A hoop type non-slip universal wall connecting piece with anti-slip block

A technology of connecting wall parts and anti-slip blocks, which is applied to the accessories of scaffolding, building structure support, building structure support, etc., can solve the problems of cumbersome construction operation procedures, insufficient anti-sliding force and strength, and reduce wall strength, etc., to achieve good results. Promote the application value, save labor and materials in production, and have obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

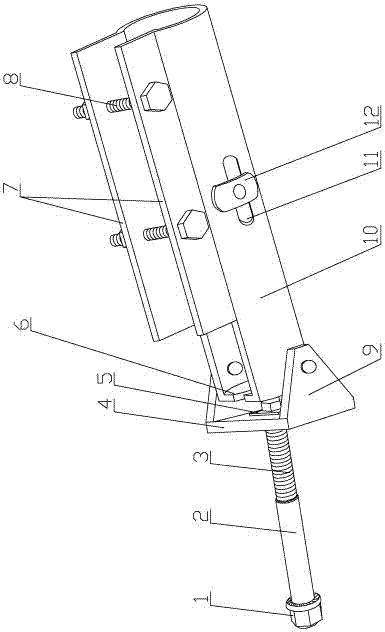

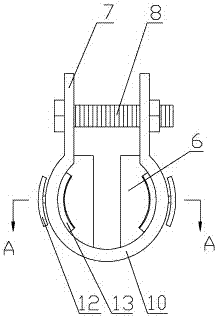

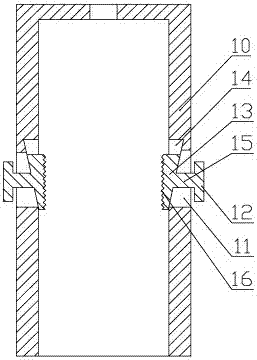

[0020] see Figure 1-Figure 4 , the present invention is a hoop type non-slip universal wall connecting piece with anti-slip block, which has a wall connecting piece body, the wall connecting piece body includes a connecting wall base 4, and a tension bolt 3 is pierced in the middle of the connecting wall base, so The rod of the tension bolt is provided with a thread, and the cap nut 1 with a PVC sleeve 2 is set on the thread; the other side of the wall base opposite to the tension bolt is hinged with a set of anti-skid block type anti-skid assembly, and the anti-skid The block type anti-slip assembly includes an anti-slip hoop 10, one end of which is hinged to the base of the wall, and the upper part of the anti-slip hoop is provided with an opening structure, and two connecting plates 7 are arranged on the opening structure. The bolt 8 is connected with the nut, and by adjusting the tightness of the nut, the two connecting plates can be clamped or loosened to realize the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com