Process for producing reaction bonded silicon carbide member

A technology of sintered silicon carbide and manufacturing method, which is applied in the direction of processing and manufacturing, manufacturing tools, ceramic molding machines, etc., and can solve the problem that large and complex shapes cannot be obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

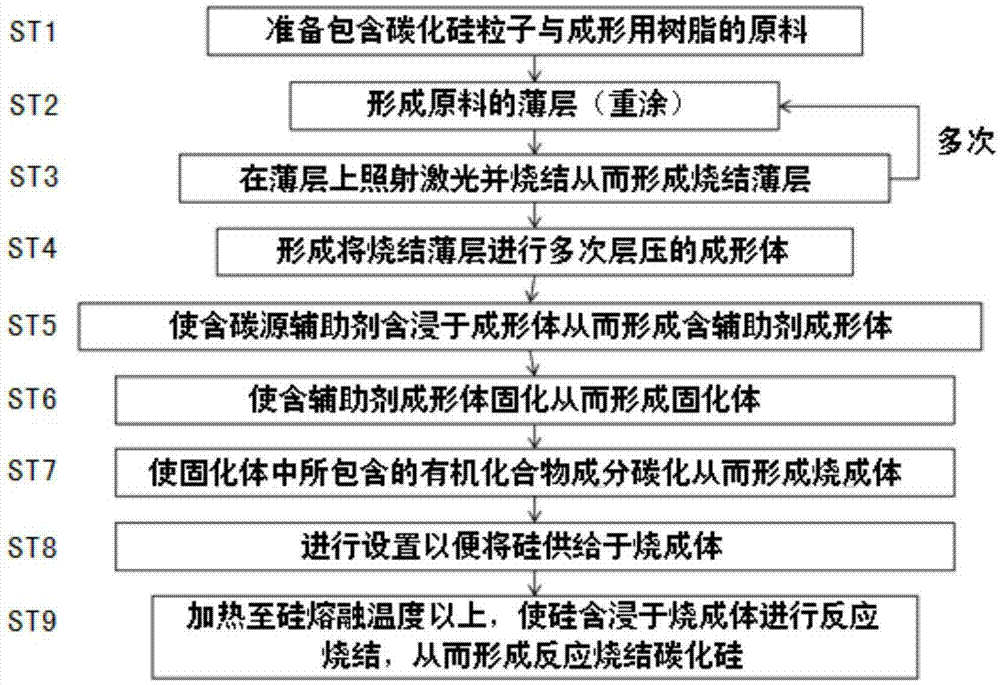

Method used

Image

Examples

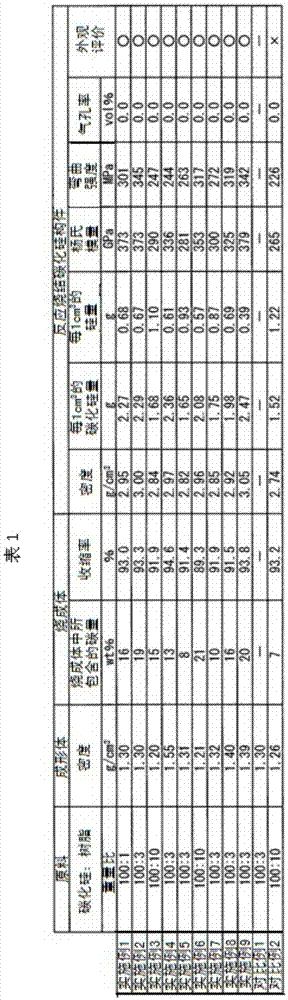

Embodiment 1

[0120] Raw material preparation

[0121] As raw materials, silicon carbide (SiC) with an average particle diameter of 30 μm and nylon 12 with an average particle diameter of 10 μm were used. Weighing was performed as follows so that the weight ratio (former:latter) of silicon carbide powder to nylon 12 became 100:1. 10 kg of the above-mentioned mixed powder was put into a plastic tank, and dry stirring and mixing were performed for more than 2 hours to obtain a raw material.

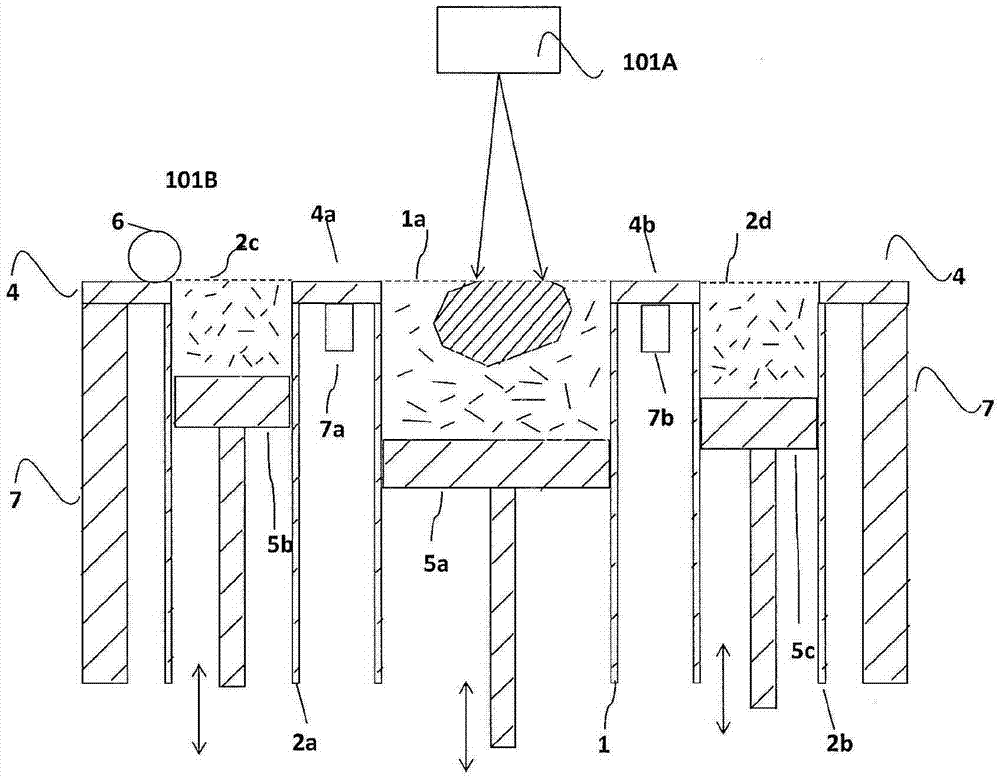

[0122] Forming

[0123] As the powder sintering lamination molding apparatus, a powder lamination type 3D molding apparatus (SEMplice300, manufactured by Aspect Corporation) was used. A predetermined amount of the obtained raw material was put into the raw material container so that it could be filled without unevenness. Next, the raw material container filled with the raw material is mounted on the main body of the apparatus, and then nitrogen is introduced into the molding chamber. Then, a thin lay...

Embodiment 2

[0138] A reaction-sintered silicon carbide member was produced in the same manner as in Example 1 except that the weight ratio of silicon carbide powder to nylon 12 was 100:3 to obtain the raw material. Then, in the same manner as in Example 1, silicon on the surface of the reaction-sintered silicon carbide member was removed, and various evaluations were performed after processing into a desired shape.

Embodiment 3

[0140] A reaction-sintered silicon carbide member was produced in the same manner as in Example 1 except that the weight ratio of silicon carbide powder to nylon 12 was 100:10 to obtain the raw material. Furthermore, in the same manner as in Example 1, silicon on the surface of the reaction-sintered silicon carbide member was removed, and various evaluations were performed after processing into a desired shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com