Movable automatic feeding and concrete spraying device

A shotcrete and automatic feeding technology, applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of high labor intensity, high labor intensity, poor quality of shotcrete, etc. Convenient and fast, easy to install and connect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in combination with specific embodiments.

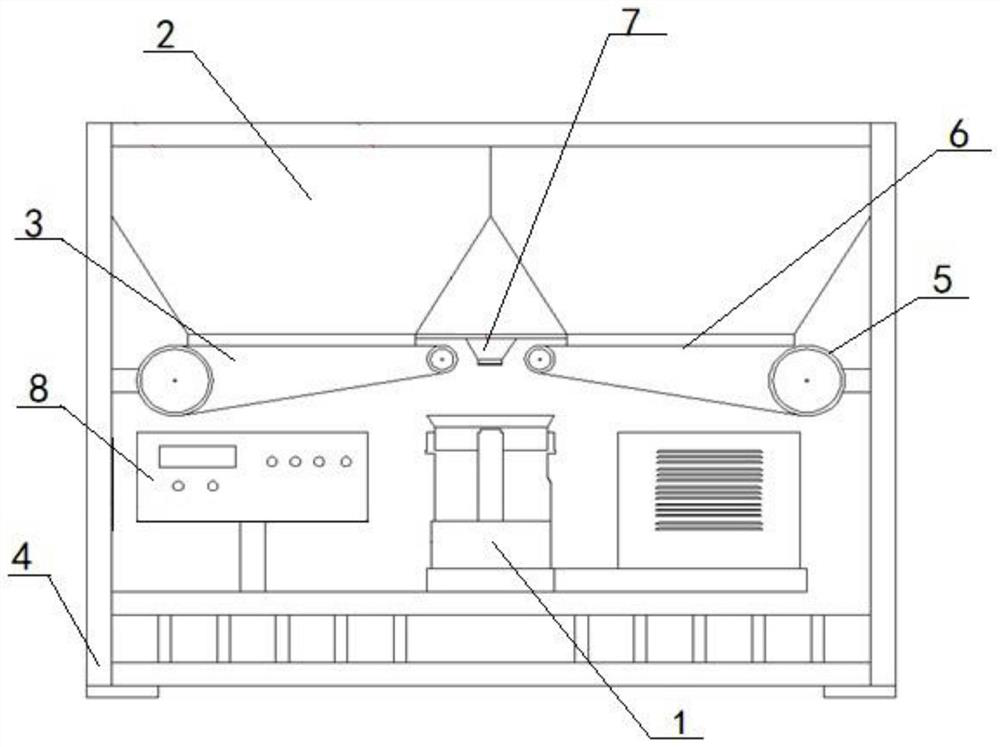

[0014] Such as figure 1 As shown, a mobile automatic feeding shotcrete device includes a dry shotcrete machine 1, a conical silo 2, a feeding system 3 and a unit frame 4. The feeding system 3 includes two sets of symmetrically arranged belt conveying mechanisms, and the belt The conveying mechanism includes an electric drum 5 and a conveying belt 6. Two conical silos 2 are respectively arranged above the conveying belt, and are opened at the bottom in cooperation with the conveying belt. An elastic silo 7 is set in the middle of the two conical silos for the quick-setting agent. and other additives are transported together, and a vibration motor is installed in the elastic silo, and a dry shotcrete machine 1 is installed at the lower part of the opposite discharge port of two sets of belt conveying mechanisms, and the dry shotcrete machine 1 is fixed on the unit frame 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com