ejection arresting device

A technology of blocking device and cylinder, which is used in stopping device, launch/drag transmission device, etc., can solve the problems of complex structure and poor sealing effect, and achieve the effect of reducing the length of the cylinder, improving the sealing performance, and being easy to manufacture and install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

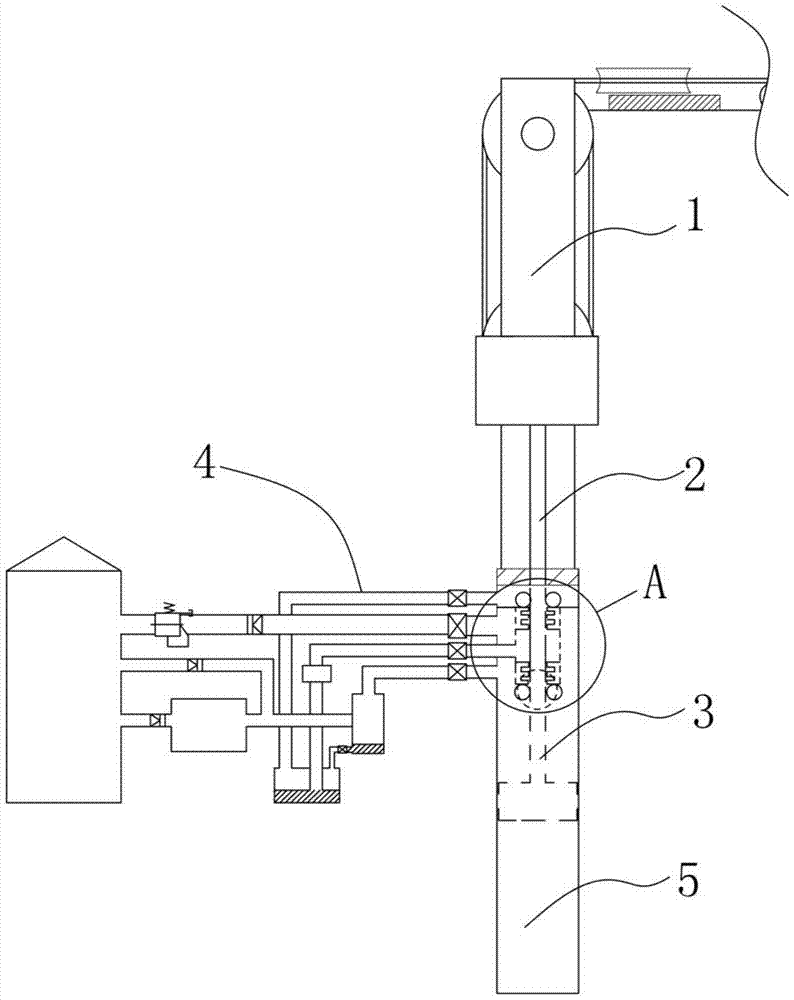

[0021] Such as Figure 1 to Figure 4 As shown, an ejection arresting device of the present invention includes a pulley block 1, a drawbar 2, a high-pressure gas storage device 4 and a cylinder 5; the pulley block 1 is connected to several cylinders 5 through the drawbar 2; the cylinder 5 includes a piston 3; the piston 3 is connected to the draw rod 2; a high-pressure liquid sealing chamber 6 is provided at the joint between the interior of the cylinder 5 and the draw rod 2; the upper and lower ends of the high-pressure liquid sealing chamber 6 are provided There is a labyrinth seal cavity 7, which communicates with the high-pressure liquid seal cavity 6; the high-pressure liquid seal cavity 6 communicates with the high-pressure gas storage device 4; the other end of the pulley block 1 is connected with the ejector.

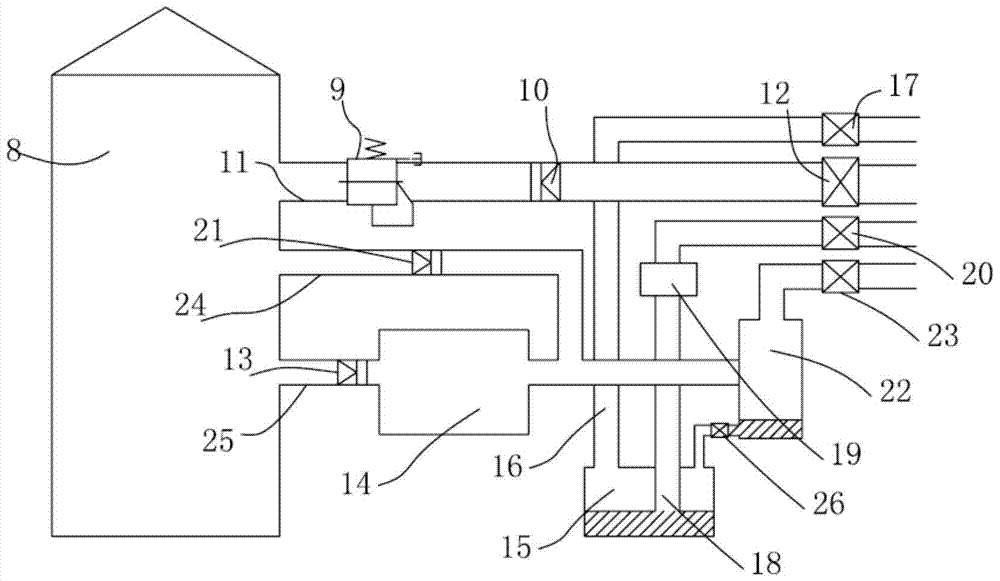

[0022] The high-pressure gas storage device 4 includes a high-pressure gas storage tank 8 and a liquid storage tank 15; the high-pressure gas storage tank 8 comm...

Embodiment 2

[0027] Such as Figure 7 and Figure 8 Mount the ejection arrester on the transport vehicle as shown. Drive the transport vehicle 37 to a predetermined position, push the ejection blocking device to a predetermined height angle with a hydraulic cylinder 38, turn the ejection frame 40 to a predetermined azimuth angle with the turntable 39, and slide the bottom of the ejection frame 40 to the predetermined position with the ejection frame slide frame 41 On the ground, slide the rear seat baffle plate 42 into the base groove dug in advance to carry out the ejection work, and the ejection principle is consistent with Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com