Double spray gun structure RH fining furnace soaking tube spraying machine

The technology of refining furnace and double spray gun is applied in the field of dipping pipe gunning machine of RH refining furnace, which can solve the problems of scrapping the dipping pipe, increase the cost of steelmaking, and difficult to operate, and achieve flexible and free gunning action, improve operation efficiency, and ensure that it is in place. Action-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

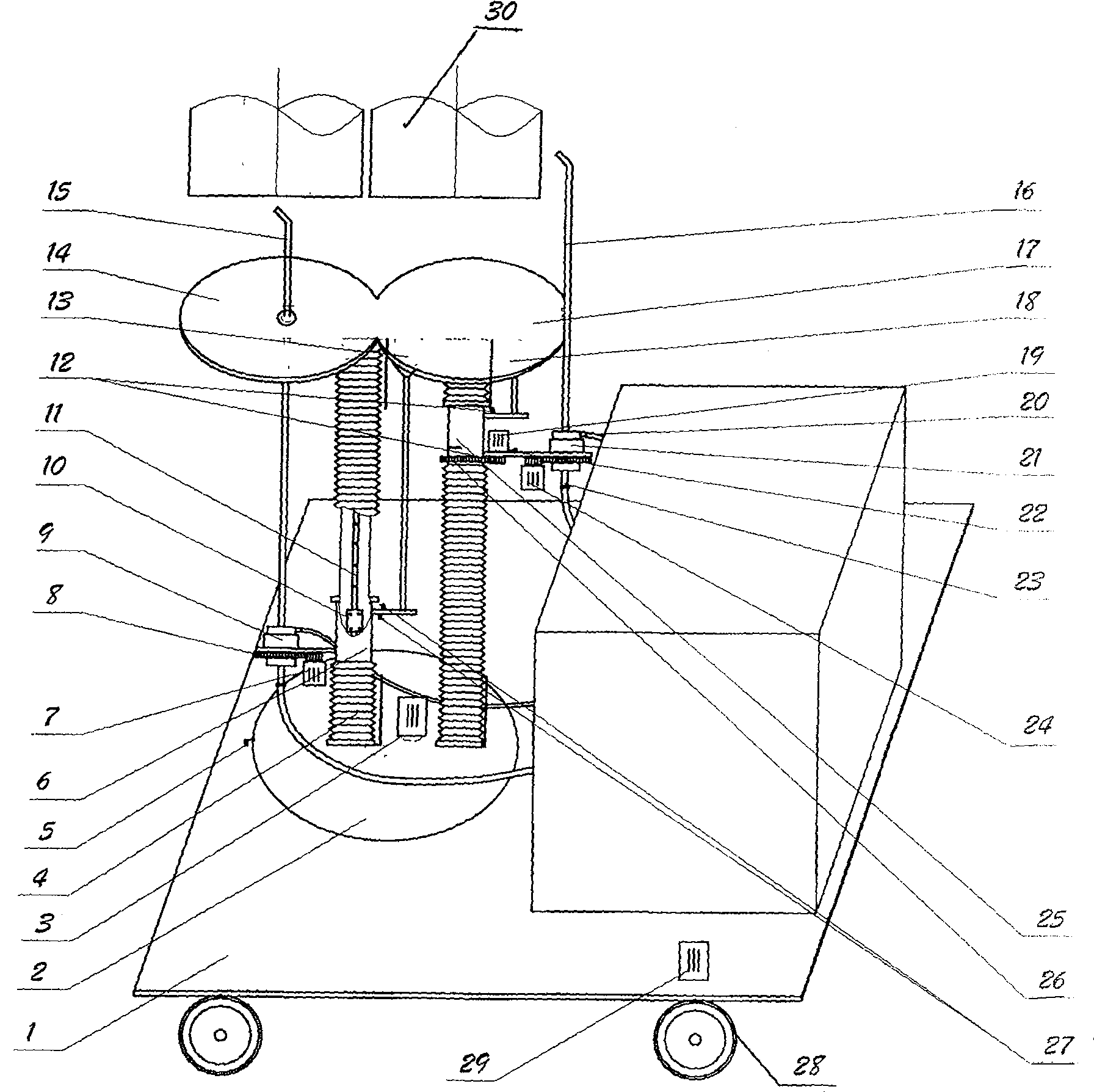

[0030] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as figure 1 As shown, the RH refining furnace immersion tube gunning machine with double spray gun structure of the present invention is characterized in that it consists of a traveling trolley, and the spray gun transposition rotary device arranged on the trolley is arranged on the spray gun transposition rotary device The outer spray gun and the outer spray gun rotary device, the outer spray gun self-running device, the inner spray gun and the inner spray gun self-running device arranged on the spray gun transposition rotary device, and the devices connected to the above-mentioned devices on the walking trolley made up of subsidiary systems,

[0032] 1) The spray gun transposition and turning device is arranged on the walking trolley 1, the bottom circular turntable 2, the gear rotation drive device 3 arranged on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com