Separated cavity type hydrogen and oxygen separating electrolyser and method thereof

An electrolysis device, hydrogen-oxygen technology, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of inability to realize pure hydrogen production, inability to separate hydrogen and oxygen, and online gas separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

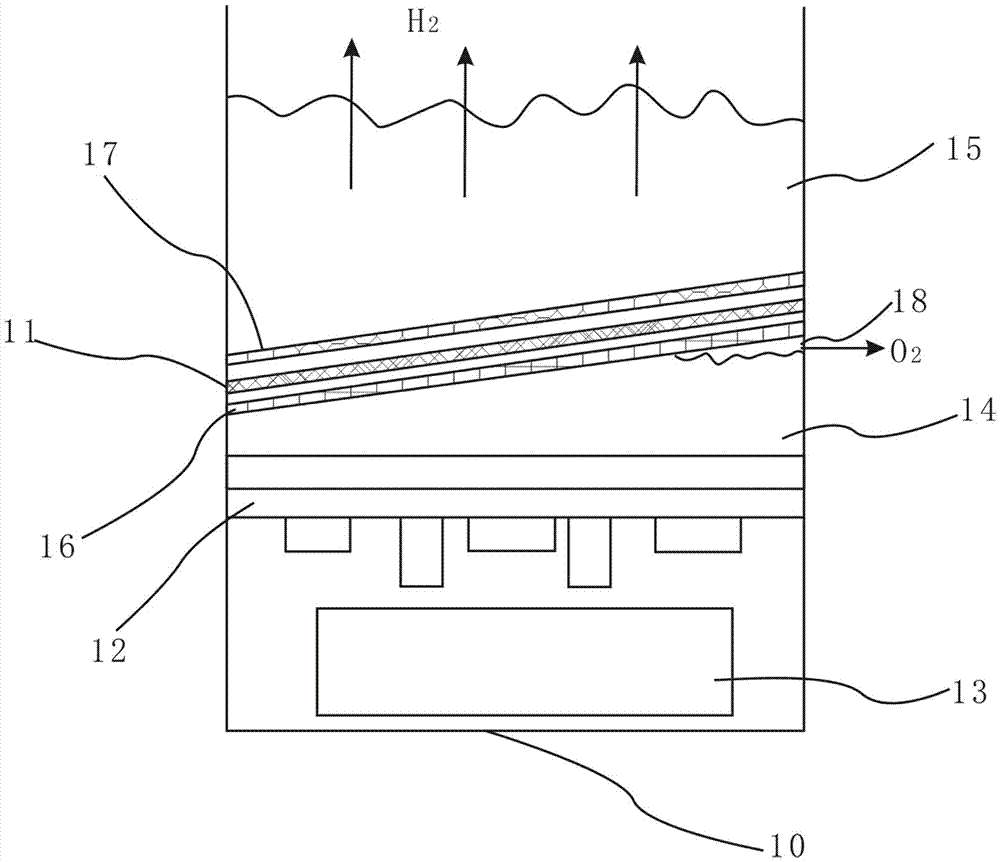

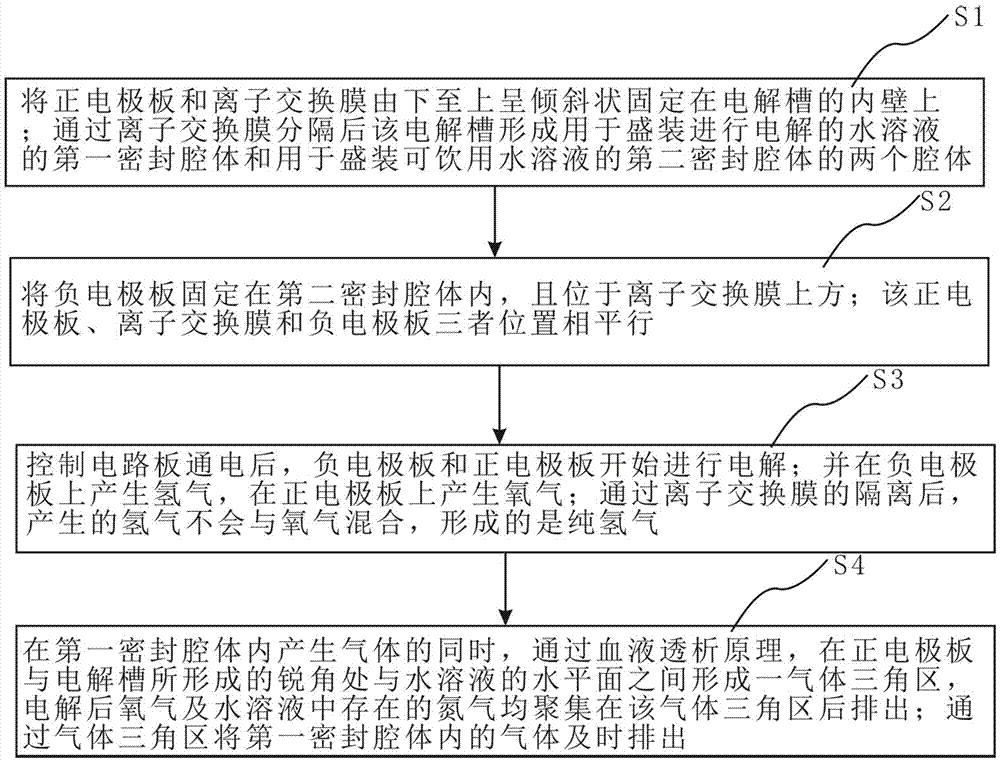

[0032] see figure 1 , the sub-chamber hydrogen-oxygen separation electrolysis device of the present invention comprises an electrolytic cell 10, an ion exchange membrane 11, a control circuit board 12 and a lithium battery 13; the edge of the ion exchange membrane 11 is sealed and fixed on the inner wall of the electrolytic cell 10, and the electrolytic cell 10 is separated by an ion exchange membrane 11 to form a first sealed cavity 14 for containing electrolyzed water and a second sealed cavity 15 for containing drinking water. The first sealed cavity 14 is located below the ion exchange membrane 11 , the second sealed cavity 15 is located above the ion exchange membrane 11; the control circuit board 12 and the lithium battery 13 are fixed in the bottom of the electrolytic cell 10, and the lithium battery 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com