Intelligent refreshing barrel

A wine barrel, intelligent technology, applied in liquid distribution, household components, applications, etc., can solve problems such as damage, the appearance of the outer layer cannot be guaranteed, and the storage aging of the liquid in the barrel cannot be effectively counted. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

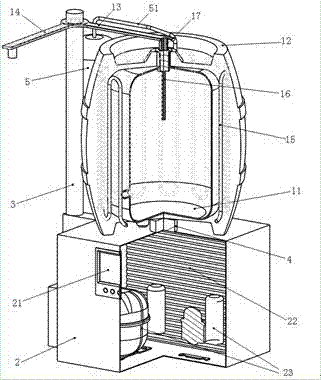

[0033] Example 1 Intelligent fresh-keeping wine barrel

[0034] An intelligent fresh-keeping wine barrel, comprising a barrel body 1, a low-temperature cooling control box 2 and a column 3, wherein the barrel body 1 includes a barrel inner body 11 and an outer insulation layer 12 of the barrel, and the barrel inner body The top is fixed on the top of the barrel body 11 through the swing arm, a motor is arranged in the hollow shaft of the swing arm, and a wine spear 16 is installed under the motor, and the wine spear 16 is threadedly connected with the inner barrel body 11 barrel neck and extends into In the inner tank, one end of the swing arm 13 is rotatably connected to the column 3, and the other end is connected to the boss on the top of the barrel inner tank through the hollow shaft of the swing arm. Cooling water pipes 15 are arranged along the circumference, and the outer thermal insulation layer of the wine barrel is a low thermal conductivity hard foam layer formed by...

Embodiment 2

[0035] Example 2 Foam injection molding of low thermal conductivity hard foam layer

[0036] (8.1) 100 parts by weight of polyether, 1.5 parts by weight of silicone oil, 0.1 parts by weight of water, 1.2 parts by weight of cyclohexylamine, 27 parts by weight of cyclopentane, 3-5 parts by weight of color paste, 1.325 parts by weight The UV absorber of part, the foam stabilizer of 1.5 parts by weight, the dimethylcyclohexylamine of 2 parts by weight and the polyurethane white material of the HFC-245fa of 30 parts by weight-import in the white material barrel of high-pressure or low-pressure foaming machine, Lead polyurethane black material polymethylene polyphenyl polyisocyanate into high-pressure or low-pressure foaming machine black material barrel, and heat or dissipate heat to material temperature 22°C respectively, and barrel pressure is 0.2kg / cm 2 , wherein, the isocyanate index of polymethylene polyphenyl polyisocyanate is 1.0, the thermal conductivity is lower than 20mW / ...

Embodiment 3

[0040] Embodiment 3 The foaming injection molding of low thermal conductivity hard foam layer

[0041] (8.1) 100 parts by weight of polyether, 1.5 parts by weight of silicone oil, 0.1 parts by weight of water, 1.2 parts by weight of cyclohexylamine, 27 parts by weight of cyclopentane, 3-5 parts by weight of color paste, 1.325 parts by weight The polyurethane white material of the UV absorber of part, the foam stabilizer of 2.5 parts by weight, the dimethylcyclohexylamine of 4 parts by weight and the HFC-245fa of 40 parts by weight one imports in the white material barrel of high-pressure or low-pressure foaming machine, Introduce polyurethane black material polymethylene polyphenyl polyisocyanate into the black material barrel of high-pressure or low-pressure foaming machine, and heat or dissipate heat to the material temperature of 35°C respectively, and the barrel pressure is 0.5kg / cm 2 , wherein, the isocyanate index of polymethylene polyphenyl polyisocyanate is 1.0, the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com