Heat exchange mechanism used for sea water desalination system

A technology of heat exchange mechanism and heat exchange tubes, which is applied in seawater treatment, general water supply saving, refrigerators, etc., can solve the problems of high energy consumption and high cost of seawater desalination technology, improve recycling rate, avoid heat loss, and improve The effect of system yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

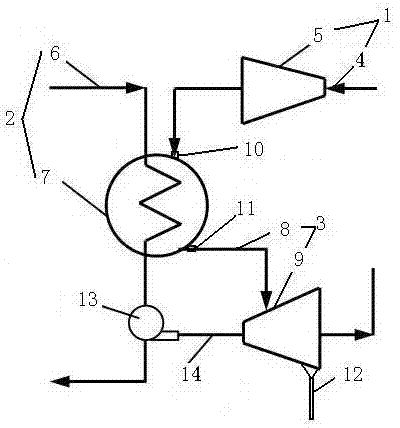

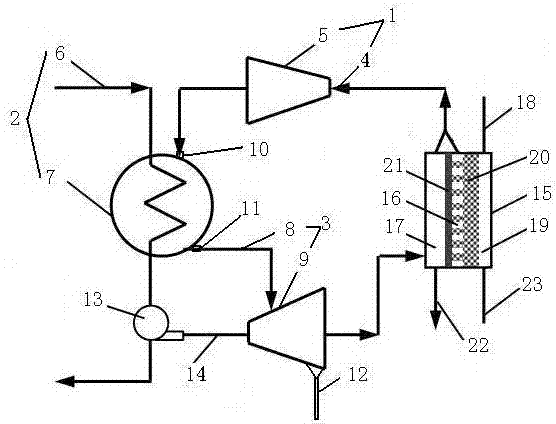

[0017] A heat exchange mechanism for a seawater desalination system as shown in the figure is characterized in that it includes a decompression mechanism 1, a heat exchange mechanism 2 and a pressure boosting mechanism 3, and the decompression mechanism 1 includes a decompression pipeline 4 and an expansion valve 5. The heat exchange mechanism 2 includes a heat exchange pipeline 6 and a heat exchanger 7, the boost mechanism 3 includes a boost pipeline 8 and a compressor 9, and the heat exchanger 7 is arranged on the heat exchange pipeline 6 above, including a heat exchange inlet 10 and a heat exchange outlet 11, a thermal working fluid circulates in the heat exchange pipeline 6, and the thermal working medium is a heat source, and the expansion valve 5 is arranged on the depressurization pipeline 4, so One end of the step-down pipeline 4 communicates with the heat exchange inlet 10 of the heat exchanger 7, the compressor 9 is arranged on the boost pipeline 8, and one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com