Antibacterial mite-proofing finishing agent and preparation method thereof

A finishing agent and anti-mite technology, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc. It can solve the problems that the safety performance cannot be guaranteed, contact with human skin, and it is not suitable for long-term use, so as to avoid direct contact with human skin , Inhibit mites, improve the effect of safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

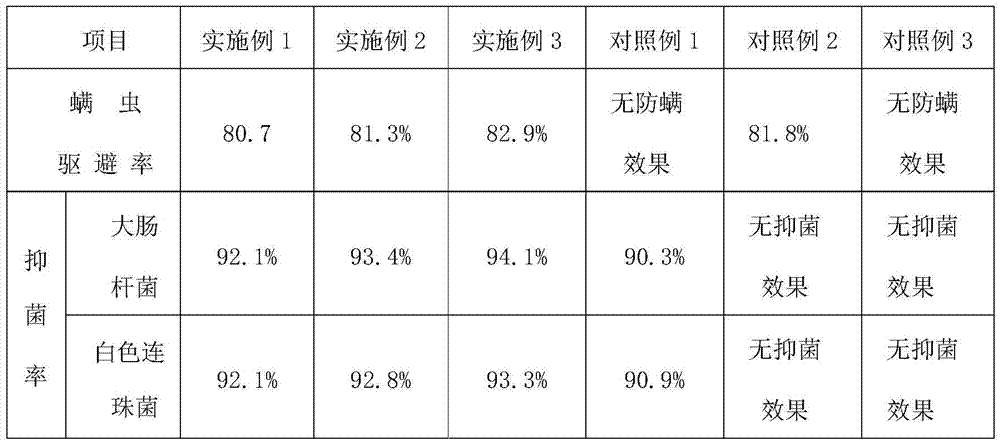

Examples

Embodiment 1

[0024] An antibacterial and anti-mite finishing agent, comprising in parts by weight:

[0025] Antibacterial and anti-mite microcapsules: 3 parts;

[0026] Sodium hexametaphosphate: 3 parts;

[0027] Span-60: 4 servings;

[0028] Water-based polyurethane: 6 parts;

[0029] Glutaraldehyde: 2 parts;

[0030] Water: 85 parts.

[0031] Antibacterial and anti-mite microcapsule formula:

[0032] Capsule core: neem oil: 10%, glyceryl undecylenate: 3%, olive oil: 87%;

[0033] Wall material: gelatin.

[0034] Add the emulsifier Span-60 into the water, mix well, add antibacterial and anti-mite microcapsules and stir well, then add the dispersant sodium hexametaphosphate, binder water-based polyurethane, crosslinking agent glutaraldehyde, mix and add Stir evenly in a mixer with a rotating speed of 1000rpm to obtain the antibacterial and anti-mite auxiliary agent.

Embodiment 2

[0036] An antibacterial and anti-mite finishing agent, comprising in parts by weight:

[0037] Antibacterial and anti-mite microcapsules: 5 parts;

[0038] Sodium tripolyphosphate: 4 parts;

[0039] Span-80: 7 servings;

[0040] Polyacrylate: 10 parts;

[0041] 1,3-dichloro-2-propanol: 4 parts;

[0042] Water: 85 parts.

[0043] Antibacterial and anti-mite microcapsule formula:

[0044] Capsule core: Neem oil: 12%, Glyceryl undecylenate: 4%, Olive oil: 84%;

[0045] Wall material: gelatin.

[0046] Add emulsifier Span-60 into water, mix well, add antibacterial and anti-mite microcapsules and stir well, then add dispersant sodium tripolyphosphate, binder polyacrylate, crosslinking agent 1,3-dichloro - 2-propanol, after mixing, add it into a mixer with a rotating speed of 1300rpm and stir evenly to obtain the antibacterial and anti-mite auxiliary agent.

Embodiment 3

[0048] An antibacterial and anti-mite finishing agent, comprising in parts by weight:

[0049] Antibacterial and anti-mite microcapsules: 8 parts;

[0050] Sodium pyrophosphate: 5 parts;

[0051] Glyceryl monostearate: 10 parts;

[0052] Fatty acid binder: 15 parts;

[0053] Polyethylene glycol diglycidyl ether: 6 parts;

[0054] Water: 56 parts.

[0055] Antibacterial and anti-mite microcapsule formula:

[0056] Capsule core: neem oil: 15%, glyceryl undecylenate: 5%, olive oil: 80%;

[0057] Wall material: Chitosan.

[0058] Add the emulsifier glyceryl monostearate into the water, mix well, add antibacterial and anti-mite microcapsules and stir well, then add the dispersant sodium pyrophosphate, binder fatty acid binder, crosslinking agent polyethylene glycol Alcohol diglycidyl ether, after mixing, add it to a mixer with a rotation speed of 1500 rpm and stir evenly to obtain the antibacterial and anti-mite auxiliary agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com