Separation equipment for grinding system of roller press

A roller press and sorting technology, which is applied to the separation of solids from solids by air flow, solid separation, grain processing, etc., can solve the problems of high power consumption in system operation, high material conveying height, and heavy civil engineering workload. , to achieve the effect of increasing system output, reducing system air volume, and reducing material over-grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

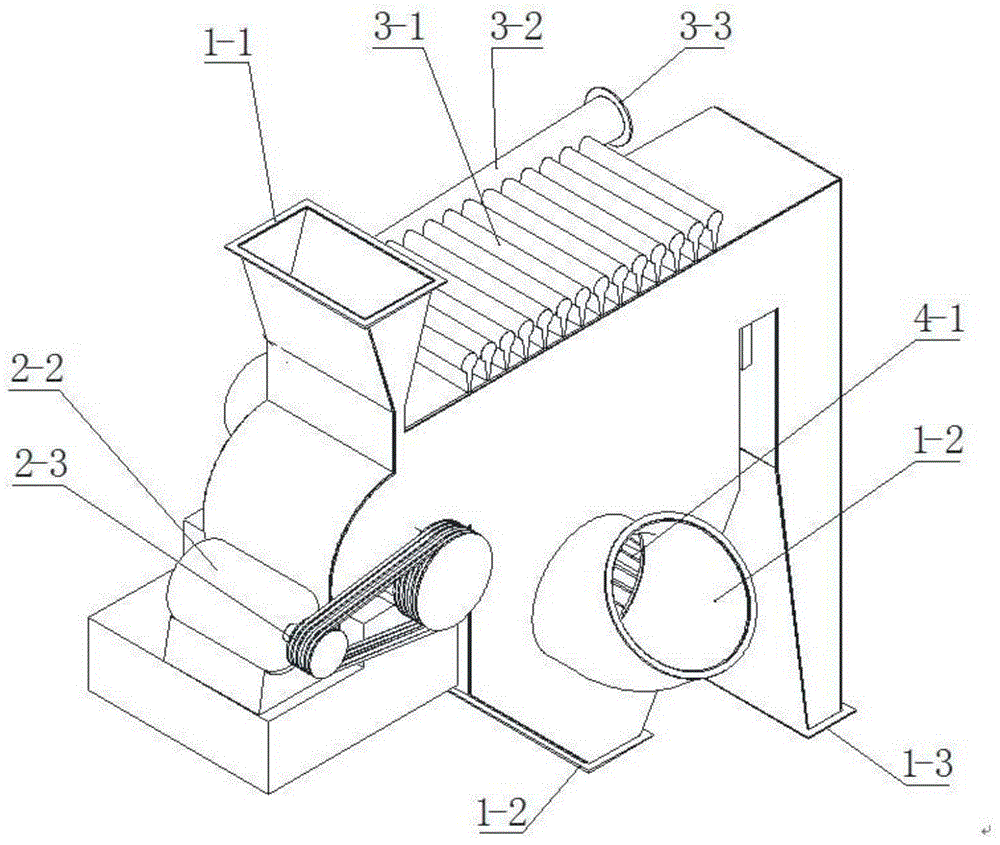

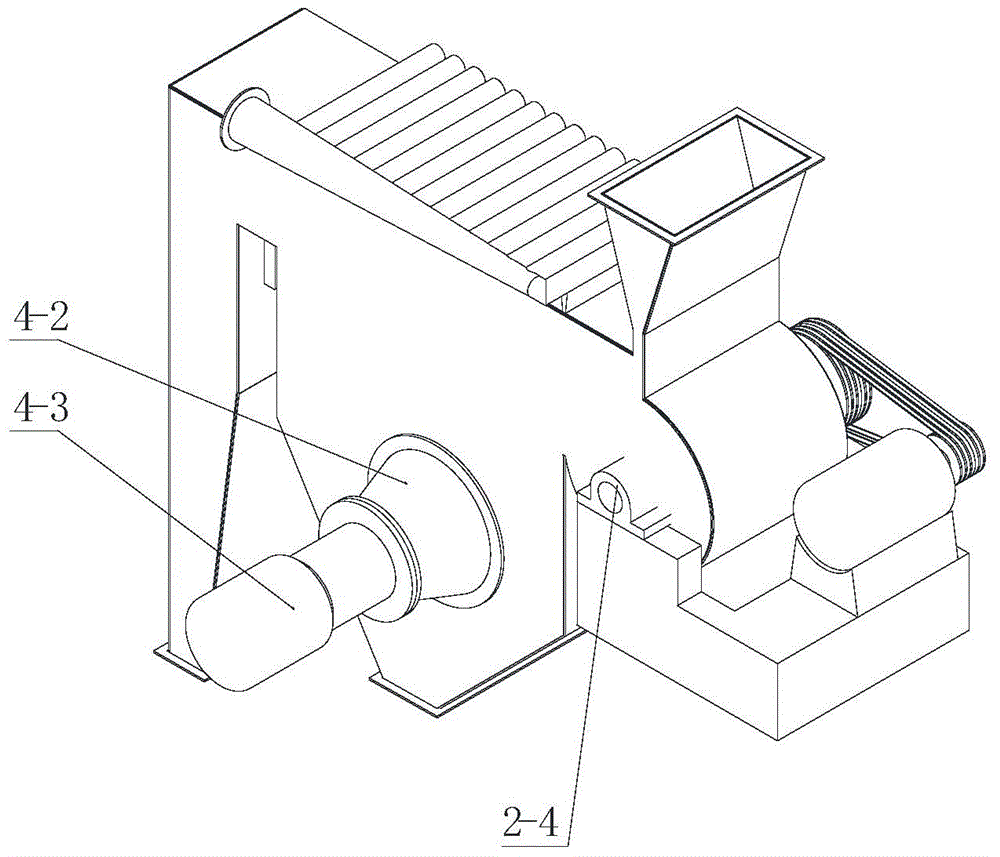

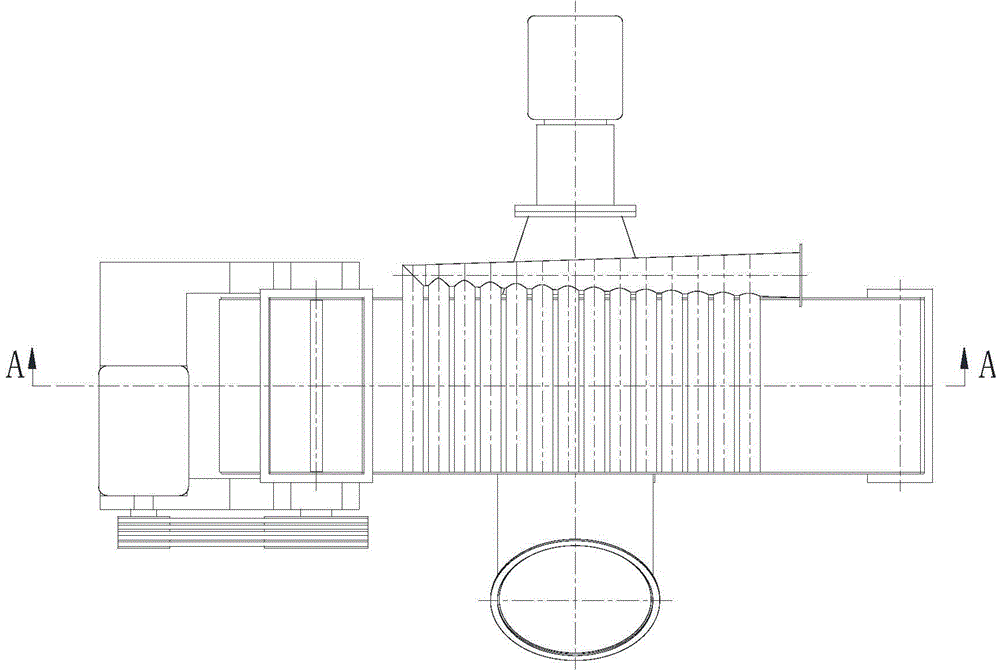

[0024] In order to make the content of the present invention more obvious and understandable, the following in conjunction with the attached Figure 1-Figure 4 and specific implementation methods for further description.

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] This embodiment discloses a device for sorting grinding materials of a roller press, including a shell, a powerful dispersing component, a pneumatic screening device, a sorting component, a semi-finished product adjusting component, and a material receiving curtain 6-1 And roller press recycling material collection curtain 6-2.

[0027] The powerful dispersing part 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com