Recycling process for waste activated carbon generated in acetaminophen refining working section

A paracetamol, waste activated carbon technology, applied in the petroleum industry, filter regeneration, water/sludge/sewage treatment, etc., can solve the problems of high requirements for equipment and supporting facilities, harsh oxidation conditions, and high treatment costs, reaching The effect of reducing pollutant discharge, reducing consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

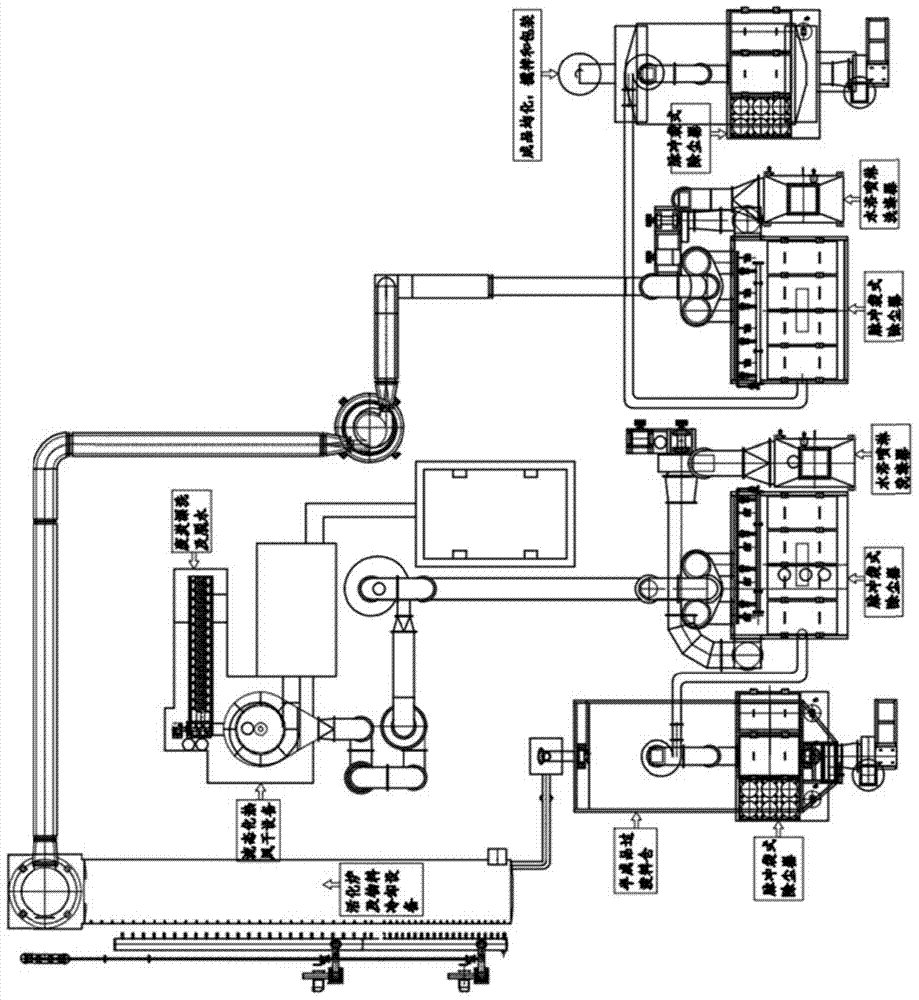

Image

Examples

Embodiment

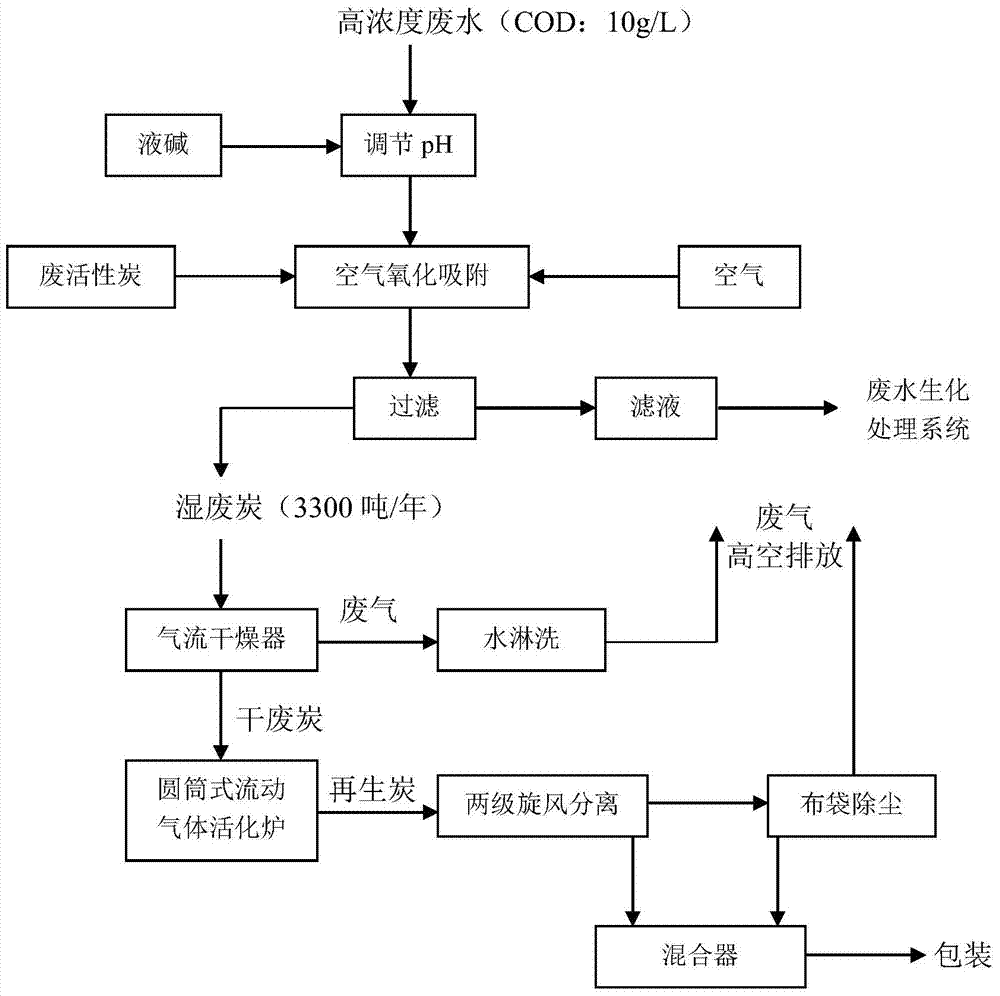

[0022] 1. Wastewater pretreatment process:

[0023] ① Adjust the pH of the wastewater to about 5-8 (preferably 7) with alkali,

[0024] ②The oxidation-polymerization reaction is carried out by introducing air at a temperature of 30-90°C (preferably 50-80°C),

[0025] ③ Add a certain amount of waste carbon (10-20% w / v) to adsorb the formed oxidation polymerization product,

[0026] ④ After filtering the activated carbon, the color of the waste liquid becomes lighter obviously, from dark brown to light yellow or light red, and the COD also drops significantly. The remaining COD in the pretreated waste liquid is basically formed by acetic acid after analysis, and can enter the biochemical treatment system .

[0027] ⑤The waste charcoal that has been pretreated by wastewater enters the waste charcoal regeneration system.

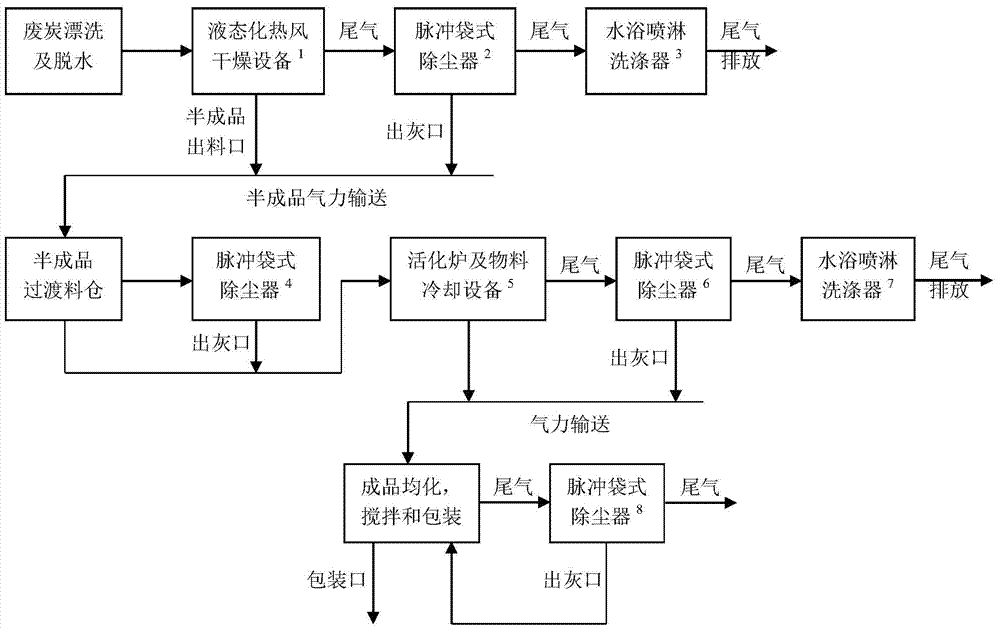

[0028] 2. Waste carbon regeneration process:

[0029] ① The waste activated carbon is screened by a screening machine to remove large impurities in the wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com