Swivel system and construction method for swivel construction of large-span continuous beam span existing station

An existing station, large-span technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult construction, large turning span, heavy beam weight, etc. The effect of physical process safety and construction process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

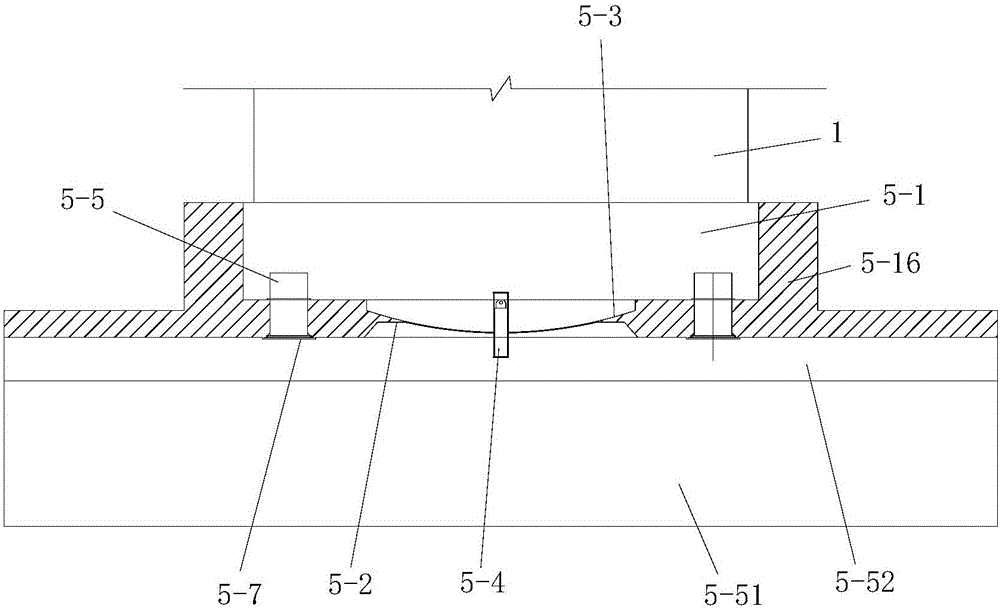

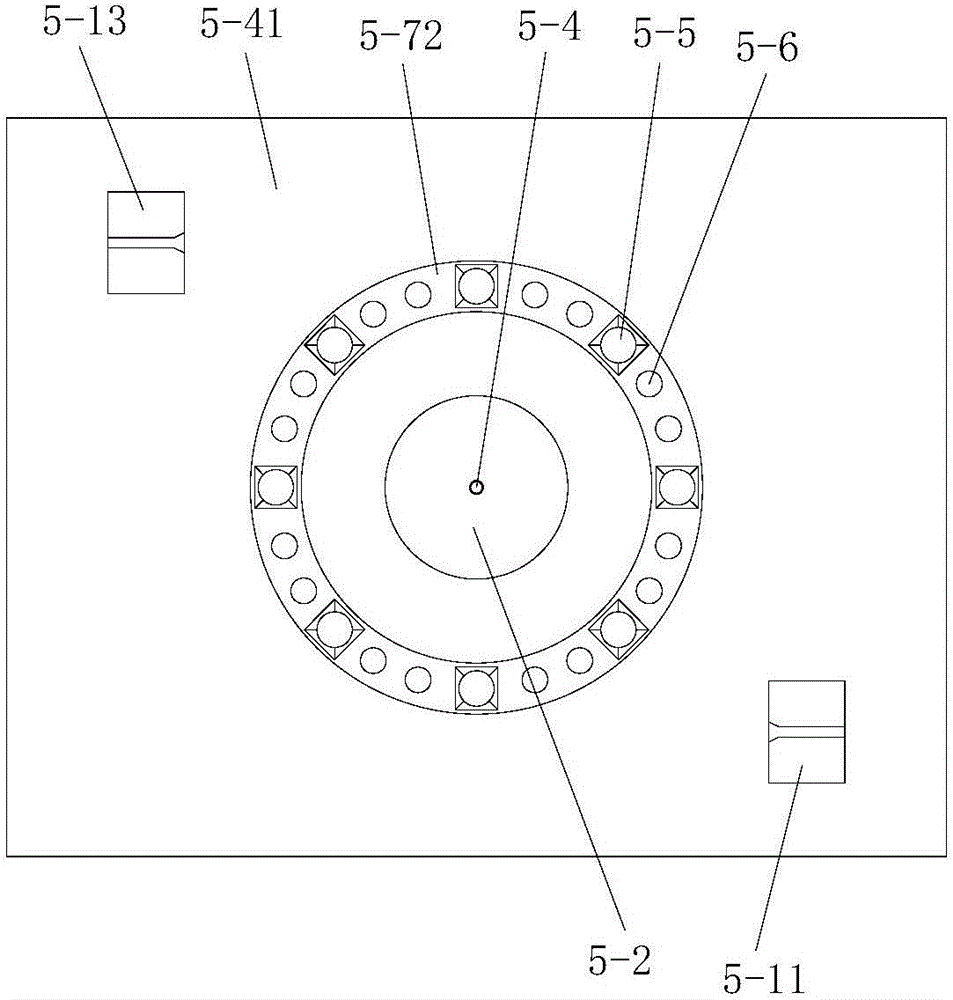

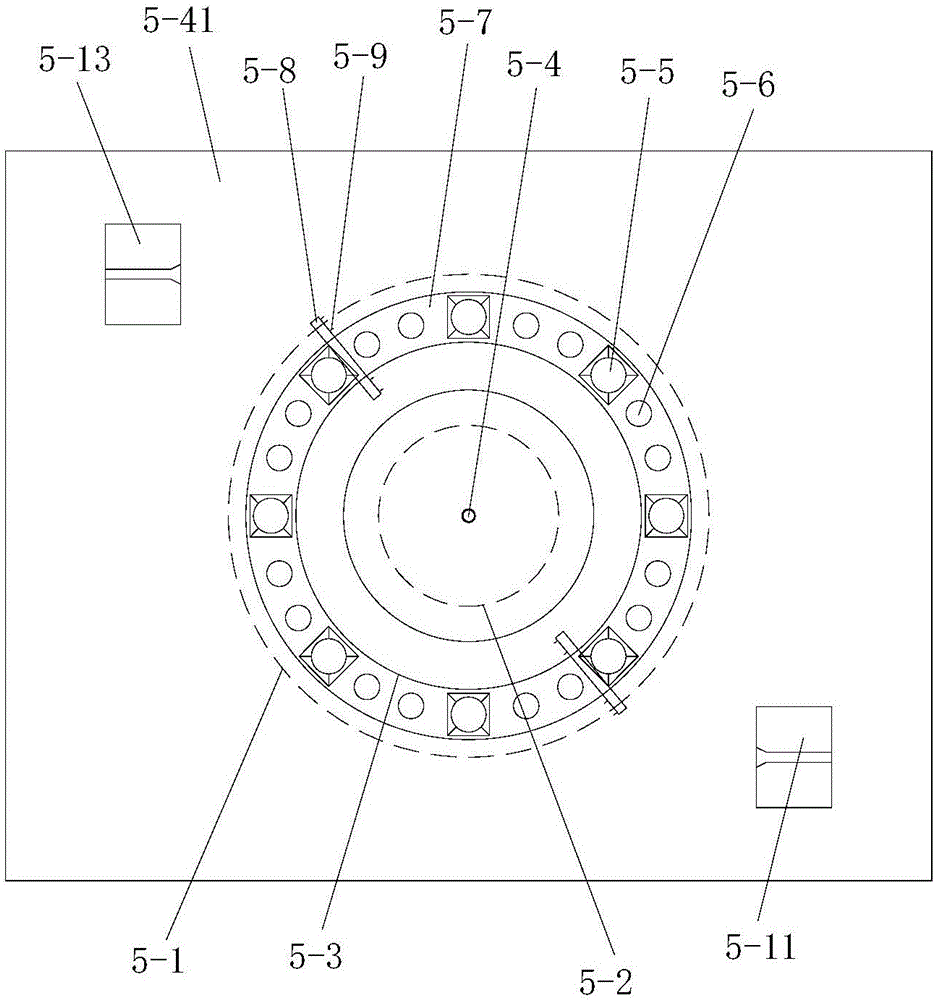

[0056] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown is a large-span continuous beam-span existing station swivel construction swivel system, including a lower support plate, which is located directly above the lower support plate and drives the mid-span pier of the constructed long-span continuous beam to rotate synchronously The upper turntable 5-1, the bridge swivel ball joint installed between the lower support plate and the upper turntable 5-1, and the swivel traction system that drives the upper turntable 5-1 to rotate on the horizontal plane, the lower support Both the disc and the upper turntable 5-1 are reinforced concrete structures and both are arranged horizontally, and the swivel traction system is connected with the upper turntable 5-1; the bridge swivel spherical hinge includes a lower spherical hinge 5-2, The upper spherical hinge 5-3 installed directly above the lower spherical hinge 5-2, the pivot pin 5-4 connected between the lower spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com