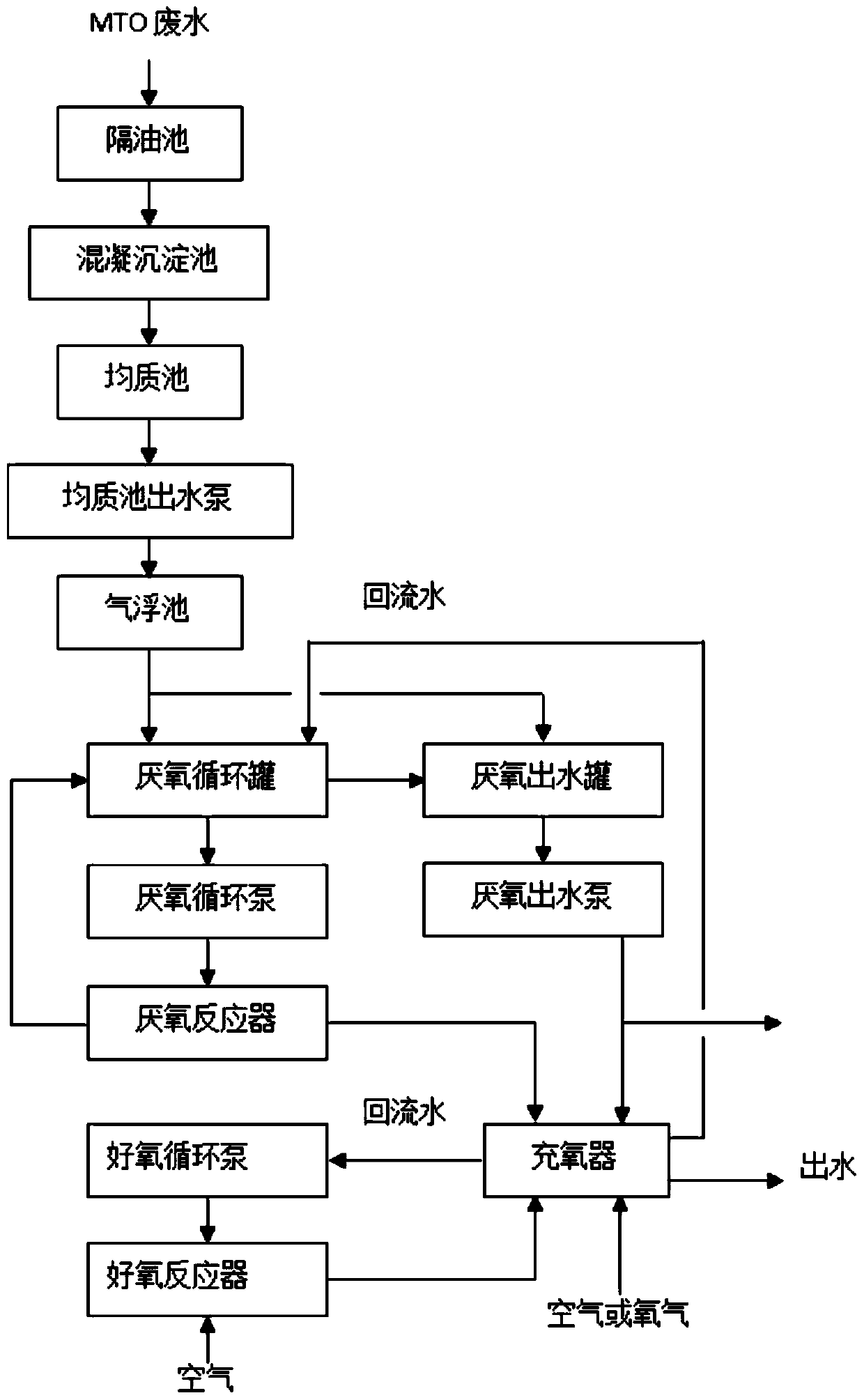

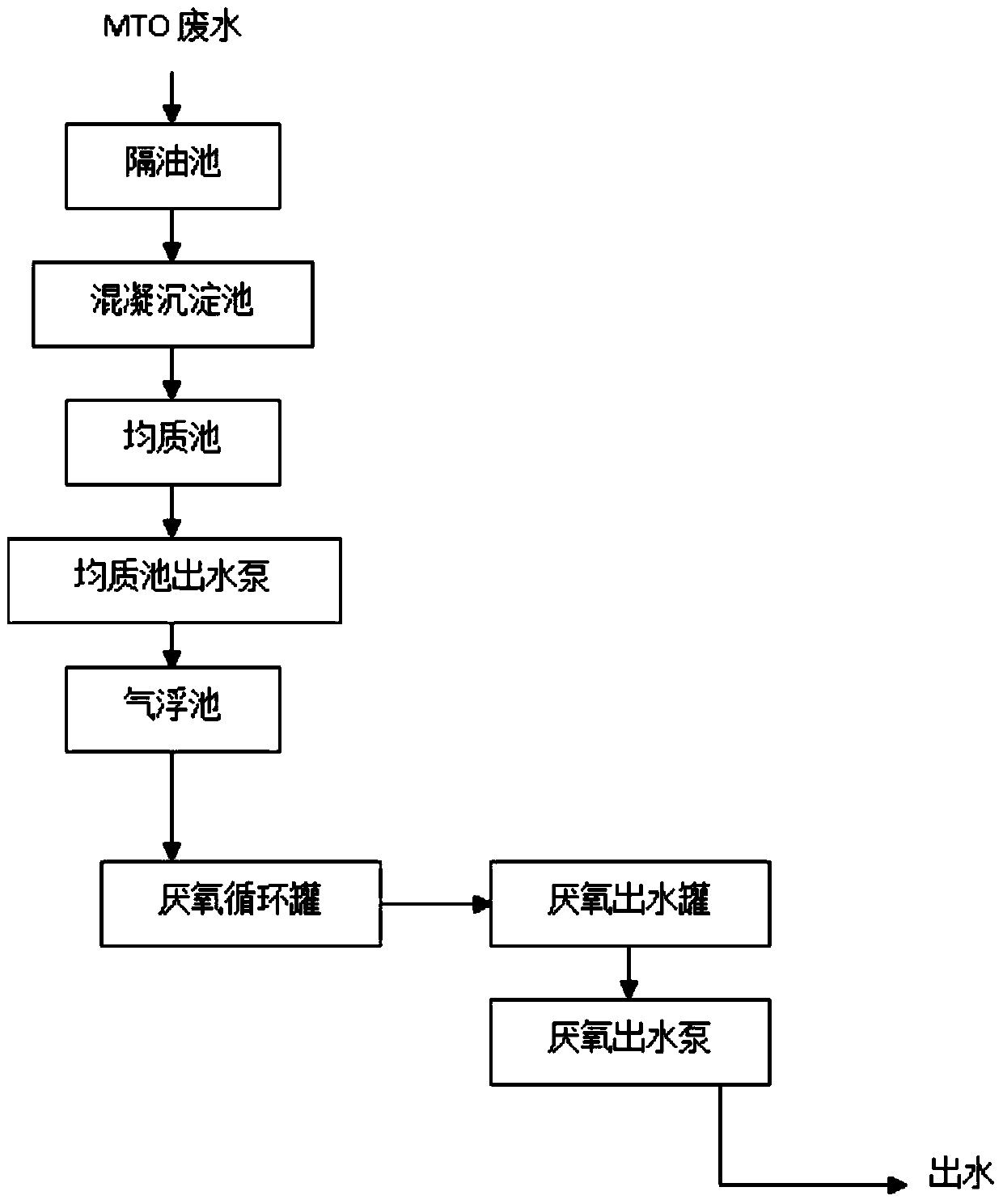

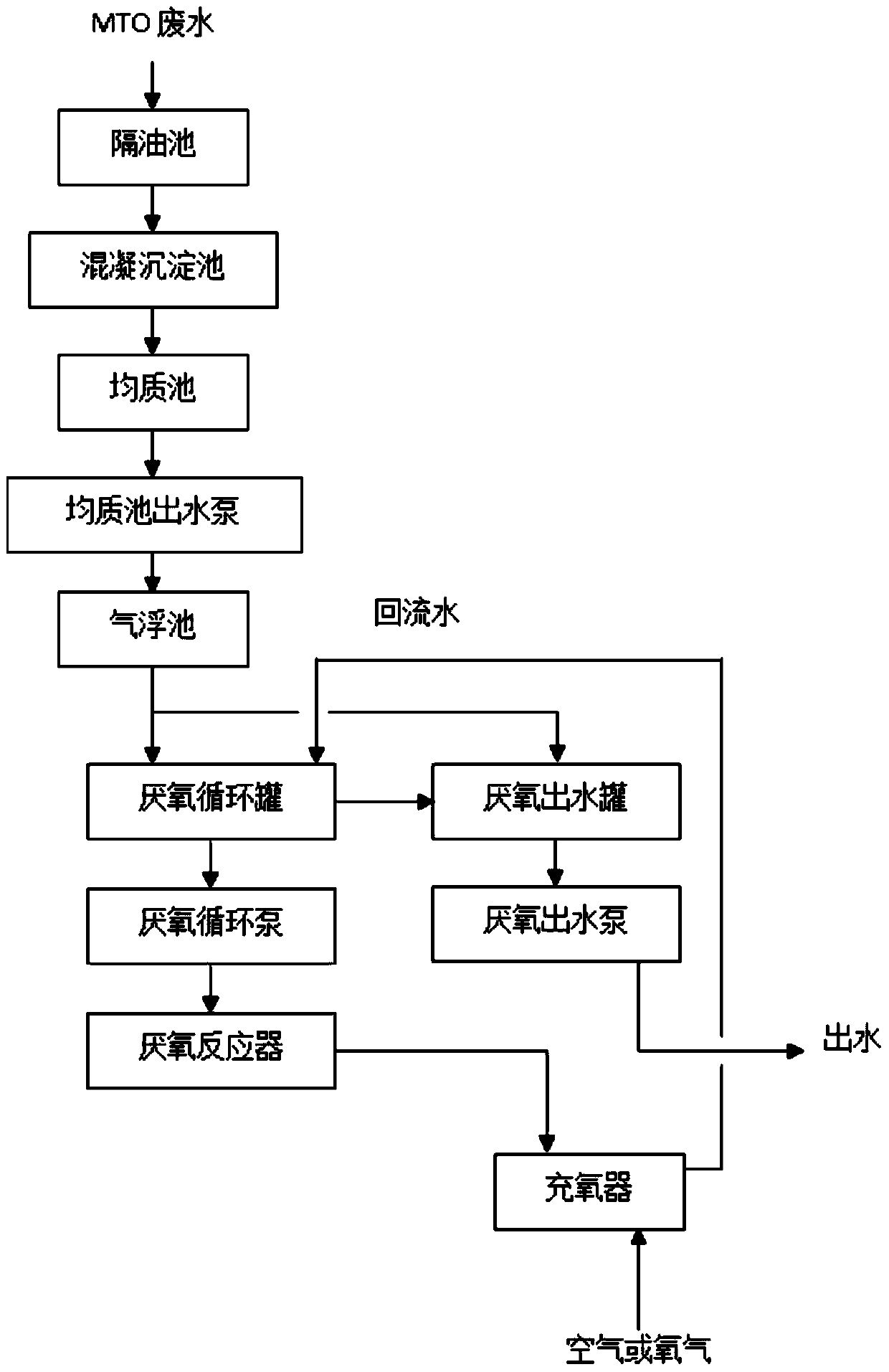

A methanol-to-olefin wastewater treatment device and its start-up method

A technology for methanol to olefins and wastewater treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of good water quality, less sludge inoculation and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] The COD of MTO wastewater is 1000-1200mg / L, and the suspended matter content is 50-200mg / L. The content of suspended solids in the effluent of the coagulation sedimentation tank is 30-100mg / L. The COD of the effluent from the homogeneous tank is 1050-1150mg / L, and the suspended solids content is 50-80mg / L. The content of suspended solids in the effluent of the air flotation tank is less than 50mg / L.

[0154] The anaerobic reactor is sequentially provided with a gas-water distribution area, a packing area and a water outlet area from bottom to top. The air-water distribution area is equipped with a supporting layer, a water distributor and an air distributor. Among them, the perforated tubular water distributor is located in the lower part of the supporting layer, and the perforated tubular air distributor is located in the upper part of the supporting layer. The supporting layer is composed of graded ceramic balls: the particle size of the bottom ceramic ball is 25mm ...

Embodiment 2

[0159] The COD of MTO wastewater is 500-2000mg / L, and the suspended matter content is 50-300mg / L. The content of suspended solids in the effluent of the coagulation sedimentation tank is 30-150mg / L. The COD of the effluent from the homogeneous tank is 800-1500mg / L, and the content of suspended solids is 50-100mg / L. The content of suspended solids in the effluent of the air flotation tank is lower than 80mg / L.

[0160] The anaerobic reactor is sequentially provided with a gas-water distribution area, a packing area and a water outlet area from bottom to top. The air-water distribution area is equipped with a supporting layer, a water distributor and an air distributor. Among them, the perforated tubular water distributor is located in the lower part of the supporting layer, and the perforated tubular air distributor is located in the upper part of the supporting layer. The supporting layer is composed of graded ceramic balls: the particle size of the bottom ceramic ball is 13...

Embodiment 3

[0165] The COD of MTO wastewater is 300-1500mg / L, and the suspended matter content is 50-200mg / L. The content of suspended solids in the effluent of the coagulation sedimentation tank is 30-100mg / L. The COD of the effluent from the homogeneous tank is 500-1200mg / L, and the content of suspended solids is 50-80mg / L. The content of suspended solids in the effluent of the air flotation tank is less than 50mg / L.

[0166] The anaerobic reactor is sequentially provided with a gas-water distribution area, a packing area and a water outlet area from bottom to top. The air-water distribution area is equipped with a supporting layer, a water distributor and an air distributor. Among them, the perforated tubular water distributor is located in the lower part of the supporting layer, and the perforated tubular air distributor is located in the upper part of the supporting layer. The supporting layer is composed of graded ceramic balls: the particle size of the bottom ceramic ball is 25mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com