Bamboo fibrillating-rolling device

A broomification and equipment technology, which is applied in the field of bamboo broomification and rolling equipment, can solve the problems of increased product cost, soaring price, and high density of recombined bamboo, so as to improve the mechanical strength and bonding strength, solve the problem of difficult bonding, and reduce the transverse strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

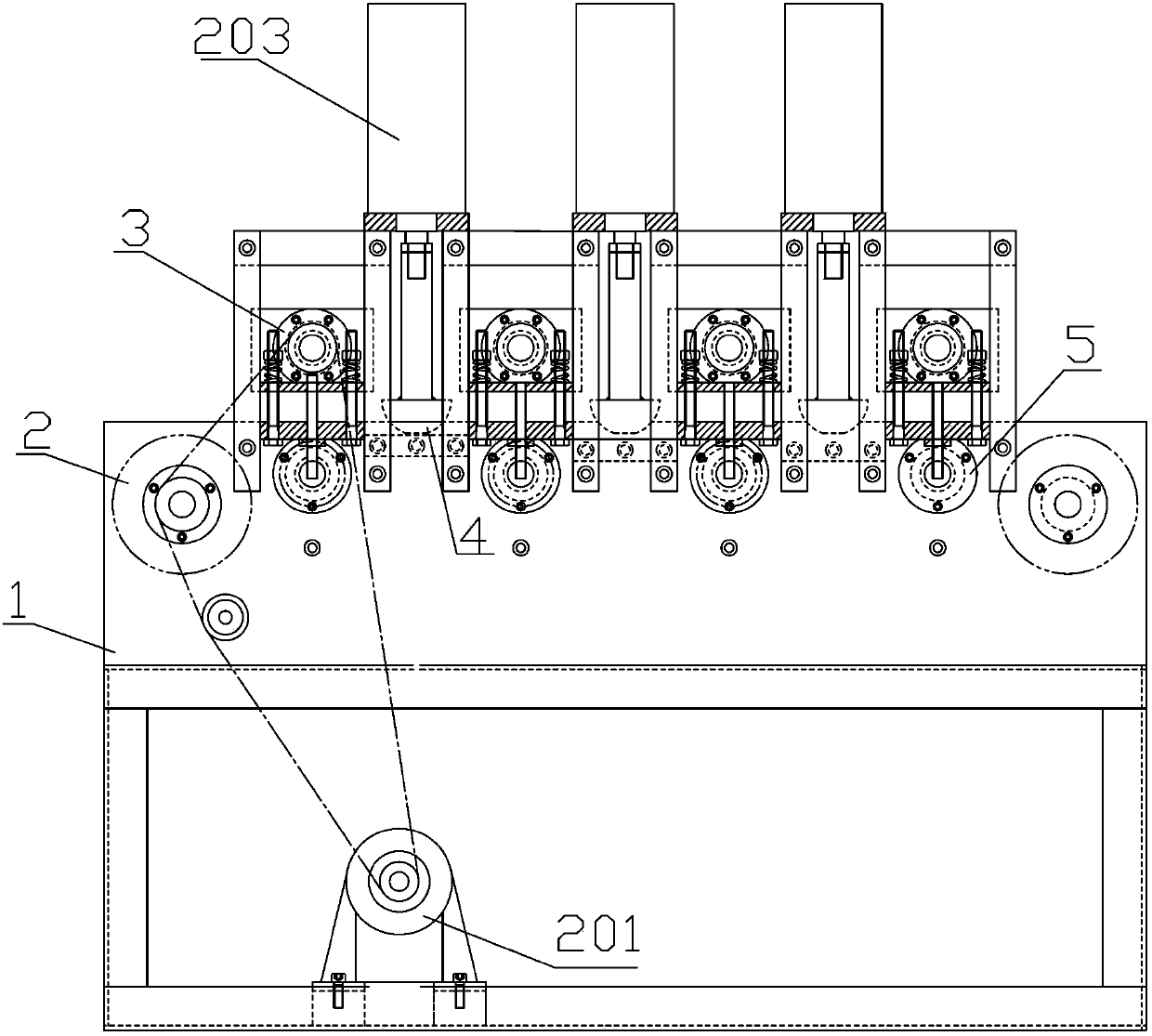

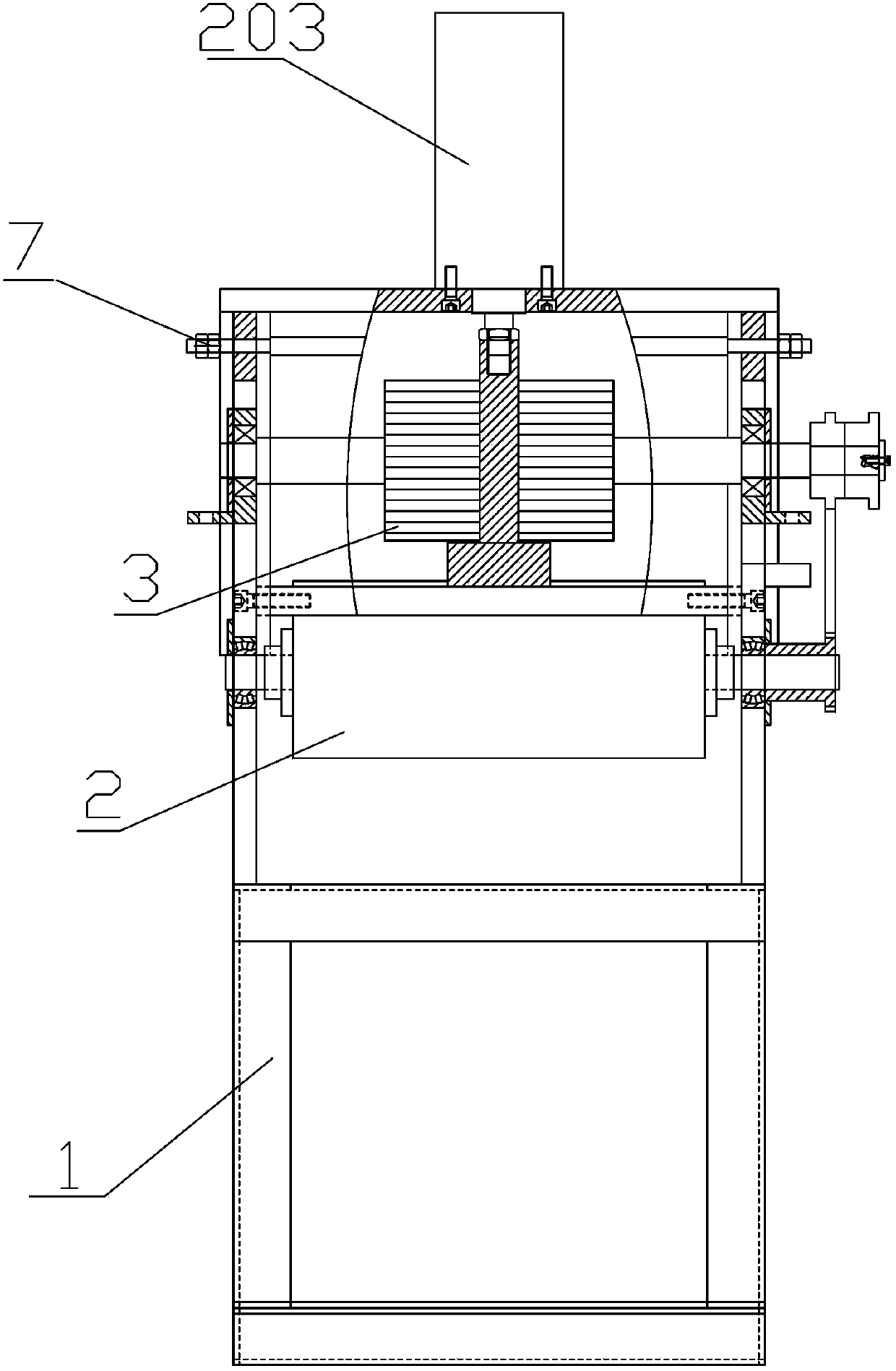

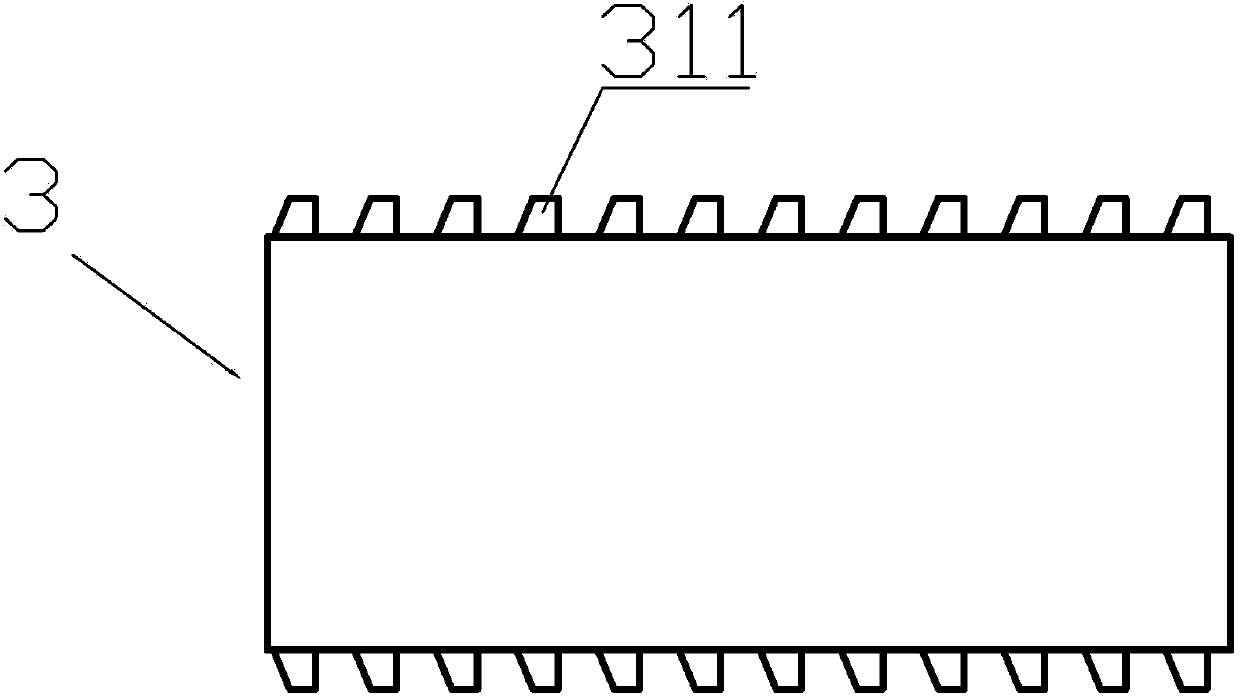

[0028] refer to figure 1 , figure 2 Shown is a basic embodiment of the bamboo brooming and rolling equipment of the present invention, including a frame 1, a transmission mechanism 2, a brooming mechanism 3, a beating mechanism 4 and a rolling mechanism 5.

[0029] First of all, the main purpose of the bamboo broomification and rolling equipment of the present invention is for further deep processing of bamboo (broomification, beating and rolling). Before entering the equipment of the present invention, the bamboo to be processed should be pre-treated: remove bamboo If there are no knots, the "arrow shaft" can be used to remove the internal diaphragm of bamboo, and it is not necessary to remove bamboo knots for small-diameter bamboo stalks.

[0030] The frame 1 is the supporting frame of the whole equipment, on which the brooming, beating and rolling operation areas of the brooming mechanism 3, the beating mechanism 4 and the rolling mechanism 5 are designed, and these opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com