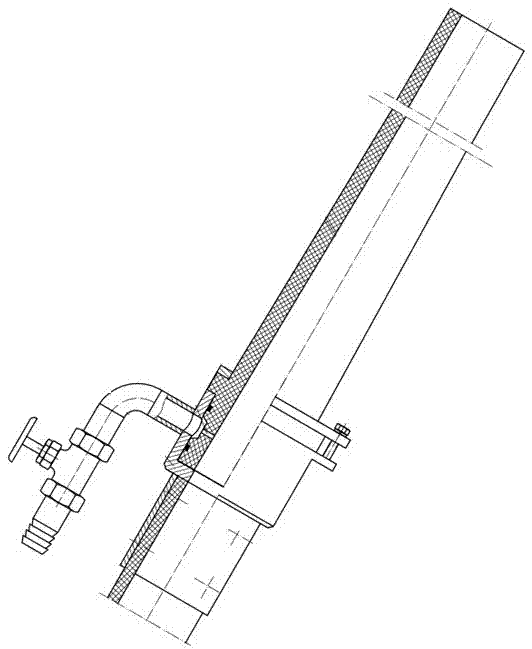

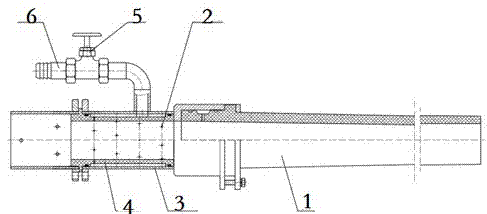

[0030] Embodiment one of the nozzle device for shotcrete of the present invention, as Figure 1~7 As shown, it includes the water inlet 6, the valve 5, the nozzle seat 3 and the nozzle 1. The nozzle seat 3 is provided with a channel for concrete spraying. The nozzle 1 communicates with the nozzle seat 3. There is a columnar water ring chamber connected to the water inlet 6, and a valve 5 for controlling the opening and closing of the water pipe is installed between the water inlet 6 and the water ring sleeve 4, and the water ring sleeve 4 is between the channel and the water ring chamber. 4 to 8 end faces of the water ring sleeve 4 with a certain distance in the axial direction are provided with 4 to 8 water filling holes connecting the water ring cavity and the channel, such as Figure 4~7 As shown, the water ring sleeve in this embodiment is provided with four end faces for opening water filling holes 2, and the water filling holes on each end face are all staggered by a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com