Belt conveying type moving sidewalk

A technology of moving walks and belts, used in escalators, transportation and packaging, etc., to achieve the effect of increasing friction coefficient, simple structure and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

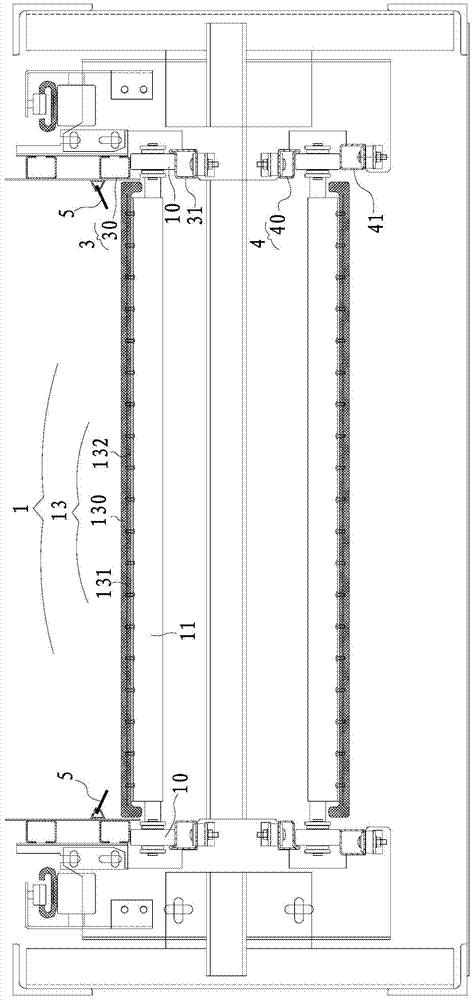

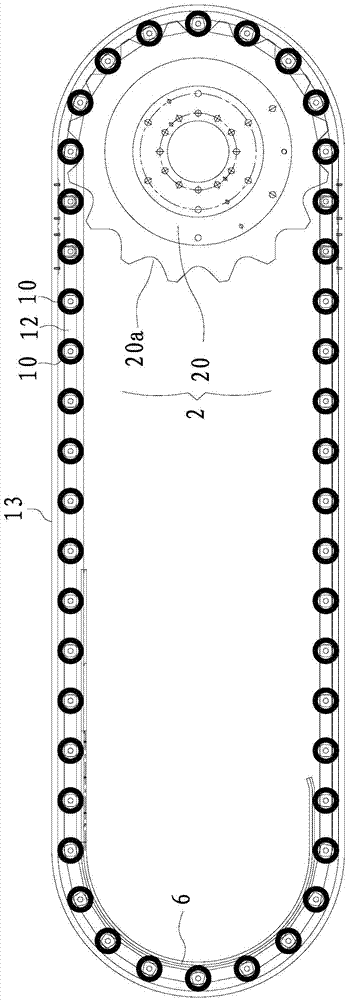

[0022] Such as Figure 1 to Figure 3 As shown, the belt-conveyed moving walk provided by this embodiment includes a chain plate 1 and a driving mechanism 2. Roller 10, the wheel seat 11 that is used to connect a plurality of rollers 10 on both sides one by one, is used to connect the two ends of every two adjacent wheel seats 11 respectively to form the connecting part 12 of ring shape, and is arranged on the wheel The conveyor belt 13 on the seat 11 and between the rollers 10 on both sides.

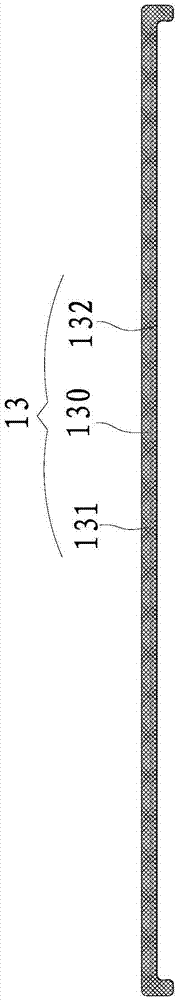

[0023] Specifically, the conveyor belt 13 includes a tread surface 130 positioned on the outer layer for people to walk on, a spring steel plate 131 positioned at the middle layer, and a connecting panel 132 positioned at the inner layer, wherein the tread surface 130 is made of rubber or polyurethane; The steel plate 131 is fixedly connected. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com